FORM NO. 56043111 - Adhancer

™

-

35

WHEEL DRIVE SYSTEM

GENERAL FUNCTIONAL OVERVIEW

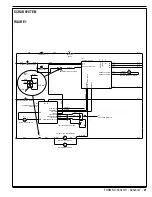

See Figures 1 and 2.

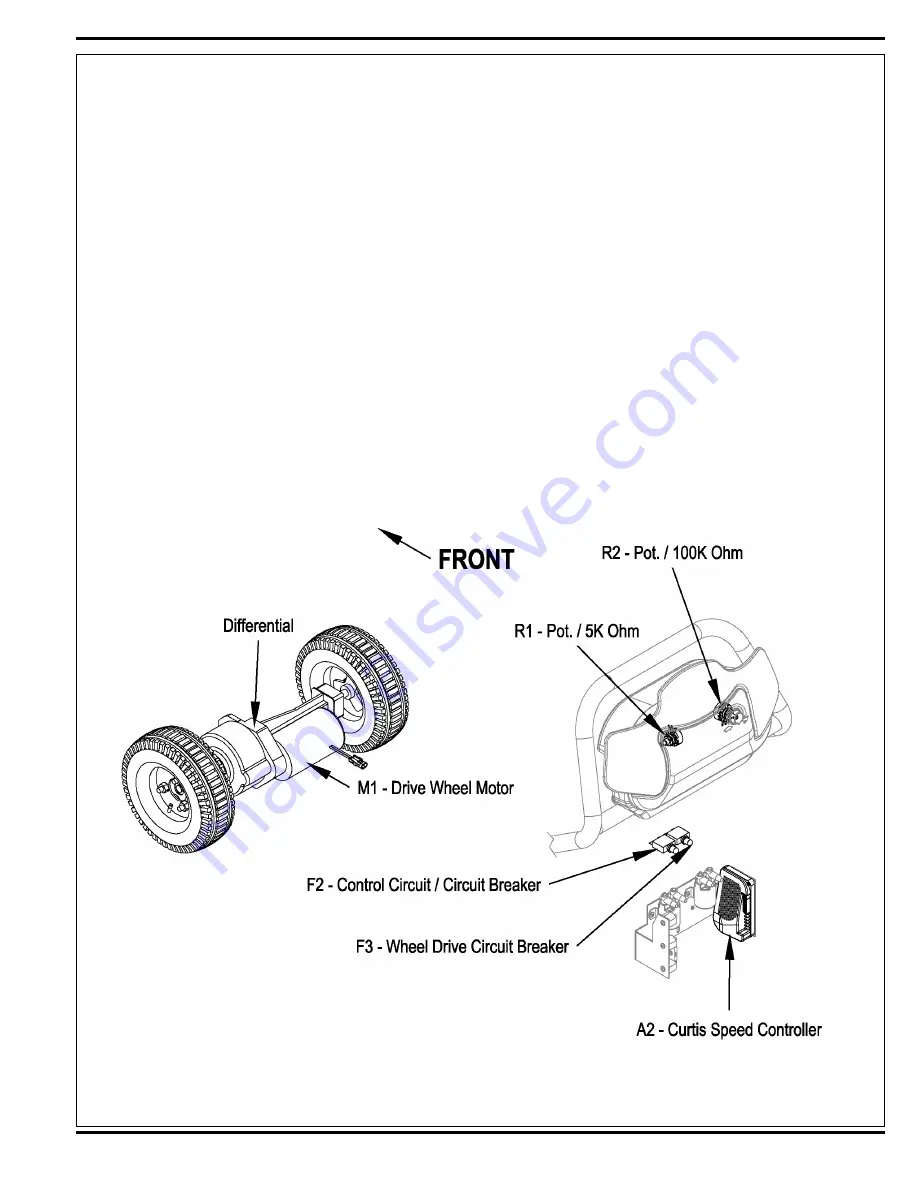

A 375-watt (.5 HP) permanent-magnet (36V) motor transaxle (M1) is used for the wheel drive on all machines. A Curtis PMC solid-state

speed controller (A2) regulates the variable speed and forward/reverse wheel drive motor functions. Location of the controller is in the rear handle housing electrical

compartment (accessible by removing the four screws securing the rear electrical panel). The potentiometer R1, mounted inside the drive paddle, inputs the

machine operator’s throttle (variable speed) and direction demands to the A2 controller. A second pot, R2 (knob adjusted), is located on the outside of the paddle

cover and controls the machine’s maximum transport and scrub speeds.

Drive Motor System Function

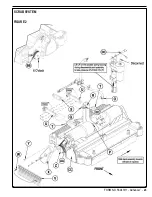

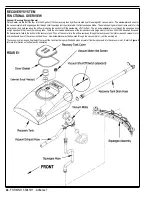

See Figures 2 and 3.

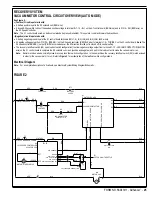

With the key switch S3 closed, the BRN wire inputs 36V to the A2 speed controller (Pin 5-KSI) to make its internal control circuits operational

(powering it up). The F3 circuit breaker (30-amp) supplies the positive load circuit voltage input to the B+ controller terminal (WHT/YEL wire). The black wire from

the battery negative standoff supplies the (NEG.) input to the B- controller terminal.

Moving the 5K Ohm R1 pot off its centered balanced neutral setting of approximately 2500 Ohms activates the operator input to the speed control. Forward or

reverse movement of the drive paddle rotates the pot shaft and the pot’s variable resistance values are changed, which generates the internal voltage signals (0-5

volts) needed for the controller’s output operation. These control board voltage input signals are what energizes the forward and reverse directional relays, which

then selects the motor polarity and

fi

nal voltage level outputs at the M1 and M2 terminals.

When the operator turns the R2 speed limit Pot from min. to max. (CW) this causes an input resistance relationship change between the pot high (+) and wiper

terminals (high to low Ohms) thus increasing the maximum wheel motor operating speed range. Turning the knob (CCW) increases the resistance and the motor

speed range is reduced.

FIGURE 1

Summary of Contents for Adhancer 56316001(W32-C)

Page 1: ...7 08 FORM NO 56043111 SERVICE MANUAL Models 56316000 W28 C 56316001 W32 C Adhancer...

Page 2: ......

Page 7: ...FORM NO 56043111 Adhancer 5 TECHNICAL SPECIFICATIONS...

Page 25: ...FORM NO 56043111 Adhancer 23 SCRUB SYSTEM FIGURE 2...

Page 51: ...FORM NO 56043111 Adhancer 49 FIGURE 4...

Page 53: ...FORM NO 56043111 Adhancer 51 FIGURE 5 ELECTRICAL SYSTEM...

Page 59: ...FORM NO 56043111 Adhancer 57 FIGURE 6 ELECTRICAL SYSTEM...

Page 68: ......

Page 74: ......