10

9098827000(2)2010-12

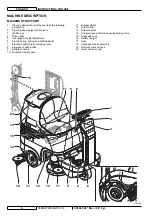

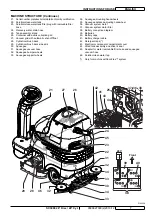

SC3000 26” Disc / 28” Cyl.

ENGLISH

INSTRUCTIONS FOR USE

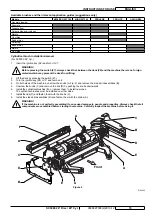

Technical data for machines with cylindrical brush deck

Description

28” Cyl.

Cylindrical brush size (diameter x length)

5.7 x 27.2 in (145 x 690 mm)

Weight without batteries and with empty tanks

396.8 lb (180 kg)

Maximum weight with batteries, full tanks and operator (75 kg) (GVW)

994.3 lb (451 kg)

Cylindrical brush motor power

2 x 0.8 HP (2 x 600 W)

Cylindrical brush speed

720 rpm

Cylindrical brush pressure

77.1 lb (35 kg)

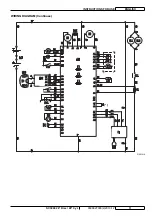

WIRING DIAGRAM

Key

BAT

24 V battery box

BE

Flashing light (optional)

BRK

Electromagnetic brake

BZ1

Reverse gear warning buzzer/horn

C1

Battery connector

C2

Battery charger main connector

C3

Battery charger sub-connector

C4

Brush deck connector

CH

Battery charger (optional)

EB1

Function electronic board

EB2

Display electronic board

EB3

Dashboard instrument electronic board

ES1

Brush electromagnetic switch

EV1

Solenoid valve

F1

Brush deck fuse

F2

Main electronic board fuse

F3

Signal circuit fuse

F4

Actuator fuse

K1

Ignition switch

M1.1,2 Brush motor

M2

Vacuum system motor

M3

Drive system motor

M4

Detergent pump (optional)

M5

Brush deck actuator motor

M6

Squeegee actuator motor

m0

Squeegee actuator position 0 microswitch

m1

Squeegee actuator position 1 microswitch

m2

Squeegee actuator position 2 microswitch

PR1

Solution/clean water level pressure switch

RV1

Drive pedal potentiometer

SW1

Driver’s seat microswitch

Color codes

BK

Black

BU

Blue

BN

Brown

GN

Green

GY

Grey

OG

Orange

PK

Pink

RD

Red

VT

Violet

WH

White

YE

Yellow

For SC3000 26” Disc version only

(*)

Summary of Contents for 9087266020

Page 2: ......