16

16

may fall from the cutting area.

Disconnect the product from the mains supply or remove battery

pack before carrying out any maintenance or cleaning the product.

Only connect to the mains supply when the product is switched off.

Never reach into the area near the blade unless the blade has

completely stopped.

Before use, thoroughly check the product, cable and plug for any

damage or material fatigue. Repairs to the whole product should only

be carried out by an authorised service centre.

Always use the guards on the product. Do not use the product if the

guards are not in place and working correctly.

The lower blade guard should only open when the blade is lowered

to the workpiece and must always be able to move freely and close

automatically.

Always fix and use extension bar holders for workpiece support

during operation.

Never alter of modify the product or its function. Your safety may be

compromised.

Do not use saw blades which are cracked, damaged or deformed.

Do not use saw blades made of high-speed steel.

Only use blades that are sharp. Replace dull blades.

Always use blades with correct size and shape of arbor holes.

Blades that do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

Use only woodworking blades specified in this manual, which comply

with EN 847-1.

Do not use any flanges, washers and nuts to secure the saw blade

other than those supplied or indicated in the instruction manual.

It is necessary to select a saw blade which is suitable for the material

being cut. Never use the product to cut materials other than those

specified in the intended use section in this manual.

It is important to avoid overheating the blade and melting the plastic

workpiece when cutting.

It is essential to adhere to the maximum speed specified on the saw

blade, only use saw blade that are marked with a speed equal or

higher than the speed marked on the tool.

Replace the table insert when worn or damaged.

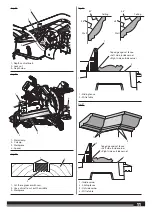

Before work, make a dummy cut without the motor turned on so the

position of the blade, operation of the guards with respect to other

machine parts, and workpiece may be checked.

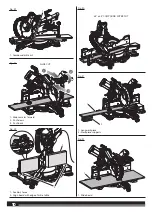

When performing mitre, bevel or compound mitre cuts, adjust or

remove the sliding fence to ensure the correct clearance from the

blade.

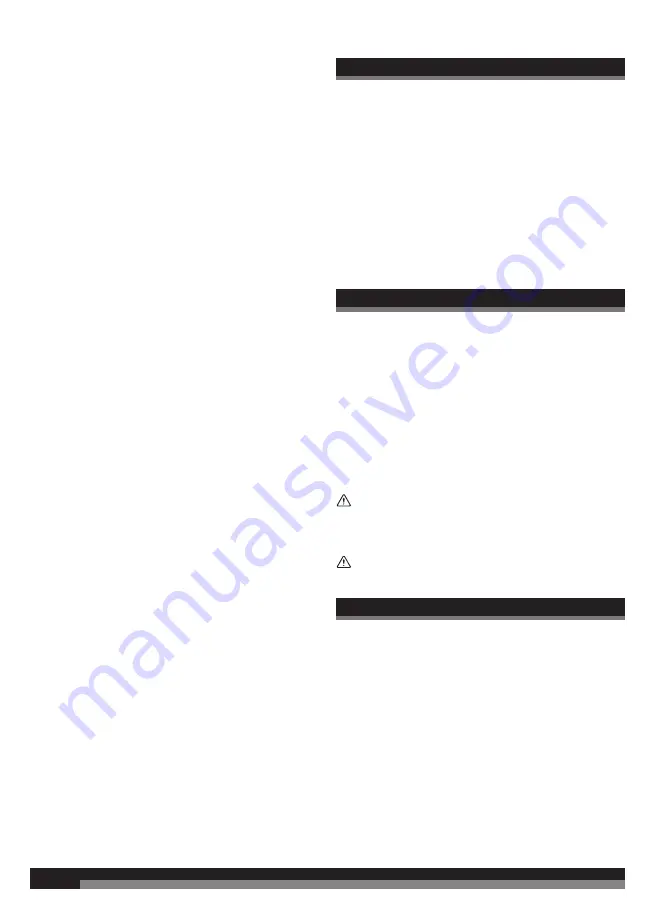

The bracket stop must always be engaged when transporting the

product.

Keep the floor area free of loose materials, such as chips and cut-offs.

Refrain from removing any cut-offs or other parts of the workpiece

from the cutting area whilst the product is running and the saw head

is not in the rest position.

Long workpieces must be adequately supported. The working area

of the saw includes the whole extent of the workpiece. The operator

should secure this area from accidental contact from other persons or

objects which may move the workpiece during operation.

The dust produced when using the product may be harmful to health.

Use a dust suction system and wear a suitable dust protection mask.

Remove deposited dust thoroughly with a vacuum cleaner.

Do not replace the LED with a different type. Any repairs must only be

carried out by the manufacturer or authorised service agent.

It is recommended that the product always be supplied via a residual

current device having a rated residual current of 30mA or less.

When using the product, voltage fluctuations may affect other

electrical products or lighting on the same power circuit. Connect the

product to a power source with an impedance equal to 0.

299

:

to

minimize voltage fluctuations. Contact your electric power supplier for

further clarification.

SPECIFIED CONDITIONS OF USE

The mitre saw is intended for sawing solid and bonded wood,

materials similar to wood, with or without glued veneer and plastics.

The mitre saw is intended to be used only by adult operators who

have read the instruction manual and understand the risks and

hazards.

The mitre saw is designed to be fixed at the base to a solid bench

top or a dedicated work stand. If the base is not securely fixed, the

whole machine may move during cutting operations, which increases

the possibility of serious personal injury.

The mitre saw is designed to make bevel and mitre cuts. The

capacities for the various cuts are provided in the sliding compact

mitre saw product specifications in this manual.

The mitre saw is to be used in dry conditions, with excellent ambient

lighting and adequate ventilation.

The mitre saw is intended for consumer use and should only be used

as described above and is not intended for any other purpose.

RESIDUAL RISKS

Even when the slide compound mitre saw is used as prescribed, it is

still impossible to completely eliminate certain residual risk factors.

The following hazards may arise and the operator should pay special

attention to avoid the following:

Ŷ

Risk of contact with uncovered parts of the rotating saw blade.

Ŷ

Kick-back of work pieces or parts of work pieces due to improper

adjustment or handling.

Ŷ

Catapulting of faulty carbide tips from the saw blade. Wear Eye

protection at all times.

Ŷ

Damage to the respiratory system. Wear respiratory protection

masks containing filters appropriate to the materials being

worked. Ensure adequate workplace ventilation. Do not eat, drink

or smoke in the work area.

Ŷ

Damage to hearing if effective hearing protection is not worn.

WARNING!

Dust from certain paints, coatings, and materials

may cause irritation or allergic reactions. Dust from wood such as

oak, beech, MDF, and others are carcinogenic. Materials containing

asbestos should only be worked on or processed by qualified

specialist operators.

WARNING!

Injuries may be caused or aggravated by prolonged

use of a tool. When using any tool for prolonged periods, ensure you

take regular breaks.

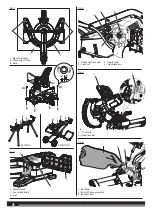

ASSEMBLY

UNPACKING

Packing list

Ŷ

Mitre saw x 1

Ŷ

Saw blade x 1

Ŷ

Dust bag x 1

Ŷ

Work clamp x 1

Ŷ

Left sliding fence x 1

Ŷ

Right sliding fence x 1

Ŷ

Operator’s manual x 1

The product requires assembly.

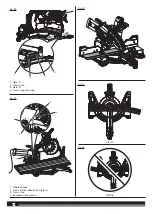

Carefully lift the saw from the carton by holding both the “D” handle

and carrying handle, and place it on a level work surface.

The product has been shipped with the saw arm secured in the down

position. To release the saw arm, push down on the top of the saw

arm, cut the tie-wrap, and pull out the head lock pin.