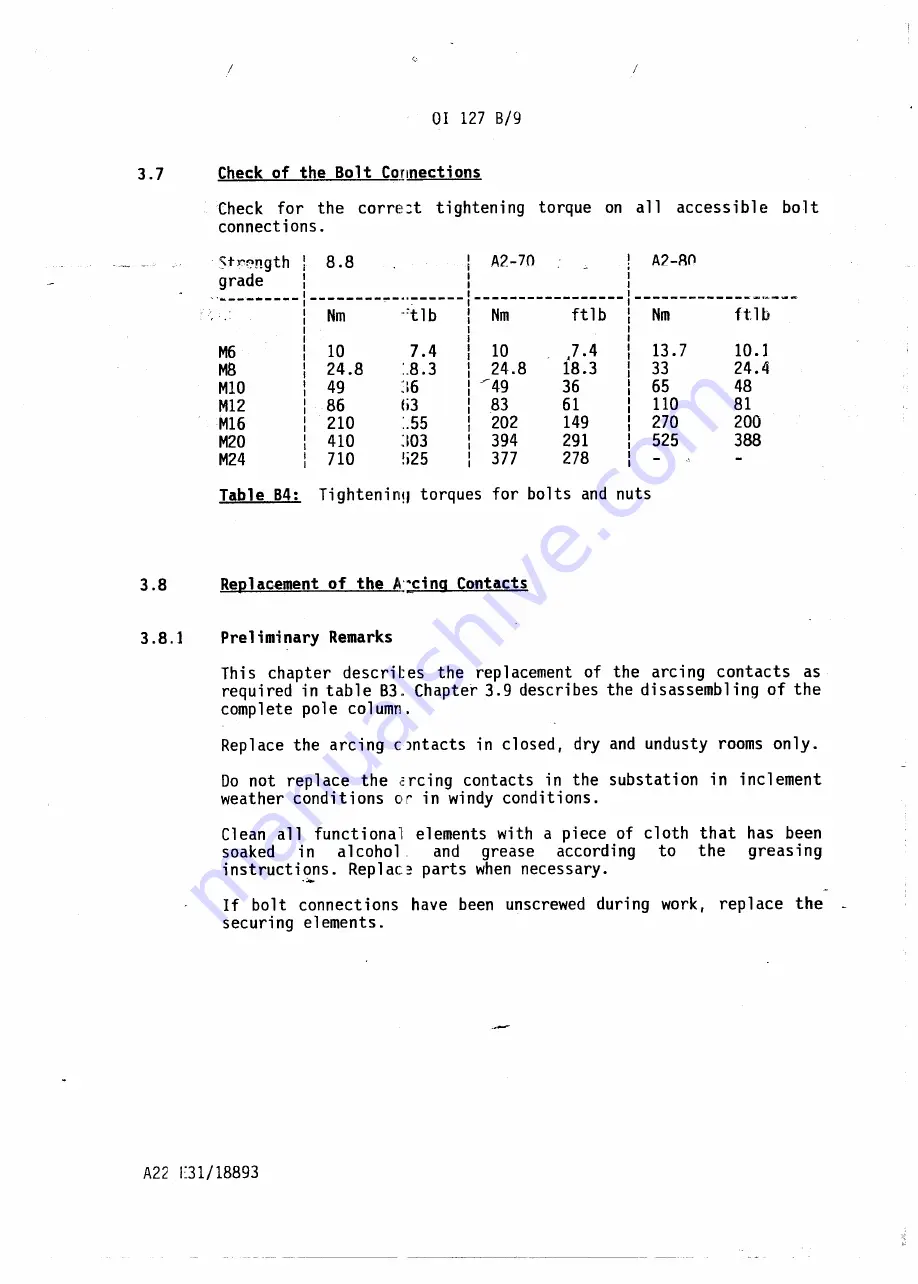

Check

for

the

corre:t

tightening

torque

on all

accessible

bolt

connections.

5

t

Y'f.'ngth

I

8.8

.A2-70

!

A2-80

I

.

grade

I

I

I

~

.'---'_.----

--------.,.-··:------1-----------------:

--------------.~-~-

Nm

··:tlb

I

Nm

ftlb

I

Nm

ftlb

I

I

I

I

i

I

M6

10

7.4

I

10

).4

I

13.7

10 .1

I

I

M8

24.8

:.8.3

I

24.8

18.3

I

33

24.4

I

I

MIO

49

]6

: -""49

36

I

65

48

I

M12

86

li3

I

83

61

I

110

81

I

I

M16

210

:.55

I

202

149

I

270

200

I

I

M20

410

]03

I

394

291

I

525

388

I

I

M24

710

!i25

I

377

278

I

I

I

Table

84:

Tighteninq

torques

for

bolts

and nuts

This

chapter

descril:es

the

replacement

of

the

arcing

contacts

as

required

in table

83. Chapter

3.9 describes

the disassembling

of the

complete

pole

column.

Replace

the

arcing

CJntacts

in closed,

dry and undusty

rooms only.

Do not

replace

the

I:rcing

contacts

in the

substation

in

inclement

weather

conditions

or in windy conditions.

Cl ean

all

funct i ona'l

elements

with

a pi ece of cloth

that

has

been

soaked

in

a 1coho 1.

and

grease

accord i ng

to

the

greas i ng

instructi.<:ns.

Replac~

parts

when necessary.

If

bolt

connections

have

been

unscrewed

during

work,

replace

the

securing

elements.

Summary of Contents for SF6

Page 21: ...Fig 83 Exploded view of tle spring operating mechanism ...

Page 31: ...SF 1377 0 SF 1377 d SF 1377 0 SF 1377 0 SF 1377 _ 0 SF 1377 d SF 1377 0 SF 1377 0 ...

Page 32: ...SF 1377 c rUlUb m m I SF 1377 c J i SF 1377 SF 137 b 0 SF 1377 SF 1377 0 b ...

Page 33: ...BeruLub FK 33 Fig B8 Points of lubrication at the interrupter unit and at thE arcing contacts ...

Page 34: ...SF 1377 bl SF 1377 bl SF 1377 II 1 _ _ _ __ L i SF 1377 bl SF 1377 cl SF 1377 bl SF 1377 bl ...

Page 35: ...1 CLtl _ l1oLykote BR2 pLus l 0 ...

Page 38: ...2 7 17 2 7 18 2 7 16 2 7 02 2 7 18 2 7 03 2 7 01 2 7 06 2 7 11 2 7 07 2 7 22 ...