E

2

T QUASAR Flare Monitors Operation Manual

Operating the M8100FM-EXP

•

39

b.

Verify that noise amplification has not returned. If the noise has returned, proceed

to step 5.

c.

If noise has not returned, the procedure is completed. (Proceed to 6.1.8, Relay

Contacts.)

5.

Reduce the delay time and repeat the above procedure.

a.

If noise amplification continues, repeat the setup adjustment procedures starting at

Section 6.1.4, System Gain/Climate Compensation

.

b.

If problems persist, contact the factory for further technical assistance. (Refer to

Section 1.5

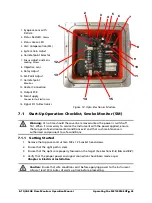

6.1.8

Relay Contacts

Check the relay contacts at the instrument’s Terminal Output board. N.O. and N.C. contacts are

both available simultaneously. Verify that the desired polarity is obtained during an alarm

condition.

Note:

Make note of the contact position when the instrument power is interrupted

or shut-off. The relay is energized when the green LED is lit. It is not energized during

an alarm or power loss.

6.1.9

Delay Adjust

The Delay Adjust (Item 9) can be configured from 2 seconds (completely counterclockwise) to

approximately 2 minutes (completely clockwise). The Delay Pot postpones the Alarm condition

once the set-point value is exceeded. This can prevent false alarms from temporary loss of signal

due to wind.

6.1.10

Milliamp Output (+mA / -mA)

Check the milliamp output signal at the instrument’s Terminal Output board. The signal should

be approximately 4mA when the flame is present and the analog meter reads full-scale. The

signal should read approximately 20mA when flame is lost, with analog meter under .35 of

scale.

Milliamp checks must be accomplished with a Milliamp meter placed in series with the control

room loop or parallel across the mA+ and mA- terminals when no other connections are on the

terminals.

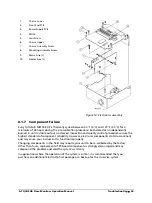

1.

Replace the top cover and the sixteen M8 x 1.25 socket head screws, torque to 30in/lbs.

2.

Supply positive air flow and pressure to the air connections.

3.

Verify that the temperature of the QUASAR M8100-EXP housing will not exceed 120 ° F

(50 °C). If cooling is required, refer to

Chapter 3, Mechanical Installation

.

6.2

Considerations for the Flare Monitor (FM)

In the case where it is not possible to eliminate the Pilot flame completely from the instrument’s

field of view, it is necessary to verify that a “Flame-out” alarm will occur as expected. It is

recommended that you complete the following procedure to confirm proper operation. Be sure

to complete the start-up checklist procedure first. Refer to

Section 6.1

1.

Ensure that the Pilot flame is present and that the Flare is in the condition where the

operator wishes to see an Alarm from the instrument.