MNALAZIN-02

25

Integration in the Servo System / Mounting

Soldering

Soldering an AZ board directly to a PCB provides added support against mechanical

shocks and vibration. It is recommended to solder AZ drives to a PCB following the industry

standard for Acceptability of Electronic Assemblies IPC‐A‐610D. Use solder with no‐clean flux.

AZ drives can be soldered by any of the following methods:

•

wave soldering

•

hand soldering

•

selective wave soldering

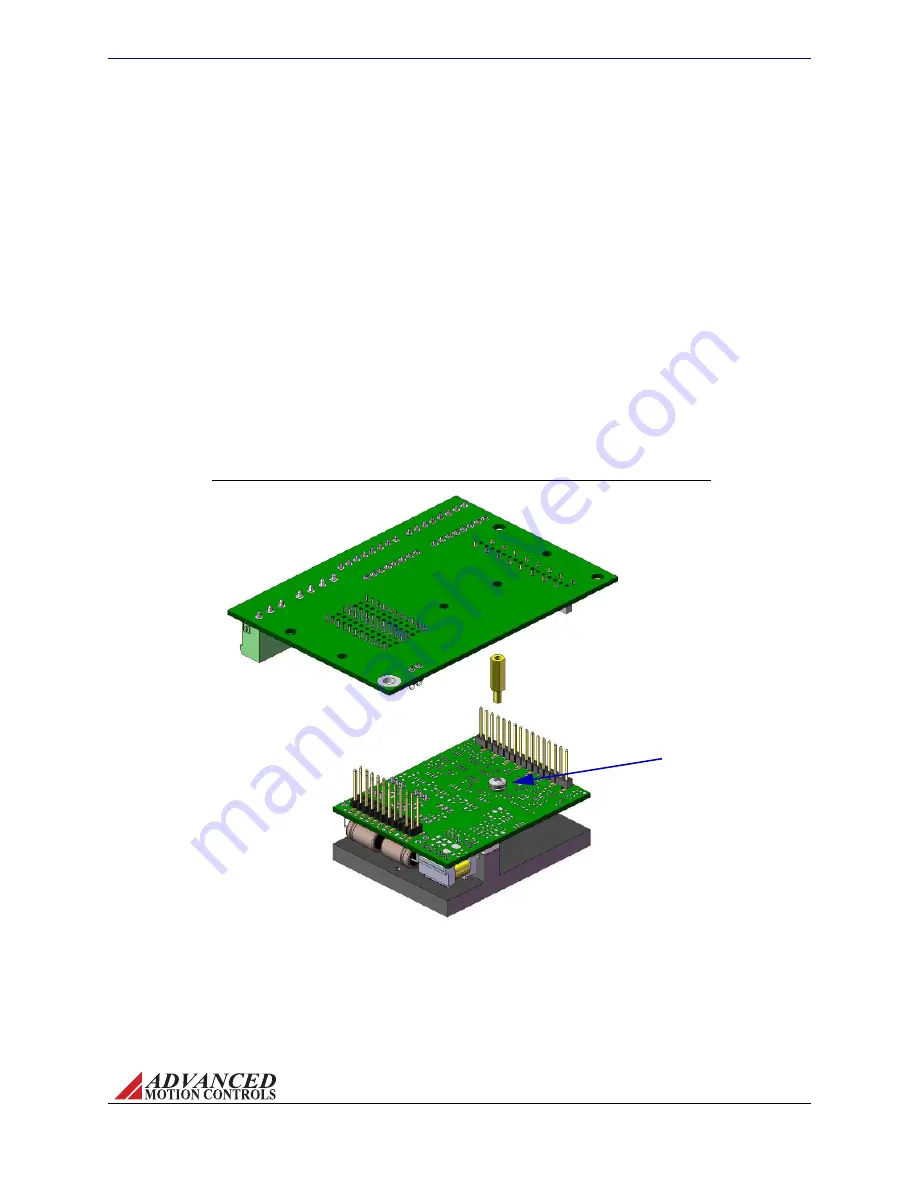

FIGURE 3.5

Remove drive mounting screw,

and replace with spacer*. Use

the removed drive mounting

screw to secure mounting card

to drive from the bottom of the

mounting card through the

spacer after drive has been

inserted in mounting card

socket connectors.

*Spacer not included with AZ drive or

mounting card. Spacer shown is

standard 3/16" hex 4/40 thread,

male/female, 7/16" length.

Drive Mounting Screw

AZ20 Screw Mount Diagram

To clean the PCB and drive after soldering, it is recommended to gently apply isopropyl alcohol

or a cleaning agent with a soft‐bristled brush. Use care not to apply downward pressure, but

rather lightly brush the PCB and drive. Do not immerse the drive in a cleaning agent.

Screw Mounting

For added stability and support, AZ drives can be mounted with screws in

tandem with one of the options above.

Figure 3.5

shows how an AZ20 drive can be mounted to

the MC1XAZ01 mounting card using a spacer. See

“Physical Dimensions” on page 39

and/or

the specific drive’s datasheet for exact screw locations and dimensions.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com