0160_IOM_1.2_Mar21_6

6

FIRE – 0160 MULTI-SECTION ADJUSTABLE FRAME SYSTEM FOR FLEXIBLE SUPPORTING CONSTRUCTION

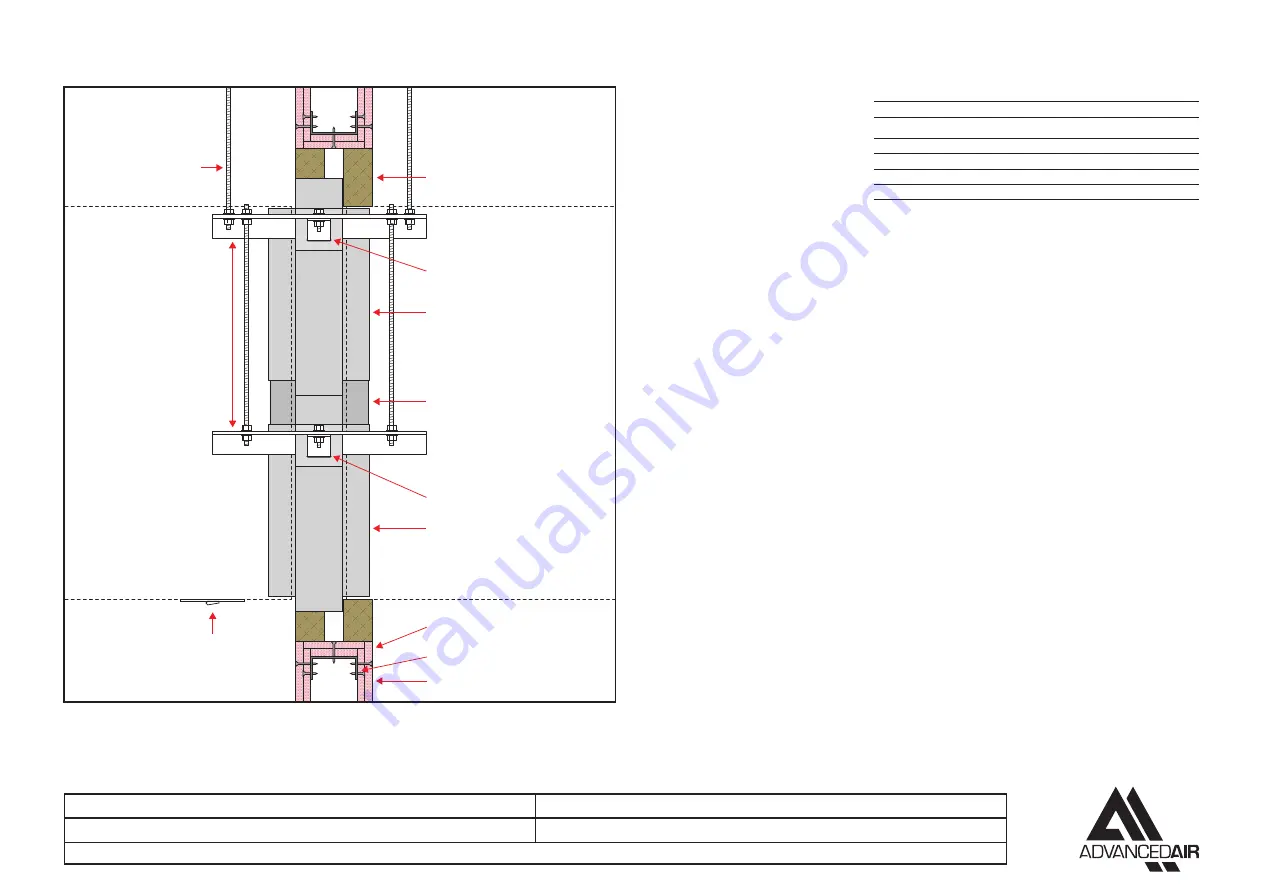

Patented Adjustable Frame System

(AFS) incorporating bracket, bracket

slot, and Z-piece

(Patent No: GB2557865)

0160 Series fire damper

AFS bracket, bracket slot,

and Z-piece

M10 drop rods

AFS rails

Access door for

inspection / damper reset

15mm thick gypsum boards

Two hour rated flexible supporting

construction to BS EN 1363-1:2020

Steel stud depth – 71 to 100mm

0160 Series fire damper

Spigot infills

Fire batt

Installation sequence

4

The drywall will consist of two layers of 15mm plasterboard each side of steel studwork with an

optional mineral wool insulation. The opening will be a letterbox construction with overlapping layers

of plasterboard with an opening clearance around the damper casing in line with the above table.

5

Two M10 drop rods per fire damper shall be fitted on both sides of the drywall. These should be

securely installed in line with the manufacturer’s fixing instructions in a position to match the AFS rail.

6

The drop rods should have a nut screwed on for clamping the rail from above. These rods will be

secured to the two top AFS rails.

7

Slide the AFS rails in all the brackets and insert the “Z” piece into the bracket slot pushing it up against

the underside of the rail. Insert the 8mm bolt from above into the slot through the “Z” piece fitting the

nut until tight to secure the rail.

8

Additional drop rods should then be passed through the top and bottom rails and fully tightened.

9

The damper should be mounted centrally in the opening flush with the wall on one side. The anchored

drop rods are to slide through the top rails and nuts are screwed on to take the support. The damper must

then be levelled and when in the correct position the nut above the rail should be tightened against the rail.

10

The galvanised mild steel ductwork connecting to the damper spigots must overlap by up to 40mm,

leaving a minimum 10mm clearance for any duct expansion in a fire situation.

11

The galvanised mild steel ductwork connections must be sealed with an approved galvanised mild

steel ductwork sealer and fixed with low resistance fixings such as aluminium rivets that will melt at

high temperature allowing the duct to break away without effecting the integrity of the installation.

12

The connecting galvanised mild steel ductwork must be independently supported within one metre of

the connections and have been installed in accordance with DW144.

13

The gap between the damper and the wall opening will need filling with two layers of 50mm thick

140kg/m3 fire batt cut to an interference fit and pushed in to place. All cut edges must be sealed with

a firebatt sealant to BS EN 13501-2. A fire rated intumescent mastic (to BS EN 13501-2) shall be applied

to each joint.

14

An access door should be fitted on the access side of the damper to enable the resetting of the

damper blades.

15

When the damper installation has been completed checks should be made to ensure the AFS rails are

secured to the damper and there is no movement, operation of the damper should be checked.

16

Complete DW145 Fire Damper Certificate.

Preparation

1

Ensure that the damper is kept

in a clean dry environment and

that there is no damage to the

damper.

2

Remove all the packaging and

transit ties before installation.

3

Work out the opening size to be

cut using the adjacent table.

Nom. duct width

Opening width min.

Opening width max.

1001-2,000mm

Nom. duct +194mm

Nom. duct +350mm

Nom. duct height Opening height min. Opening height max.

1001-1146mm

Nom. duct +150mm

Nom. duct +400mm

1147-1521mm

Nom. duct +175mm

Nom. duct +425mm

1552-1996mm

Nom. duct +200mm

Nom. duct +450mm

1997-2000mm

Nom. duct +225mm

Nom. duct +475mm

PRODUCT

0160 MULTISECTION W/AFS

APPLICATION

FLEXIBLE SUPPORTING CONSTRUCTION

CLASSIFICATION REPORT NO.

TBA

CLASSIFICATION

E120 (VE I

O)

TESTED INSTALLATION METHOD SHOWN. DIFFERING INSTALLATION METHODS TO THIS MUST BE APPROVED BY THE BUILDING CONTROL AUTHORITY (BCA) BEFORE PROCEEDING.

While we have tested a damper 2,000 x 2,000mm, larger sizes can be supplied but the installation will need to be checked by a

competent structural engineer as stated in the Extended Fields of Application BS EN 15882-2:2015. With all larger sizes there should

be a risk assessment carried out and a full method statement documented to ensure the correct lifting gear and safety precautions

are put in place prior to the installation being carried out.