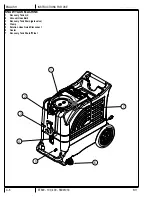

A - 10

ET600 - 100, 400 - 56091033

8/11

INSTRUCTIONS FOR USE

REVISED DATE

ENGLISH

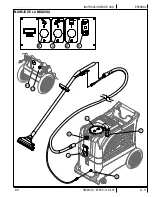

OPERATING THE MACHINE

1

Follow the instructions in the

Preparing the Machine for Use

section of this manual.

2

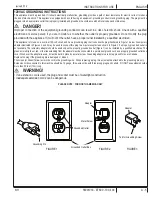

Turn off all the switches. Plug the power cords into properly grounded outlets. Do not connect both cords to the same outlet; the green,

Circuit Indicator Light

(E)

on the switch plate should light up. If the indicator light does not come on, try different outlets until it does. Do not

connect both cords to the same outlet.

3

Attach the priming hose to the machine and place the open end into the solution tank.

4

Turn ON the solution pump

(C)

and let it run until the pump is fully primed (approximately 30 seconds to 1 minute). Once the pump is primed,

turn off the pump and remove the priming hose.

NOTE:

If priming is dif

fi

cult, place the open end of the priming hose into the Vacuum inlet

hose barb, and turn the vacuum on. Use your hand to block the open area in the hose barb. This will allow the pump and the vacuum to work

together to get the water moving.

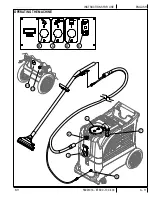

5

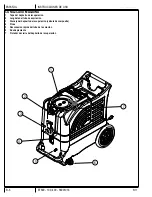

Connect a solution line to the Solution Hose Quick Disconnect

(5)

. Attach the other end of the solution line to the cleaning tool.

6

Connect a vacuum hose to the Vacuum Hose Barb

(2)

. Attach the other end of the vacuum hose to the cleaning tool.

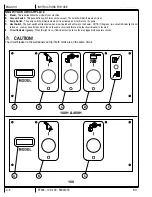

7

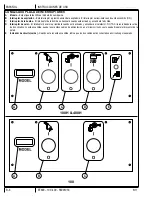

To use heated water for cleaning, press the Heat Switch

(D)

on. Wait two minutes for the heat exchanger to reach temperature.

8

Press the Pump Switch

(C)

to ON (I).

9

Press the Vacuum Switch

(B)

to ON (I).

10

Spray through your tool a few times to

fi

ll the lines with solution. Begin cleaning.

11

Note for 400H models only:

To adjust the solution spray pressure; rotate the Pressure Adjustment Knob

(13)

clockwise to increase pressure

and counterclockwise to decrease pressure. The pump spraying pressure will be observable at the Pressure Gauge

(15)

while spraying. Make

sure the cleaning tool is spraying when adjusting the pressure, otherwise the pressure reading will be inaccurate.

12

Watch

the

fl

uid entering the Recovery Tank Lid

(1)

. If there is a large amount of suds in the recovery tank, add a defoamer chemical to the

recovery tank.

CAUTION!

• Empty the recovery tank before the

fl

uid or foam enters the vacuum motor.

• If foam or liquid escapes from the machine, switch off immediately.

CAUTION!

Always make sure the

fl

oat is clean and travels freely before turning on the machine. A

fl

oat that is stuck will cause the

vacuum motor to suck in water, resulting in vac motor damage.

13

The recovery tank has a Recovery Tank Shutoff Float

(7)

to block the vacuum system when the recovery tank is full. You can tell when the

fl

oat

closes by the sudden change in the sound of the vacuum motor. When the

fl

oat closes, the recovery tank must be emptied. The machine can

continue to dispense solution, but

will not

pick up water with the

fl

oat closed.

14

Monitor the water level in the solution tank. Do not let the pump run dry. When the solution tank gets low, turn off the pump and the vacuum

motor, re

fi

ll the solution tank with water and the proper ratio of cleaning detergent. Empty the recovery tank and continue cleaning.

15

When the operator has completed the job; vacuum all unused solution from the solution tank into the recovery tank, turn off the pump, vacuum

motor and heat exchanger. Unplug the machine.

16

Push the machine to a designated waste water “DISPOSAL SITE” and empty the recovery tank. Drain the recovery tank by opening the drain

gate

(3)

over a drain or a bucket.

17

Follow the instructions in the

After Using the Machine

section of this manual.