C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

60

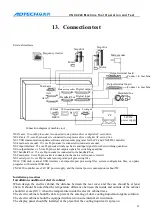

DC relay (24VDC)

Cable

between

the

system

and

strong

electricity cabinet

Cable

between

the

system and machine

tool

the cables in group B as far as possible from

group C

Cable

between

the

system and servo drive

Position

feedback

cable

Position encoder cable

Handwheel cable

C

Other

cables

for

shielding

Bind cables in group C separately from those in

group A, or shield the cables in group C; keep at

least 10cm between the cables in group B and

group C and use twisted pair cables

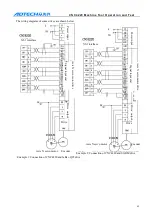

13.1.

Motor drive connection test

CNC4220 numerical control system integrates two step (or servo) motor drive interfaces (XS1 axis X

and XS2 axis Z); control mode: dir pulse (D+P); each interface pin has same function.

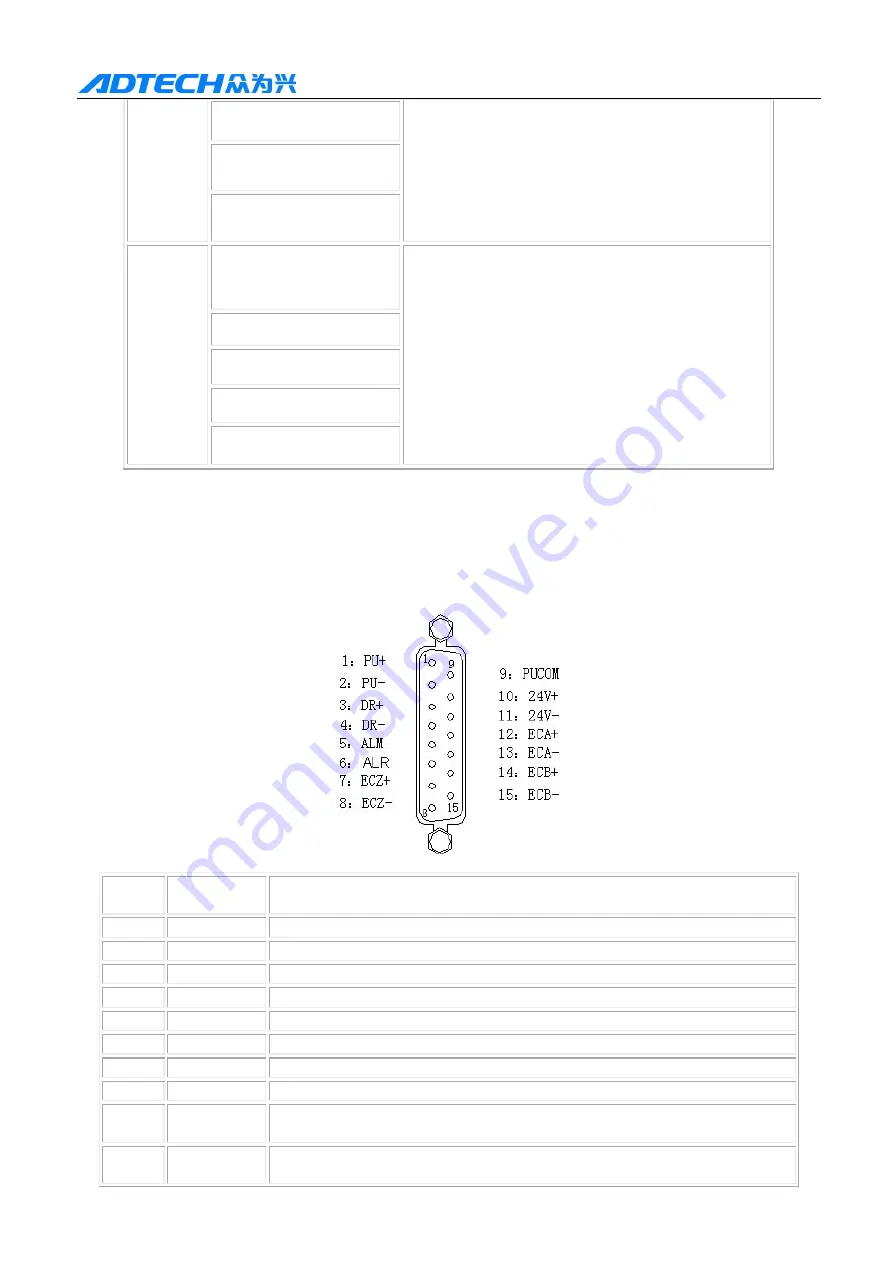

1. Function of drive interface pin

D efi n iti o n of dr i ve i nt er fa c es

X S1 a n d X S2 i nt er fa c e

Wire

No.

D efi n iti o n

sy mb o l

F u nct i o n

1

PU+

P uls e si g na l +

2

PU-

P uls e si g na l -

3

D R+

D ir ect i o n si g na l +

4

D R-

D ir ect i o n si g na l -

5

A LM

Ser v o a la r m si g na l a x is X : IN 3 4 , a x is Y: IN 3 5

6

A LR

Ala r m c lea r i n g a x is X : O U T2 4 , a x is Y: O U T2 5

7

E CZ+

E n c o der p ha se Z i n p ut +

8

E CZ-

E n c o der p ha se Z i n p ut -

9

PU CO M

Positive end of internal 5V power supply; can’t connect to external power

supply (drive for single end input)

10

2 4 V+

I nt er na l 2 4 V p o wer s u p pl y, c o n n ec te d dir e ctl y t o t h e 2 4 V p o w er

su p p l y o f t h e c o n tr o ll er