12

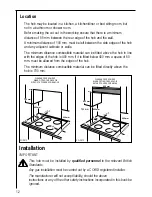

Location

The hob may be located in a kitchen, a kitchen/diner or bed sitting room, but

not in a bathroom or shower room.

Before making the cut out in the worktop ensure that there is a minimum

distance of 55 mm. between the rear edge of the hob and the wall.

A minimum distance of 100 mm. must be left between the side edges of the hob

and any adjacent cabinets or walls.

The minimum distance combustible material can be fitted above the hob in line

with the edges of the hob is 400 mm. If it is fitted below 400 mm. a space of 50

mm. must be allowed from the edges of the hob.

The minimum distance combustible material can be fitted directly above the

hob is 700 mm.

650 mm

400 mm

400 mm

100 mm

50 mm

50 mm

55 mm

600 mm

700 mm

400 mm

100 mm

400 mm

50 mm

55 mm

50 mm

CLEARANCES REQUIRED

WHEN FITTING THE GAS HOB

WITHOUT A COOKER HOOD ABOVE

CLEARANCES REQUIRED

WHEN FITTING THE GAS HOB

WITH A COOKER HOOD ABOVE

FO 0813

FO 0812

Installation

IMPORTANT

This hob must be installed by

qualified personnel

to the relevant British

Standards.

Any gas installation must be carried out by a CORGI registered installer.

The manufacturer will not accept liability, should the above

instructions or any of the other safety instructions incorporated in this book be

ignored.

700 mm