EMA

Alkatrészlista

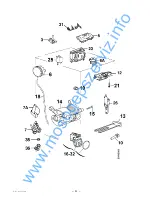

Háztartási mosógépek

2510

PNC

ELC

Márkanév

Modell

Piac

913761321

01

AEG

LAV41270

CZ - HU - PL

Felültöltős mosógépek

Distriparts Deutschland GmbH

Publikáció szám

Muggenhofer Straße 135

599513201

D-90429 Nürnberg

2007/11/27

Germany

FFH

Fax +49 (0)911 323 1022

© Electrolux

www.mosogepszerviz.info

Summary of Contents for EMW2000

Page 2: ...1 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 4: ...3 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 6: ...5 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 8: ...7 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 10: ...9 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 17: ...PROGRAMM SELECTOR 16 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 18: ...CYCLE 17 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 19: ...CYCLE 18 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 20: ...CYCLE 19 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 21: ...WIRING DIAGRAM 20 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 22: ...ELEMENTARY DIAGRAM 21 Electrolux w w w m o s o g e p s z e r v i z i n f o...

Page 24: ...w w w m o s o g e p s z e r v i z i n f o...

Page 26: ...w w w m o s o g e p s z e r v i z i n f o...

Page 43: ...KAPCSOL SI ALAPRAJZ AC MOTOR w w w m o s o g e p s z e r v i z i n f o...

Page 44: ...KAPCSOL SI ALAPRAJZ w w w m o s o g e p s z e r v i z i n f o...

Page 95: ...4 HV844 N 12 01 R B 599 51 30 44 EN D DIMENSIONS w w w m o s o g e p s z e r v i z i n f o...

Page 143: ...PROGRAMM SELECTOR w w w m o s o g e p s z e r v i z i n f o...

Page 144: ...CYCLE w w w m o s o g e p s z e r v i z i n f o...

Page 145: ...CYCLE w w w m o s o g e p s z e r v i z i n f o...

Page 146: ...CYCLE w w w m o s o g e p s z e r v i z i n f o...

Page 147: ...WIRING DIAGRAM w w w m o s o g e p s z e r v i z i n f o...

Page 148: ...ELEMENTARY DIAGRAM w w w m o s o g e p s z e r v i z i n f o...