Summary of Contents for AFNDA2565

Page 1: ...AFNDA2565 ANGLED FINISH NAILER ORIGINAL INSTRUCTIONS ...

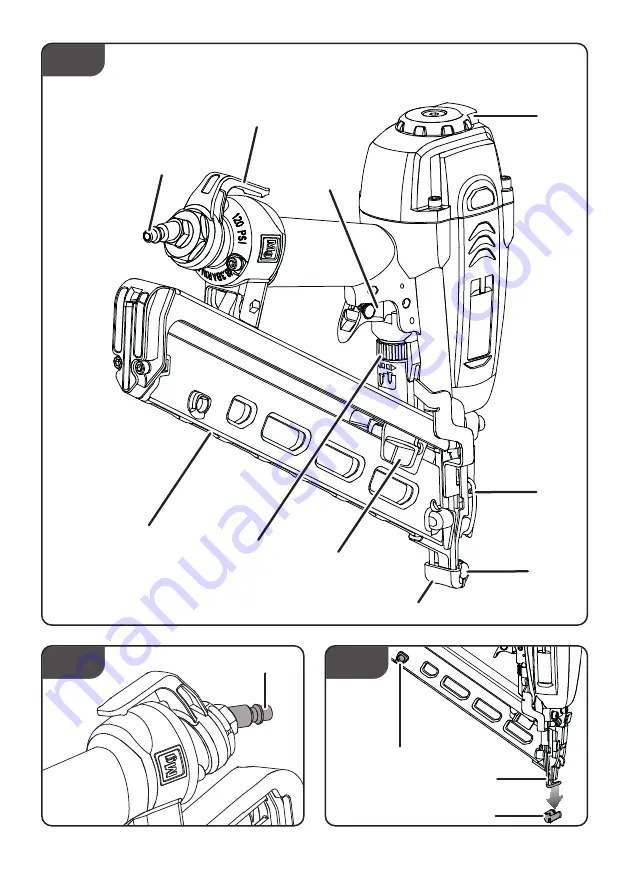

Page 2: ...2 1 4 10 9 8 7 5 6 3 4 9 11 12 Fig 1 Fig 2 Fig 3 ...

Page 3: ...1 2 15 16 17 1 13 7 14 5 2 8 4 Fig 4 Fig 6 Fig 5 Fig 7 Fig 8 Fig 9 ...

Page 4: ...19 6 10 21 7 20 18 1 2 Fig 10 Fig 12 Fig 11 ...

Page 15: ......

Page 16: ......