2

9098827000(2)2010-12

SC3000 26” Disc / 28” Cyl.

ENGLISH

INSTRUCTIONS FOR USE

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the operator with all necessary information to use the machine properly, in a safe and

autonomous way. It contains information about technical data, safety, operation, storage, maintenance, spare parts and disposal.

Before performing any procedure on the machine, the operators and qualifi ed technicians must read this Manual carefully. Contact

Advance in case of doubts concerning the interpretation of the instructions and for any further information.

TARGET

This Manual is intended for operators and technicians qualifi ed to perform the machine maintenance.

The operators must not perform procedures reserved for qualifi ed technicians. Advance will not be answerable for damages coming

from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the machine, inside an adequate case, away from liquids and other substances

that can cause damage to it.

IDENTIFICATION DATA

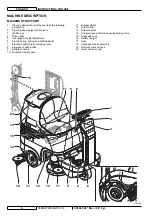

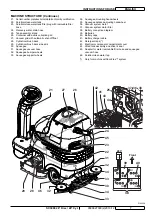

The machine serial number and model are shown on the plate (21) on the steering column.

The machine production year is written in the declaration of conformity and it is also indicated by the fi rst two fi gures of the machine

serial number.

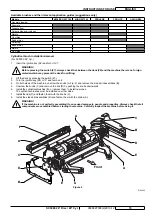

This information is useful when requiring machine spare parts. Use the following table to write down the machine identifi cation data.

MACHINE model ...............................................................................

MACHINE serial number ...................................................................

OTHER REFERENCE MANUALS

Electronic battery charger Manual (to be considered as integral part of this Manual)

–

Moreover, the following Manuals are available:

Service Manual (that can be consulted at Advance Service Centers)

–

Spare Parts List (supplied with the machine)

–

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be performed by qualifi ed personnel or by Advance Service

Centers. Only original spare parts and accessories must be used.

Contact Advance for service or to order spare parts and accessories, specifying the machine model and serial number.

CHANGES AND IMPROVEMENTS

Advance constantly improves its products and reserves the right to make changes and improvements at its discretion without being

obliged to apply such benefi ts to the machines that were previously sold.

Any change and/or addition of accessory must be approved and performed by Advance.

OPERATION CAPABILITIES

This scrubber-dryer is used to clean (scrubbing and drying) smooth and solid fl oors, in civil or industrial environment, under safe

operation conditions by a qualifi ed operator.

The scrubber-dryer cannot be used for moquette and carpet cleaning.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to say on the driver’s seat

(17).

Summary of Contents for 9087266020

Page 2: ......