16

16

17

17

Tel. no. 1300 234 797

Australia

Techtronic Industries N.Z. Limited

PO Box 12-806

Penrose AUCKLAND 1642

Tel. no. 0800 234 797

New Zealand

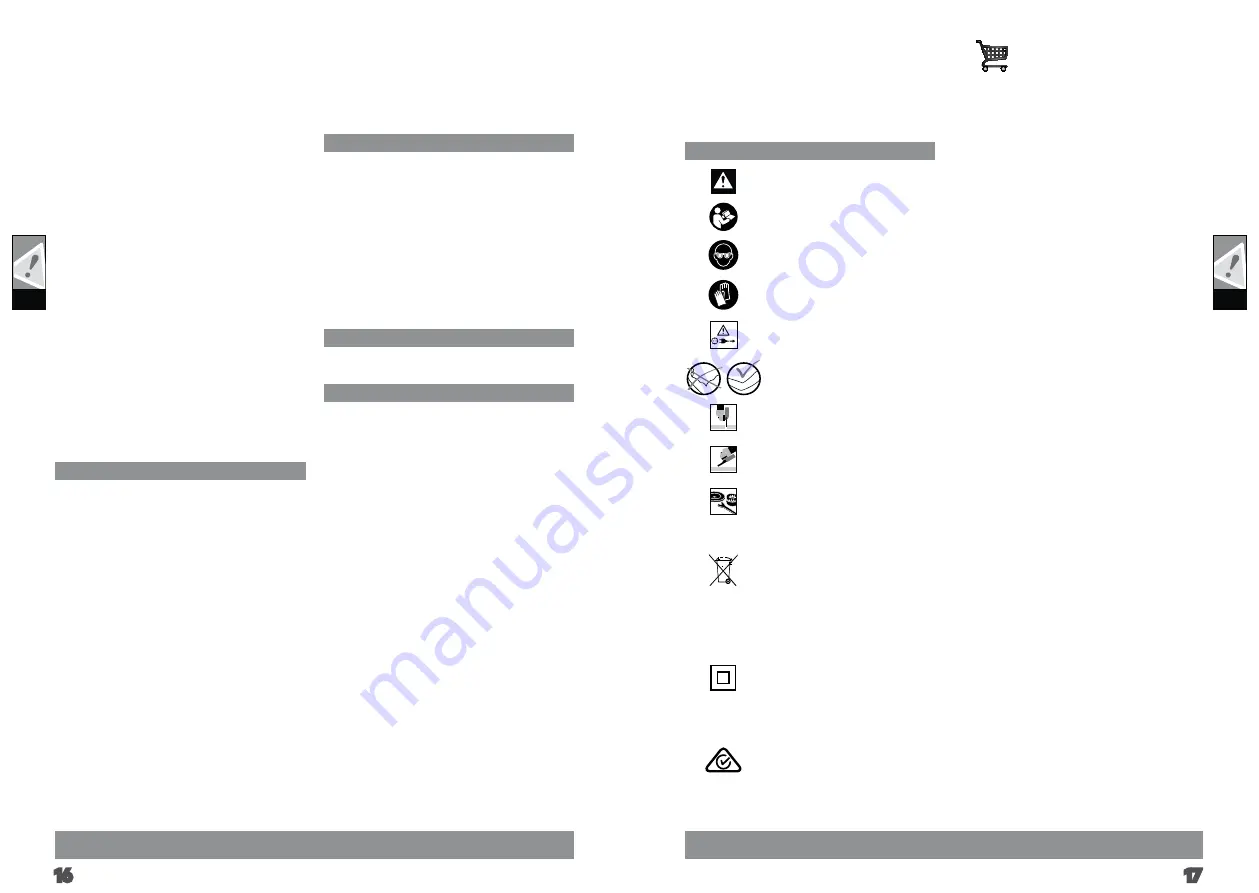

SYMBOLS

CAUTION! WARNING! DANGER!

Please read the instructions carefully

before starting the machine.

Always wear goggles when using the

machine.

Wear gloves!

Always disconnect the plug from the

socket before carrying out any work

on the machine.

Do not use force.

Only for cutting work.

Only for grinding.

Accessory - Not included in standard

equipment, available as an accessory.

Do not dispose of electric tools

together with household waste

material. Electric tools and electronic

equipment that have reached

the end of their life must be

collected separately and returned

to an environmentally compatible

recycling facility.

Class II tool. Tool in which protection

against electric shock does not rely

on basic insulation only, but in which

additional safety precautions, such

as double insulation or reinforced

insulation, are provided. There

being no provision for protective

earthing or reliance upon installation

conditions.

Regulatory Compliance Mark (RCM).

Product meets applicable regulatory

requirements.

Parts or accessories sold separately

Always use the auxiliary handle.

Always use the protecting cap when roughing-down

and separating.

Immediately switch off the machine in case of

considerable vibrations or if other malfunctions occur.

Check the machine in order to find the cause.

Always use and store the grinding disks according to

the manufacturer’s instructions.

When grinding metal, flying sparks are produced. Take

care that no persons are endangered. Because of the

danger of fire, no combustible materials should be

located in the vicinity (spark flight zone). Do not use

dust extraction machine.

Due care should be taken that no sparks or sanding

dust flying from the workpiece come into contact with

you.

When separating stone the guide shoe must be used!

The adjusting nut must be tightened before starting to

work with the machine.

The workpiece must be fixed if it is not heavy enough

to be steady. Never lead the workpiece to the grinding

disk with your hand.

Under extreme conditions (e.g., smooth-grinding

metals with the arbour and vulcanized fibre grinding

wheel), significant contamination can build up on the

inside of the angle grinder. For safety reasons in such

conditions, the inside should be cleaned thoroughly

of metal deposits and a motor circuitbreaker must be

connected in series. If the motor circuit-breaker trips,

the machine must be sent for repair.

RESIDUAL RISKS

Even when the product is used as prescribed, it is still

impossible to completely eliminate certain residual

risk factors. The following hazards may arise and the

operator should pay special attention to avoid the

following:

Injury caused by thrown-off particles

Metal or abrasive particles may enter the eyes and

cause severe permanent damage. Wear goggles

approved for grinding operations whenever you use

the product.

Injury caused by vibration

Limit exposure.

Injury caused by dust

Wear appropriate dust control mask with filters suitable

for protecting against particles from the material being

worked on and abrasive particles from the grinding

disc. Do not eat, drink, or smoke in the work area.

Ensure adequate ventilation.

Injury from contact with the grinding disc

The disc and workpiece will become hot during

use. Wear gloves when changing discs or touching

workpiece. Keep hands away from the grinding area at

all times. Clamp the workpiece whenever possible.

Injury caused by noise

Prolonged exposure to noise will increase the risk of

hearing damage, and the effects are cumulative. When

using power tools for any extended period of time,

wear hearing protection.

SPECIFIED CONDITIONS OF USE

The angle grinder may be used for cutting, grinding,

sanding and wire brushing a wide range of materials,

such as metal or stone. If you have any doubts, please

refer to the instructions supplied by the accessory

manufacturer.

Do not use this product in any other way as stated for

normal use.

For accessories intended to be fitted with threaded

hole wheel, ensure that the thread in the wheel is long

enough to accept the spindle length.

Use the safety guard from the accessories range when

performing cutting work.

MAINS CONNECTION

Connect only to single-phase AC system voltage as

indicated on the rating plate.

MAINTENANCE

Pop-off brushes

The motor will be automatically shut off indicating that

the carbon brushes are nearly worn out and that the

product needs servicing. The carbon brushes are not

user-serviceable. Take the product to an authorised

service centre.

The ventilation slots of the machine must be kept clear

at all times.

Do not let any metal parts enter the airing slots

-danger of short circuit!

If the power supply cord is damaged, it must be

replaced only by the manufacturer or by an authorised

service centre to avoid a safety hazard. Contact

authorised service centre.

Use only AEG accessories and AEG spare parts. Should

components need to be replaced which have not been

described, please contact one of our AEG service

agents (see our list of guarantee/service addresses).

If needed, an exploded view of the tool can be ordered.

Please state the machine type printed as well as the

10-digit No. on the label and order the drawing at your

local service agents.

If needed, an exploded view of the tool can be ordered.

Please state the machine type printed as well as the

six-digit No. on the label and order the drawing at your

local service agents or directly at:

Techtronic Industries Australia Pty Ltd

PO Box 1065

Mount Waverley VIC 3149

For Technical Review, sent on 25 July 2018