Repairs

A paraglider is a lifting surface of complex construction . Seams and

lines have been made with great precision . In general, therefore, an

unauthorised individual should not carry out paraglider repairs . Only

the manufacturer or an authorised Service Organisation should replace

components with identical parts, or refit complete cells .

Small repairs become exceptions to this principle . Examples could be

repairs to small tears or holes with self-adhesive Ripstop material, or re-

placing lines . In every case of repair or line change the paraglider must

be pulled up on the ground before its next flight, and visually checked .

Your paraglider is delivered with a repair kit containing self-adhesive

Ripstop . Other parts, such as lines, quicklinks, softlinks or risers can

be obtained from your ADVANCE dealer, an ADVANCE Service Center

or direct from ADVANCE . Addresses are on www .advance .ch .

Canopy Repairs

Tears up to 3 cm in length, and very small holes that do not meet a

seam, can be patched with the self-adhesive Ripstop from your repair

kit . Make sure than the patch is cut out in a round or oval shape, and

is big enough to generously overlap the damage . The similar piece of

sticky Ripstop on the inside of the repair should be of a different size .

Detailed instructions can be found on Eine detaill www .advance .ch .

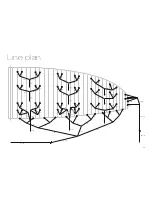

Line repairs

A damaged line must be changed, without exception . The easiest op-

tion is to go to an ADVANCE Service Centre or your ADVANCE dealer .

Alternatively you can order the specific replacement line direct from

ADVANCE or an ADVANCE dealer and fit it yourself . All the addresses

are on: www .advance .ch . Under “Service” on www .advance .ch there

are detailed instructions for identifying your line so that you can order it,

and then fit it correctly on the wing .

What to do if the leading edge gets damaged?

If a leading edge wire breaks or its seam rips the glider must be tak-

en to an ADVANCE checking facility where the wire can be replaced or

sewn back in . To guarantee a long lifespan it is important that the wing

is not allowed to fall on its leading edge after landing, otherwise the

fabric can be damaged by abrasion . But mainly there is a risk, as in all

paragliders, that the crossports could tear .

Disposal

Environmental protection plays an important role in the selection of

materials and the manufacture of an ADVANCE product . We use only

non-hazardous materials that are subjected to continuous quality and

environmental impact assessments . When your paraglider reaches the

end of its useful life in a number of years time, please remove all metal

Repairs and disposal

33

Summary of Contents for IOTA2

Page 1: ...Edition 1 12_2017 Manual...

Page 2: ......

Page 14: ...14...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 34: ...parts and dispose of the lines canopy and risers in a waste incinera tion plant 34...

Page 38: ...38...

Page 41: ...Wing parts Winglet Upper surface Cleaning velcro Ribs Lower surface Air inlets Cells 41...

Page 44: ...Bowline 44...