18

9098827000(2)2010-12

SC3000 26” Disc / 28” Cyl.

ENGLISH

INSTRUCTIONS FOR USE

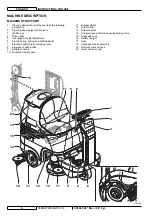

MACHINE OPERATION (SCRUBBING/DRYING)

Start the machine as shown in the previous paragraph.

1.

If necessary, adjust the solution quantity by pressing the switches (59 and 60).

2.

If necessary, to reduce the noise, turn on the mute function by pressing the switch (55).

3.

NOTE

It is suggested to use the mute function only on smooth fl oors without joints.

NOTE

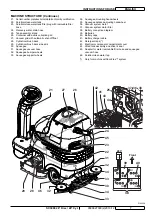

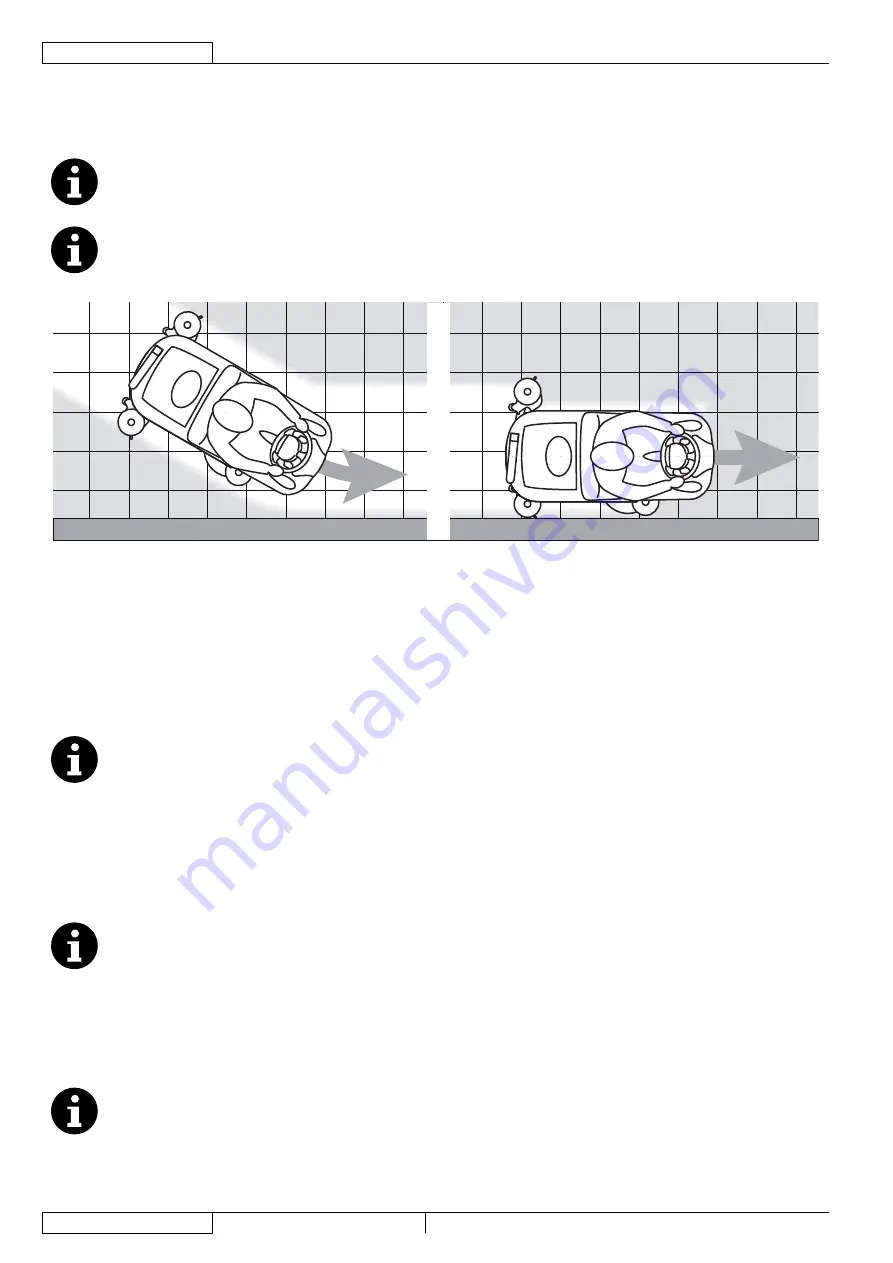

For correct scrubbing/drying of fl oors at the sides of the walls, Advance suggests to go near the walls with the right side

of the machine as shown in fi gure 3.

A

A

B

Figure 3

P100364

Squeegee adjustment

If necessary, stop the machine and turn the squeegee balance adjusting handwheel (35) so that the rear blade - in all its length

4.

- touches the fl oor.

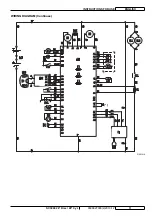

Adjustment of the detergent concentration in the solution

(For machine with EcoFlex™ system)

The system used to mix the detergent with the washing water can be activated by pressing the detergent fl ow control switch (A, Fig.

4): when the LED (B) is on, the detergent is added to the washing water.

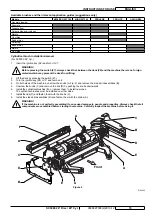

The display (C) shows the detergent concentration level in the solution as shown in the table in Figure 5.

NOTE

The detergent concentration in the solution dispensed from the system always corresponds to level 1. In order to

temporarily obtain a stronger concentration, press the EcoFlex™ switch or disable the EcoFlex™ system (see the

relevant paragraph).

EcoFlex™ function

Lift the EcoFlex™ lever (D, Fig. 4) whenever a stronger washing power is required.

When lifting the lever (D) (LED (E) fl ashing) the solution fl ow increases, the extra pressure function activates (for machines with

EcoFlex™ system) and the detergent concentration in the corresponding solution rises to the set level (moreover, if the detergent

mixing function is not activated, it activates automatically).

The original settings can be restored by lifting the lever (D) once again (LED (F) on).

NOTE

If the lever (D) is not lifted once again, the original settings are restored automatically after 60 seconds.

In order to change the actual detergent concentration, proceed as follows:

Turn off the detergent fl ow control switch (A) (the LED (B) must be OFF).

1.

Press and hold the detergent fl ow control switch (A) until the LED (B) fl ashes.

2.

Release the switch (A). Press it again shortly to go to the next level shown by the display (C) as shown in the table in Figure 4;

3.

repeat the procedure until the desired setting is reached.

Wait until the LED (B) stops fl ashing: the new level is now set.

4.

NOTE

Detergent percentage setting is stored into memory, even if the machine is turned off.

Summary of Contents for 9087266020

Page 2: ......