(7)

Plow Assembly & Adjustments

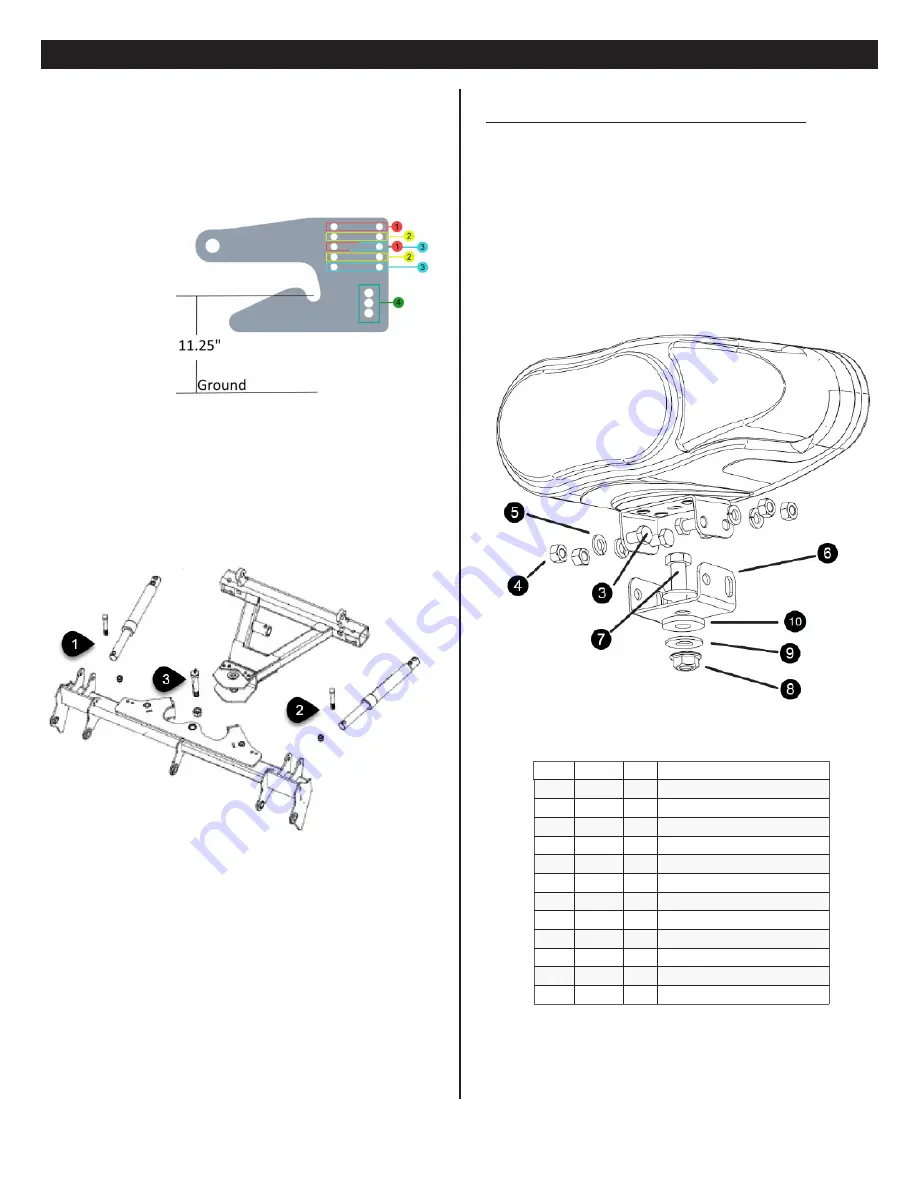

Nite Saber LED Lights

Nite Saber LED Lights

See seperate Nite Saber LED instructions for further information.

Mount the lights as shown below.

Connect both male ends from the snow plow light to the female ends on the

Plow Side Harness. Ensure all wiring harnesses are secured against the lift

frame.

Check snow plow lights and blinkers to ensure proper operation. If operating

in reverse (i.e. driver side blinking instead of passenger side), reverse the har-

ness connections.

Note: All electrical connections should have both ends coated with a dielectric

grease (Meyer Part # 15632) prior to final installation. This will ensure a good

connection and help in preventing corrosion.

Nite Saber LED Parts List

Item

Part

QTY Description

-

23067

1

Nite Saber LED Kit

-

23066

1

Passenger Side LED

-

23065

1

Driver Side LED

-

08126

1

Hardware Bag

3

-----

8

• Hex Bolt 3/8” x 3/4”, SS

4

-----

8

• Hex Nut 3/8”, SS

5

-----

8

• Lock Washer 3/8”, SS

6

-----

2

• Metal Bracket, Bottom

7

-----

2

• Bolt 1/2”- 13 x 1 1/12”, SS

8

-----

2

• Hex Lock Nut 1/2” - 13, SS

9

-----

4

• Flat Washer 1/2”, SS

10

-----

2

• Neoprene Grommet 1/2”

Adjustable Clevis

Adjustable Clevis

The 14700 adjustable clevis

The 14700 adjustable clevis is now standard with all Standard Operating Sys-

tem black iron packages. The 14700 Adjustable Clevis cannot be used with any

EZ+ Operating System plow model.

The 14700 Clevis offers 3 levels of adjustability for a height difference of +/- 1.5

inches. To use the adjustability feature, mounting the clevis using two sets of

applicable holes. Use one of the bottom 3 holes to secure to the clevis to the

mount.

Level 1 = Rows 1 and 3

Level 2 = Rows 2 and 4

Level 3 = Rows 3 and 5

The clevis requires a height of 11.25” off the ground in order for the plow to sit

level.

Pivot Bar

Pivot Bar

The Pivot Bar will need to be bolted to the A-Frame and Angling Cylinders. Cut

any ties that are securing the cylinders to the crate prior to removing black

iron from the crate. The Angling Cylinders will already be connected to the Lift

Frame. Hardware to attach the Pivot Bar to the Angling Cylinders and A-Frame

can be found in the Accessory Box.

Summary of Contents for MEYER DIAMOND EDGE

Page 3: ...2 Black Iron Parts List...