Page 12

ES/ESH-LT209_10152019

Single Stage Unitary Range

INSTALLATION

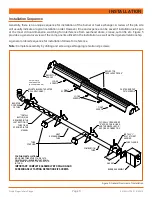

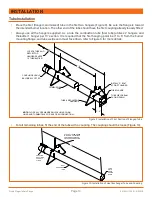

Tube Installation

•

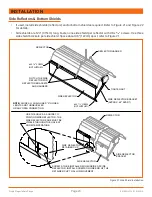

Place the first (flanged, aluminized) tube in the first two hangers (Figure 9). Be sure the flange is toward

the intended burner location. The other end of the tube should have the first coupling already loosely fitted.

•

Always use all the hangers supplied. As a rule the combustion tube (first tube) utilizes 2 hangers and

thereafter 1 hanger per 10’ section. It is required that the first hanging point be 3” to 6" from the burner

mounting flange, and tube weld seam must face down, refer to Figure 9 for more details.

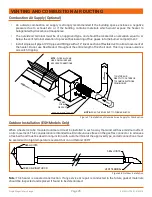

Figure 9: Installation of First Section of Flanged Tube

COUPLING SHOULD

BE LOOSELY FITTED

10'

8' - 9'

10'

3" - 6"

COMBUSTION

TUBE

TUBE & REFLECTOR

HANGERS

LOCATE TUBE AND

REFLECTOR

HANGERS EVERY

10' THEREAFTER.

NOTE:

CLOSE ALL OPEN-ENDED QUICK LINKS, CHAIN

LINKS,AND TURNBUCKLES OR ANY OPEN CONNECTION.

INSTALL "J" BOLT

AT FIRST HANGER

TUBE FLANGE

TUBE WELD SEAM

FACING DOWN

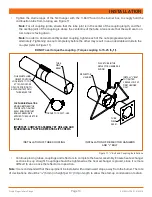

•

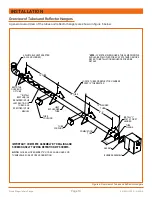

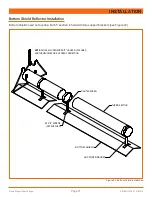

For all remaining tubes, fit the end of the tube with a coupling. The coupling should be loose (Figure 10).

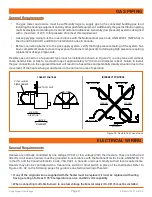

Figure 10: Installation of Heat Exchanger Tube and Coupling

10'

COUPLING

SHOULD BE

LOOSELY

FITTED

HEAT

EXCHANGER

TUBE

CLOSE ALL OPEN ENDED

"S" HOOKS, CHAIN LINKS,

AND TURNBUCKLES OR

ANY OPEN CONNECTION.

TUBE

WELD

SEAM

FACING

DOWN

Summary of Contents for ES/ESH Series

Page 2: ......