C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

87

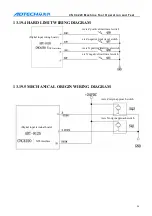

origin

34

Effective level of axis Z

origin

0-1

0

35

Origin direction of axis X

0-1

0

0: origin in negative

direction; 1: origin in

positive direction

36

Origin direction of axis Z

0-1

0

0: origin in negative

direction; 1: origin in

positive direction

37

High speed of axis X origin

1-9999.99

7000

mm/min

38

High speed of axis Z origin

1-9999.99

7000

mm/min

39

Low speed of axis X origin

1-9999.99

200

mm/min

40

Low speed of axis Z origin

1-9999.99

200

mm/min

41

Axis X reference point

coordinates

-9999.999-9999.

999

0.000

mm

42

Axis Z reference point

coordinates

-9999.999-9999.

999

0.00.000

mm

43

Axis X reverse clearance

compensation

0-2 000

0

Pulse

44

Axis Z reverse clearance

compensation

0-2 000

0

Pulse

45

Knife alignment mode

0-2

0

Alignment mode=0: fixed

alignment mode

Alignment mode =1: test

cutting mode

Alignment

mode

=2:

mechanical origin mode

46

System knives

0-32

4

47

Knife position signal level

0-1

1

48

Knife rack lock signal level

0-1

1

49

Maximum knife replacing

time

1-65536

40000

ms

50

Knife replacing delay

1-65535

200

ms

51

Reverse lock time of knife

rack

1-65535

4000

ms

No.

Function

Range

Default

Unit

Remark

52

Effective control position of

chuck function

0-1

0

0: ineffective

1: effective

53

Chuck mode

0-3

0

0: continuous output of

external chuck signal

1: continuous output of

internal chuck signal

2: pulse output of external

chuck signal

3: pulse output of internal

chuck signal

54

Check chuck clamping

0-3

0

1: check releasing and

clamping signals; 0: do

not check releasing and

clamping signals; 2: check

clamping signal; 3: check

releasing signal

55

Chuck in position signal

level

0-1

0

56

Chuck clamping time

1-65536

1000

ms

57

Tailstock function control

0-1

0

58

Main axis control mode

0-2

1

1: analog speed regulation

0: speed regulation for

switching

quantity