Setting up and connection instructions

49

Water Inflow

A pressure hose 1.5m in length is supplied.

If a longer inflow hose is required, only a VDE-approved, complete set

of hoses with fitted hose screw connections offered by our Customer

Service is permissible.

– Sets of hoses in lengths of 2.2m, 3.5m and 5m are available for

washing machines without Aqua-Control.

– Sets of hoses in lengths of 2.0m, 2.9m and 3.9m are available for

washing machines with Aqua-Control.

Attention!

Never cut into pieces in order to extend the hoses!

3

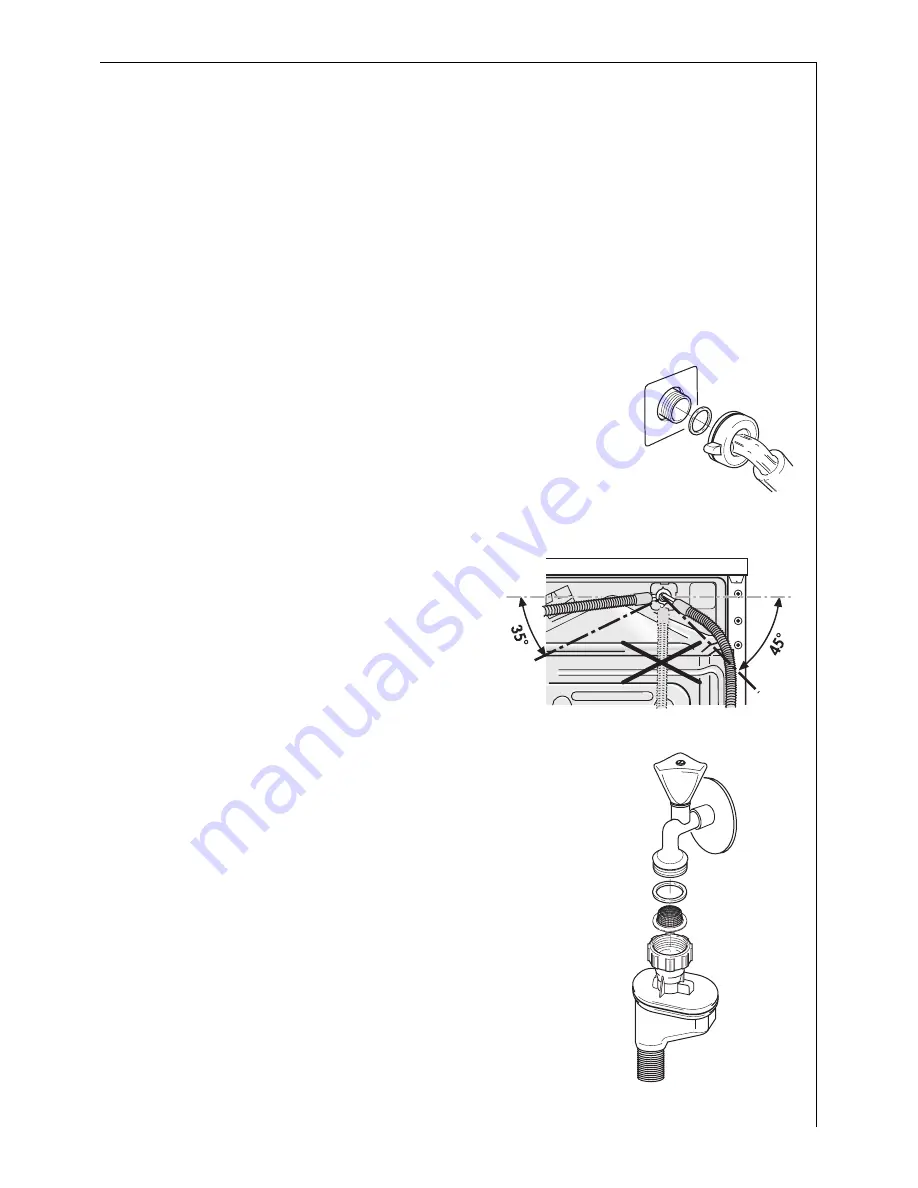

Sealing rings are supplied either in the plastic

nuts of the hose screw connection or in the

enclosed pack. Do not use other seals!

0

1.

Connect the hose with the angled connection to

the machine.

Attention!

– Do not lay the supply hose

vertically downwards. Rather,

turn it to the right or left as

shown in the diagram.

– Only tighten the screw

connection manually.

2.

Connect the hose with the

straight connection to a water tap with a screw

thread of R 3/4 (inches).

Attention!

Only tighten the screw connection

manually.

3.

By slowly opening the water tap before putting

the washing machine into operation, check

whether the connection is free of leaks.

Summary of Contents for LAVAMAT 76730

Page 1: ...ÖKO LAVAMAT 76730 update The Environmentally Friendly Washing Machine User Information ...

Page 52: ...52 ...

Page 53: ...53 ...