23

23

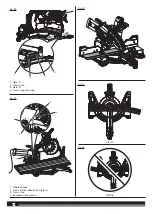

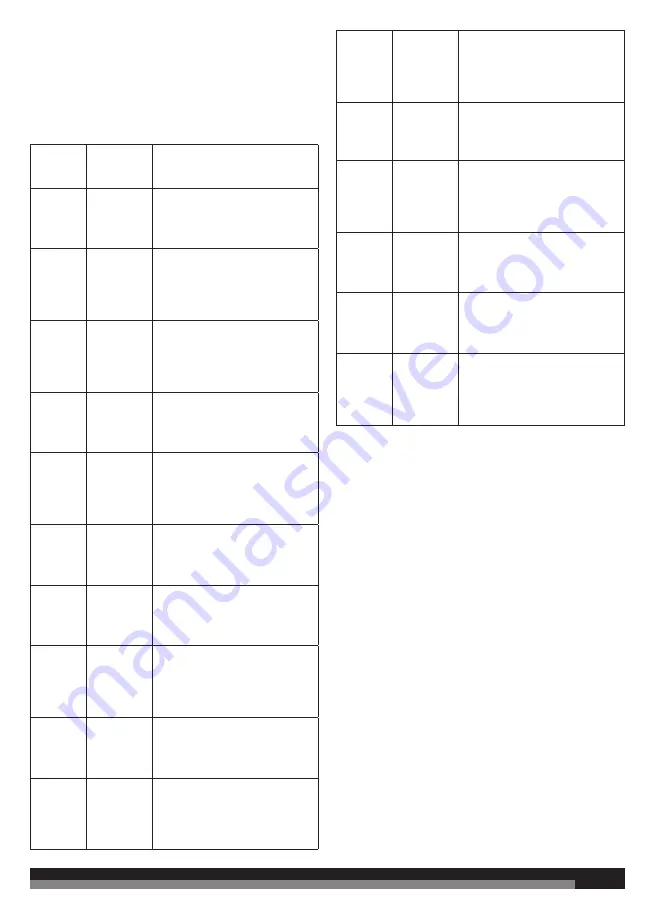

When cutting crown molding by this method the bevel angle should

be set at 33.9°. The mitre angle should be set at 31.6° either right or

left, depending on the desired cut for the application. See the chart

below for correct angle settings and correct positioning of crown

molding on mitre table.

The settings in the chart below can be used for cutting crown molding

with 52° and 38° angles or 45° and 45° angles. The crown molding is

placed flat on the mitre table using the compound features of the

product.

Type of

crown

molding

Bevel angle

type of cut

Setting

38

o

33.9

o

(Left)

Left side of inside corner

1. Top edge of molding against fence

2. Mitre table set right 31.6

o

3. Save left end of cut

38

o

33.9

o

(Left)

Right side of inside corner

1. Bottom edge of molding against

fence

2. Mitre table set left 31.6

o

3. Save left end of cut

38

o

33.9

o

(Left)

Left side of outside corner

1. Bottom edge of molding against

fence

2. Mitre table set left 31.6

o

3. Save right end of cut

38

o

33.9

o

(Left)

Right side of outside corner

1. Top edge of molding against fence

2. Mitre table set right 31.6

o

3. Save right end of cut

38

o

33.9

o

(Right)

Left side of inside corner

1. Bottom edge of molding against

fence

2. Mitre table set right 31.6

o

3. Save right end of cut

38

o

33.9

o

(Right)

Right side of inside corner

1. Top edge of molding against fence

2. Mitre table set left 31.6

o

3. Save right end of cut

38

o

33.9

o

(Right)

Left side of outside corner

1. Top edge of molding against fence

2. Mitre table set left 31.6

o

3. Save left end of cut

38

o

33.9

o

(Right)

Right side of outside corner

1. Bottom edge of molding against

fence

2. Mitre table set right 31.6

o

3. Save left end of cut

45

o

30

o

(Left)

Left side of inside corner

1. Top edge of molding against fence

2. Mitre table set right 35.3

o

3. Save left end of cut

45

o

30

o

(Left)

Right side of inside corner

1. Bottom edge of molding against

fence

2. Mitre table set left 35.3

o

3. Save left end of cut

45

o

30

o

(Left)

Left side of outside corner

1. Bottom edge of molding against

fence

2. Mitre table set left 35.3

o

3. Save right end of cut

45

o

30

o

(Left)

Right side of outside corner

1. Top edge of molding against fence

2. Mitre table set right 35.3

o

3. Save right end of cut

45

o

30

o

(Right)

Left side of inside corner

1. Bottom edge of molding against

fence

2. Mitre table set right 35.3

o

3. Save right end of cut

45

o

30

o

(Right)

Right side of inside corner

1. Top edge of molding against fence

2. Mitre table set left 35.3

o

3. Save right end of cut

45

o

30

o

(Right)

Left side of outside corner

1. Top edge of molding against fence

2. Mitre table set left 35.3

o

3. Save left end of cut

45

o

30

o

(Right)

Right side of outside corner

1. Bottom edge of molding against

fence

2. Mitre table set right 35.3

o

3. Save left end of cut

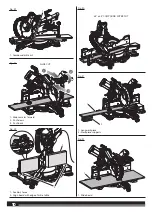

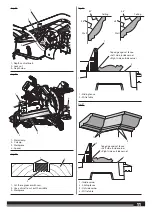

CUTTING NESTED CROWN MOLDING USING CROWN STOPS

(Crown stops not included)

See figure 38.

Crown stops may be purchased as an accessory to this saw for use in

cutting crown molding in a nested position and should be installed on

both the right and left side.

To attach the crown stops to the extension table:

Ŷ

Position a crown stop on the right extension table.

Ŷ

Insert the threaded crown stop lock knob through the long slot in

the crown stop and into Hole A as shown, but do not fully tighten

to allow for adjustment of the crown stop.

Ŷ

Set the top of the piece of crown molding on the table. Position

the spring angles so that the bottom angle is flat on the table and

the top angle is flush against the mitre fence.

Ŷ

Tighten the lock knob securely before making the cut.

NOTE

: Hole B is used for extended mitre cuts when the rotating

extension table is in the farthest outboard position.

Ŷ

Repeat steps for the left side.

CROWN AND BASEBOARD SETTING LEVER

See figure 39.

The crown and baseboard setting lever is helpful when making mitre

cuts up to 45° for tall crown molding and vertical baseboard.

Use the crown setting for tall crown molding of 120 mm and taller.

NOTE

: For cutting crown molding less than 120 mm tall, slide the saw

head to the rear most position with the crown and baseboard setting

lever in the down position.

To position for tall crown molding:

Ŷ

Unplug the saw.

Ŷ

Loosen the slide lock knob and pull the saw head forward.

Ŷ

Flip the crown and baseboard setting lever up.