C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

70

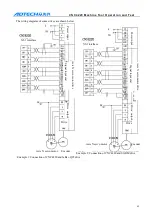

Parameters: system parameter 30 and 31, axis X and axis Z alarm level. Default: “0”, low level is

effective; if the alarm is high output level, please change this parameter to “1”.

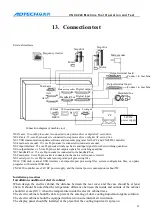

13.6.

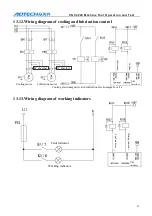

Main axis encoder

Wiring diagram of main axis encoder

Definition of main axis encoder interfaces Rotation encoder

Parameters

System parameter 60: wire number of main axis encoder; please set according to the value marked

on the encoder label.

13.6.1

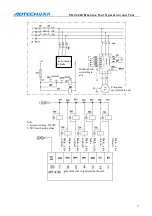

TROUBLESHOOTING FOR MAIN AXIS ENCODER

No main axis rotation display: Check whether the cable connection is normal; if yes, enter the main

axis encoder test interface in the diagnosis interface. Rotate the main axis manually, the main axis

encoder counter takes count in normal condition, and the stats of phase A and phase B flash. If there is

no change, please check whether the power supply of the encoder interface is normal. If yes, check the

differential output signal of phase A and phase B. During low speed rotation, the voltage changes a

little. If the power supply is normal and the driving voltages of phase A and phase B change, the input

port of machine tool may be damaged. Please contact the system manufacturer.

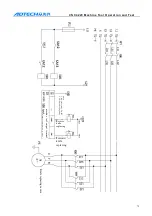

The system doesn’t respond to any operation when running screw thread instruction

Reason: when lathing screw thread, system checks the signal of screw head (encoder axis Z signal).

If the rising and falling of phase Z signal aren’t detected, the program stays in circle detection state

(because the phase Z signal of the encoder is very narrow) and doesn’t respond to the key-pressing.

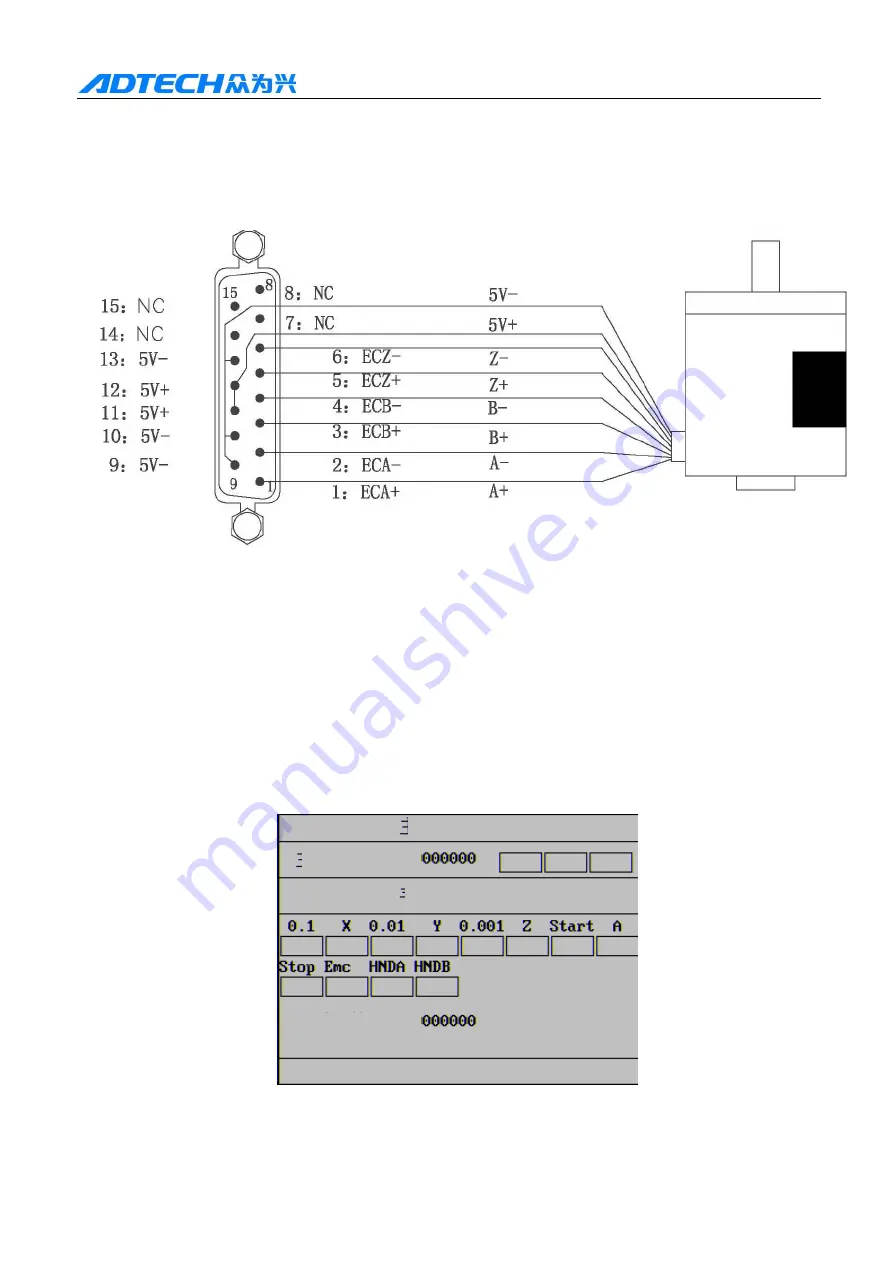

Main axis encoder test

Main axis encoder

Handheld box test

Handwheel