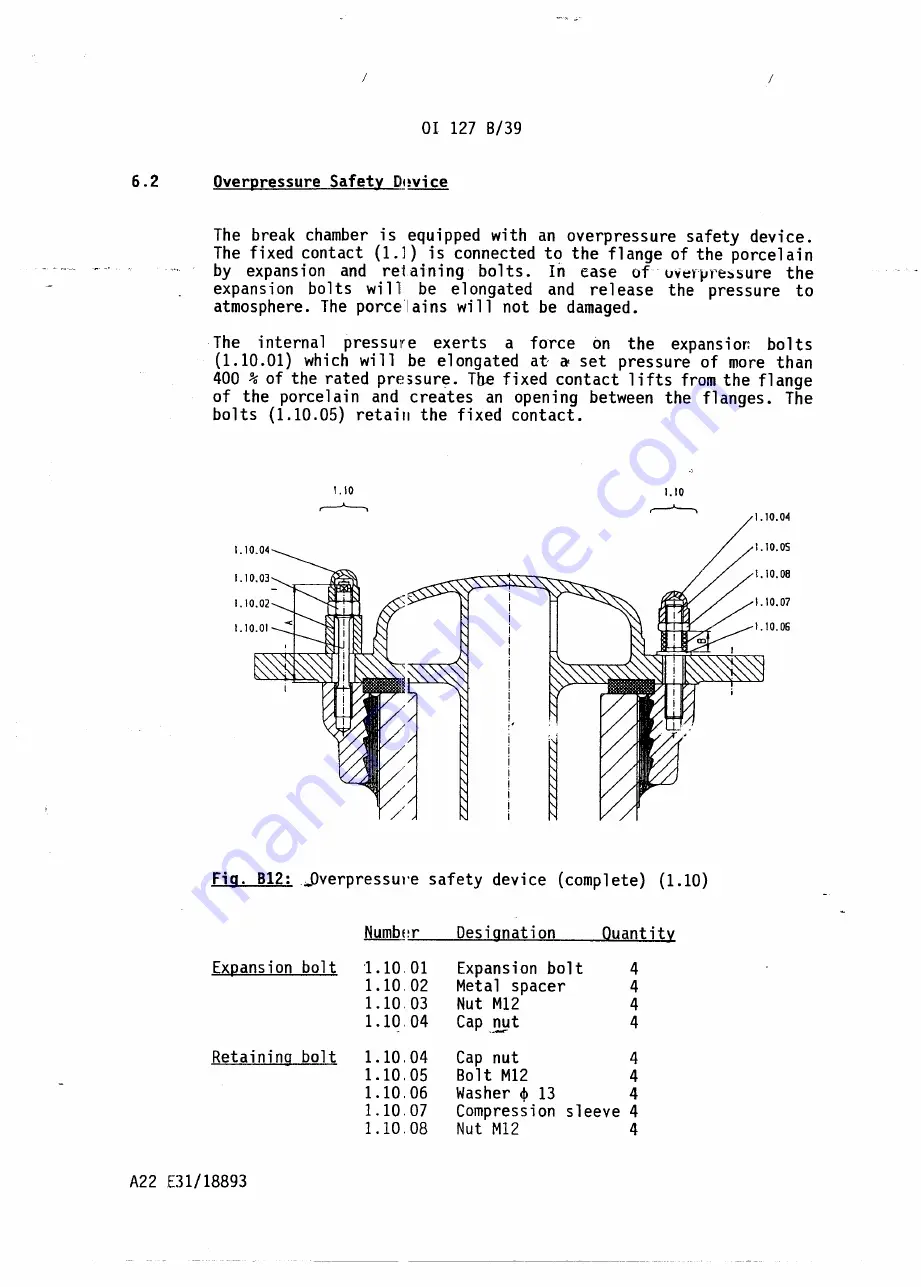

The break

chamber

is

equipped

with

an overpressure

safety

device.

The fixed

contact

(1.1)

is connected

t~ the

flange

of the porcelain

by

expansion

and

retaining

bolts.

In

ease

of

uveqJressure

the

expans i on bolts

wi 11, be

elongated

and

re 1ease

the

pressure

to

atmosphere.

The porce"1 ai ns wi 11 not be damaged.

The

internal

pressure

exerts

a

force

on

the

expansion

bolts

(1.10.01)

which will

be elongated

at

~ set

pressure

of more than

400 % of the rated

pressure.

The fixed

contact

1ifts

from the flange

of

the

porcelain

and creates

an opening

between

the

flanges.

The

bolts

(1.10.05)

retaill

the

fixed

contact.

1.10

,...--'----..

Numb.!~r

Designation

Quantity

Expans i on bolt

1.10,01

Expans i on bolt

4

1.10,02

Metal

spacer

4

1.10,03

Nut M12

4

1.1Q,04

Cap ,,'llJt

4

Retaining

bolt

1.10,04

Cap nut

4

1.10,05

Bolt

M12

4

1.10,06

Washer

<!>

13

4

1.10,07

Compression

sleeve

4

1.10" 08

Nut M12

4

Summary of Contents for SF6

Page 21: ...Fig 83 Exploded view of tle spring operating mechanism ...

Page 31: ...SF 1377 0 SF 1377 d SF 1377 0 SF 1377 0 SF 1377 _ 0 SF 1377 d SF 1377 0 SF 1377 0 ...

Page 32: ...SF 1377 c rUlUb m m I SF 1377 c J i SF 1377 SF 137 b 0 SF 1377 SF 1377 0 b ...

Page 33: ...BeruLub FK 33 Fig B8 Points of lubrication at the interrupter unit and at thE arcing contacts ...

Page 34: ...SF 1377 bl SF 1377 bl SF 1377 II 1 _ _ _ __ L i SF 1377 bl SF 1377 cl SF 1377 bl SF 1377 bl ...

Page 35: ...1 CLtl _ l1oLykote BR2 pLus l 0 ...

Page 38: ...2 7 17 2 7 18 2 7 16 2 7 02 2 7 18 2 7 03 2 7 01 2 7 06 2 7 11 2 7 07 2 7 22 ...