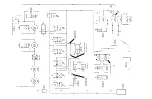

HYDRAULIC SYSTEM

TigerCat, Hydro-Retriever 4500

Service Manual

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

GENERAL INFORMATION

The hydraulic system is powered by the hydraulic pump assembly, mounted directly on the engine bell hous-

ing. The pump assembly consists of 2 pumps bolted together. The front (closest to the engine) portion of the

assembly is the propulsion pump - a variable displacement piston pump, controlled by the drive pedal in the

operator’s compartment. The propulsion pump drives the wheel motor only.

The the accessory pump is mounted on the back of the propulsion pump. This pump delivers 11.7 gallons per

minute (GPM) to power all other hydraulic motors and cylinders on the machine. A priority flow divider, built

into the accessory pump, assures a constant flow of 3 GPM to the power steering box.

Hydraulic motors turn the main sweeping broom, the side broom(s) and the scrub brushes. Hydraulic cylin-

ders are used to raise and lower the squeegee, scrub brushes, hopper, side broom(s) and to open the hopper

dump door. The hydraulic motors and cylinders are controlled by electric solenoid valves. The valves and

their functions are covered later in this section.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

HYDRAULIC OIL & FILTER MAINTENANCE

The oil level in the hydraulic oil tank should be checked every 15 hours of operation. The tank is located under

the operator’s seat. The oil in the tank should just cover the bottom of the screen in the tank filler neck. If the

oil level is low, add 10W-30 motor oil (API service SF-SF/CC or SF/CD).

The hydraulic oil filter should be replaced after the first 30 hours of operation. After the first change, the filter

should be replaced only when the red “hydraulic filter” indicator light (on the dashboard) glows.

Every 1500 hours of operation, a sample of the hydraulic oil should be tested for contamination. If the oil is not

contaminated, it does not have to be changed. If the oil is contaminated, follow the instructions in this section

under

Hydraulic Oil Tank Drain

.

75