C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

75

S10

1

0

1

0

S11

1

0

1

1

S12

1

1

0

0

S13

1

1

0

1

S14

1

1

1

0

S15

1

1

1

1

13.7.6

TROUBLESHOOTING FOR MAIN AXIS CONTROL

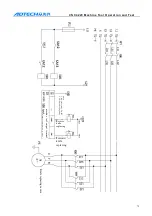

This part mainly involves the settings of frequency inverter, few involves the parameter setting of

machine tool control, and except the analog voltage, the state change of output signals of machine tool

controller can be checked in output point state interface.

13.8.

Chuck control

13.8.1

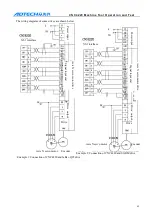

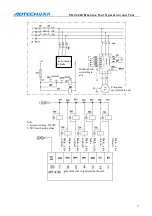

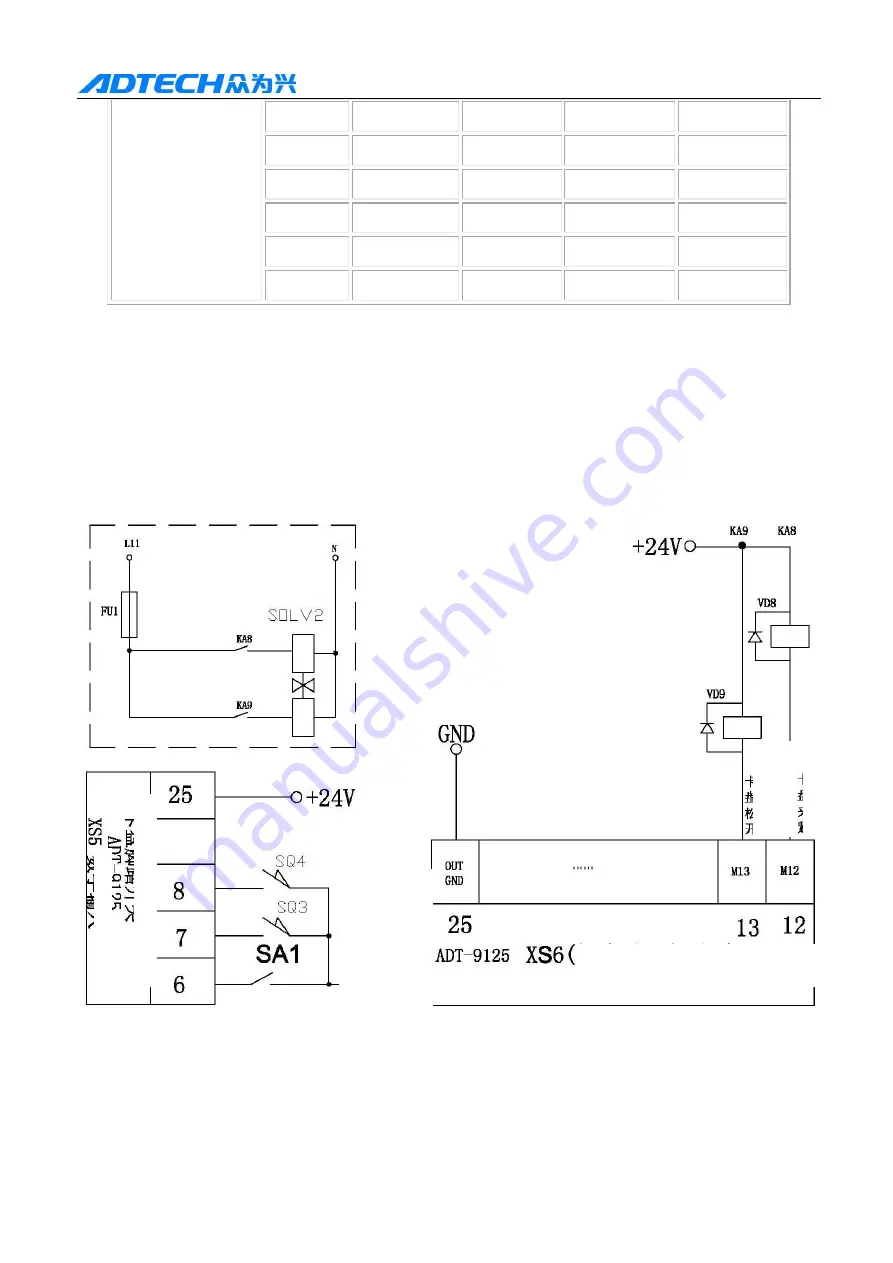

WIRING DIAGRAM

13.8.2

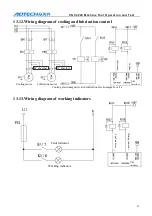

CHUCK PARAMETER SETTING

Check the clamping setting of chuck is “0” or “2” (do not check the clamp in position signal). The

shadow part is the chuck clamping time and controlled by the parameters. The output time sequence is

shown in the figure below.

C

huc

k c

la

m

p

ed

Note:

1. KA center relay, DC24V

2. VD Freewheeling diode

C

huc

k

re

le

as

ed

(machine tool output terminal board)

Clamping

signal

Release signal

C

huc

k f

o

ot

s

w

itc

h

D

igi

ta

l i

nput