ElectraCOOL

LA550 Chiller

For Information Call

1 800-250-2920

electracool.com

One Tara Boulevard

Nashua, NH 03062 USA

international Inquiries (603) 888-2467

rev 7/03

16

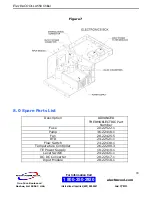

7.1 Coolant Draining Procedure

1.

Remove plug from drain cock (see figure 1 and John Guest insert for details)

2.

Connect ¼” OD hose to push on connector on drain cock and place other end

in a suitable container

3.

Remove fill port plug

4.

Open drain-cock

5.

Let drain for 10 minutes

6.

Remove filter access panel

7.

Remove screw holding the filter support strap

8.

Loosen and remove the filter housing (it will be full of fluid) pour fluid into

the container

7.2 Fuse Replacement

1.

Ensure chiller power is turned off and chiller main power is unplugged

2.

Remove chiller from the rack

3.

Remove the 9 screws holding the top cover and remove the cover

4.

Remove the perforated electronics enclosure cover

5.

Remove fuse with a fuse puller

6.

Replace fuse

7.

Reinstall the perforated cover.

8.

Close top cover and fasten with the 9 screws removed in step 3 (use Loctite

242)

9.

Reinstall chiller and check operation

7.3 Filter Replacement Procedure

1.

Drain system as per draining procedure

2.

Remove filter access panel (see figure 1)

3.

Remove screw holding the pump support strap

4.

Loosen and remove the filter housing (it will be full of fluid) pour fluid into a

suitable container.

5.

Inspect the filter for particulate and clean if necessary.

6.

Reinstall filter and housing

7.

Reattach filter support strap

8.

Close filter access panel

9.

Follow fill procedure to refill the system