Deutsch

19

English

GB

b) When blade is binding, or when interrupting a cut for

any reason, release the trigger and hold the saw motionless

in the material until the blade comes to a complete stop.

Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or kickback may

occur.

Investigate and take corrective actions to eliminate the cause

of blade binding.

c) When restarting a saw in the workpiece, centre the saw

blade in the kerf so that the saw teeth are not engaged into

the material.

If a saw blade binds, it may walk up or kickback from

the workpiece as the saw is restarted.

d) Support large panels to minimise the risk of blade

pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under the panel on both sides,

near the line of cut and near the edge of the panel.

e) Do not use dull or damaged blades.

Unsharpened or im-

properly set blades produce narrow kerf causing excessive friction,

blade binding and kickback.

f) Blade depth and bevel adjusting locking levers must be

tight and secure before making the cut.

If blade adjustment

shifts while cutting, it may cause binding and kickback.

g) Use extra caution when sawing into existing walls or

other blind areas.

The protruding blade may cut objects that can

cause kickback.

Lower guard function

a) Check the lower guard for proper closing before each use. Do

not operate the saw if the lower guard does not move freely and

close instantly. Never clamp or tie the lower guard into the open

position.

If the saw is accidentally dropped, the lower guard may

be bent. Raise the lower guard with the retracting handle and make

sure it moves freely and does not touch the blade or any other part,

in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the

guard and the spring are not operating properly, they must

be serviced before use.

Lower guard may operate sluggishly due

to damaged parts, gummy deposits, or a build-up of debris.

c) The lower guard may be retracted manually only for

special cuts such as „plunge cuts“ and „compound cuts“.

Raise the lower guard by the retracting handle and as soon

as the blade enters the material, the lower guard must be

released.

For all other sawing, the lower guard should operate

automatically.

d) Always observe that the lower guard is covering the

blade before placing the saw down on bench or floor.

An

unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the

blade to stop after switch is released.

Additional Safety and Working Instructions

Wear ear protectors. Exposure to noise can cause hearing loss.

Use protective equipment. Always wear safety glasses when

working with the machine. The use of protective clothing is re-

commended, such as dust mask, protective gloves, sturdy non-slip

footwear, helmet and ear defenders.

The dust produced when using this tool may be harmful to health.

Do not inhale the dust. Use a dust absorption system and wear a

suitable dust protection mask. Remove deposited dust thoroughly,

e.g. with a vacuum cleaner.

Do not use saw blades not corresponding to the key data given in

these instructions for use.

It is necessary to select a saw blade which is suitable for the

material being cut.

Use only woodworking blades specified in this manual, which

comply with EN 847-1.

The rated speed of the accessory must be at least equal to the

maximum speed marked on the power tool.

Do not fix the on/off switch in the „on“ position when using the saw

hand-held.

Do not use abrasion discs in this machine!

WORKING INSTRUCTIONS

Adapt the feed speed to avoid overheating the blade tips.

SPECIFIED CONDITIONS OF USE

This electronic circular saw can cut lengthways and mitre accura-

tely in wood.

MAINS CONNECTION

Connect only to single-phase AC system voltage as indicated on

the rating plate. It is also possible to connect to sockets without an

earthing contact as the design conforms to safety class II.

Appliances used at many different locations including wet room

and open air must be connected via a residual current device (FI,

RCD, PRCD) of 30mA or less.

Always disconnect the plug from the socket before carrying out any

work on the machine.

Keep mains lead clear from working range of the machine. Always

lead the cable away behind you.

Before use check machine, cable, and plug for any damages or

material fatigue. Repairs should only be carried out by authorised

Service Agents.

MAINTENANCE

Always disconnect the plug from the socket before carrying out any

work on the machine.

If the replacement of the supply cord is necessary, this has to be

done by the manufacturer or his agent in order to avoid a safety

hazard.

Be sure to disconnect the tool from the power supply before

attaching or removing the saw blade.

Clean tool and guarding system with dry cloth.

Certain cleaning agents and solvents are harmful to plastics and

other insulated parts.

Keep the apparatus handle clean, dry and free of spilt oil or grease.

Check the function of guards.

Regular maintenance and cleaning provide for a long service life

and safe handling.

The ventilation slots of the machine must be kept clear at all times.

Remove dust regularly. Remove the sawdust which has accummu-

lated inside the saw in order to avoid the risk of fire.

Summary of Contents for KS12-1

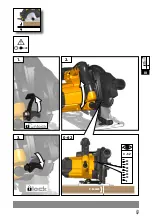

Page 5: ...3 1 2 2 1 I ...

Page 6: ...4 3 EN 847 1 4 I ...

Page 7: ...5 5 6 TEST 2 2 x 1 I ...

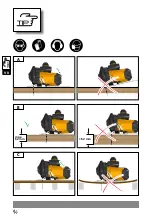

Page 11: ...9 1 3 0 62 mm 0 62 2 III 0 62 40 30 20 10 0 50 60 ...

Page 12: ...10 3 1 4 2 IV 50 45 40 30 10 20 0 50 45 40 30 10 20 0 0 51 5 0 10 20 30 40 51 5 ...

Page 14: ...12 START 2 1 1 2 3 4 STOP VI 45 0 ...

Page 15: ...13 VI 2 5 2 4 0 0 1 3 2 1 START 6 1 STOP ...

Page 16: ...14 VII max 62 mm 62 mm A B C ...

Page 18: ...16 VIII 5 3 90 6 4 ...