C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

69

N50

M30.

Set the error compensation of reverse clearance to 0 before measuring;

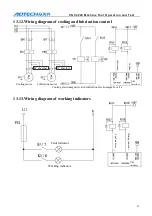

For single section program, find measurement reference A after positioning for two time,

record current data, run 1mm in same direction and then run 1mm to point B in reverse

direction to read current data.

Error compensation of reverse clearance = | data recorded by point A–data recorded by

point B |; if the clearance error isn’t 0, please modify the values of parameter 43 and 44

(unit: pulse); if the clearance is too big, increase the values of parameter 43 and 44, or

else decrease the values until the error compensation of reverse clearance is 0.

Note: Re-check the reverse clearance when the machine tool has been used for three months.

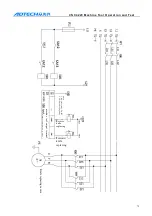

13.5.

Drive protection settings and checking

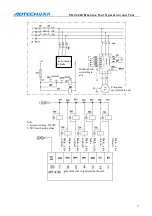

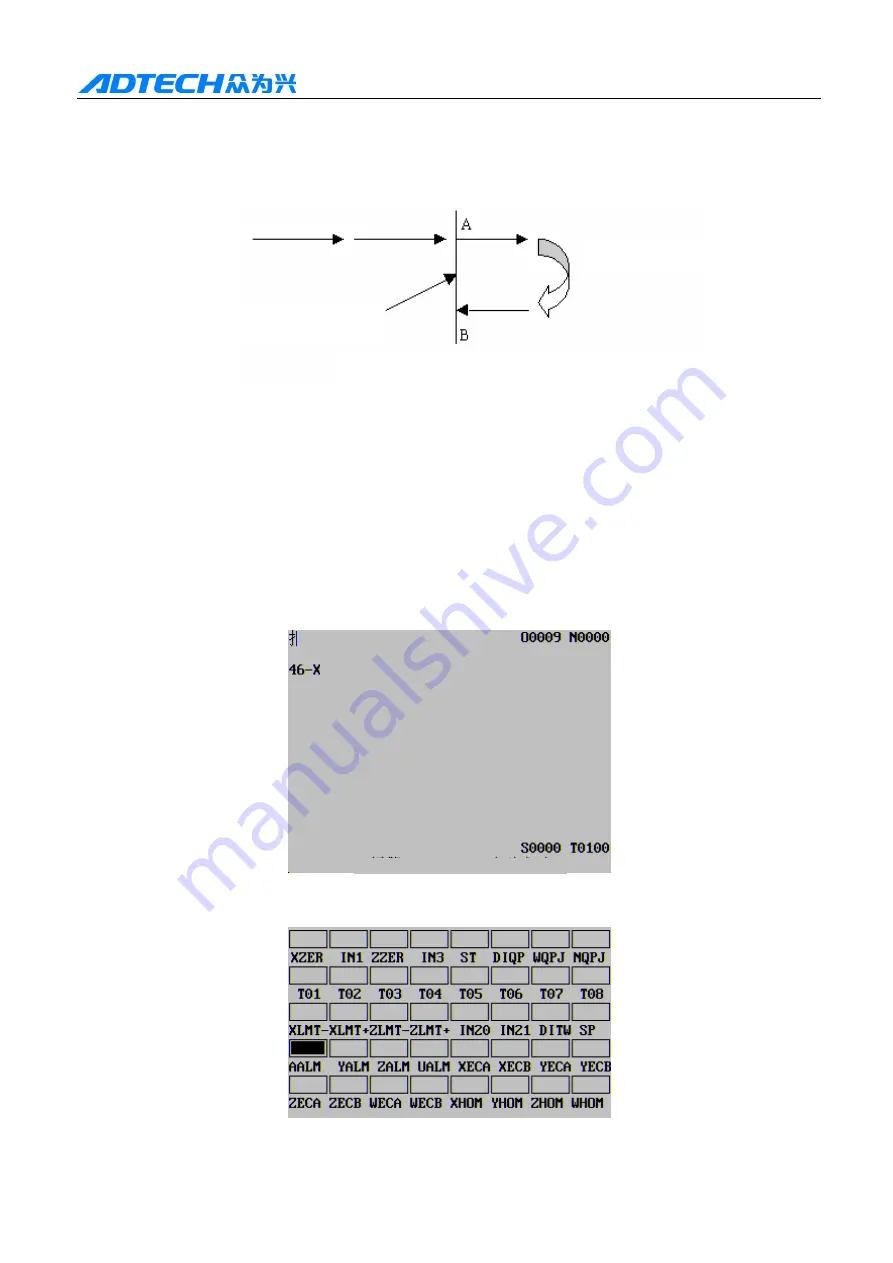

Drive alarm signal

The drive alarm function is always on and can’t be disabled, but the alarm effective level can be set in

the parameters. When the system is working and detects drive alarm signals, it compares with the

effective level set by the parameters and displays the corresponding alarm signals if it accords with the

parameter value. In auto mode, it stops running and sends alarm. Press the Diagnosis key to view the

alarm info and check the reason of the alarm. When the fault is eliminated, press the Reset key to clear

the alarm.

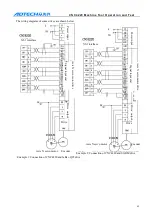

Axis X alarm info

Input point state

Axis X alarm signal AALM input valid

Reverse position

Position of reading data

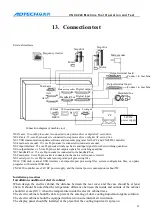

Diagram of reverse clearance measurement method

Alarm info

Axis X positive direction overtravel

Alarm Auto mode