13

13

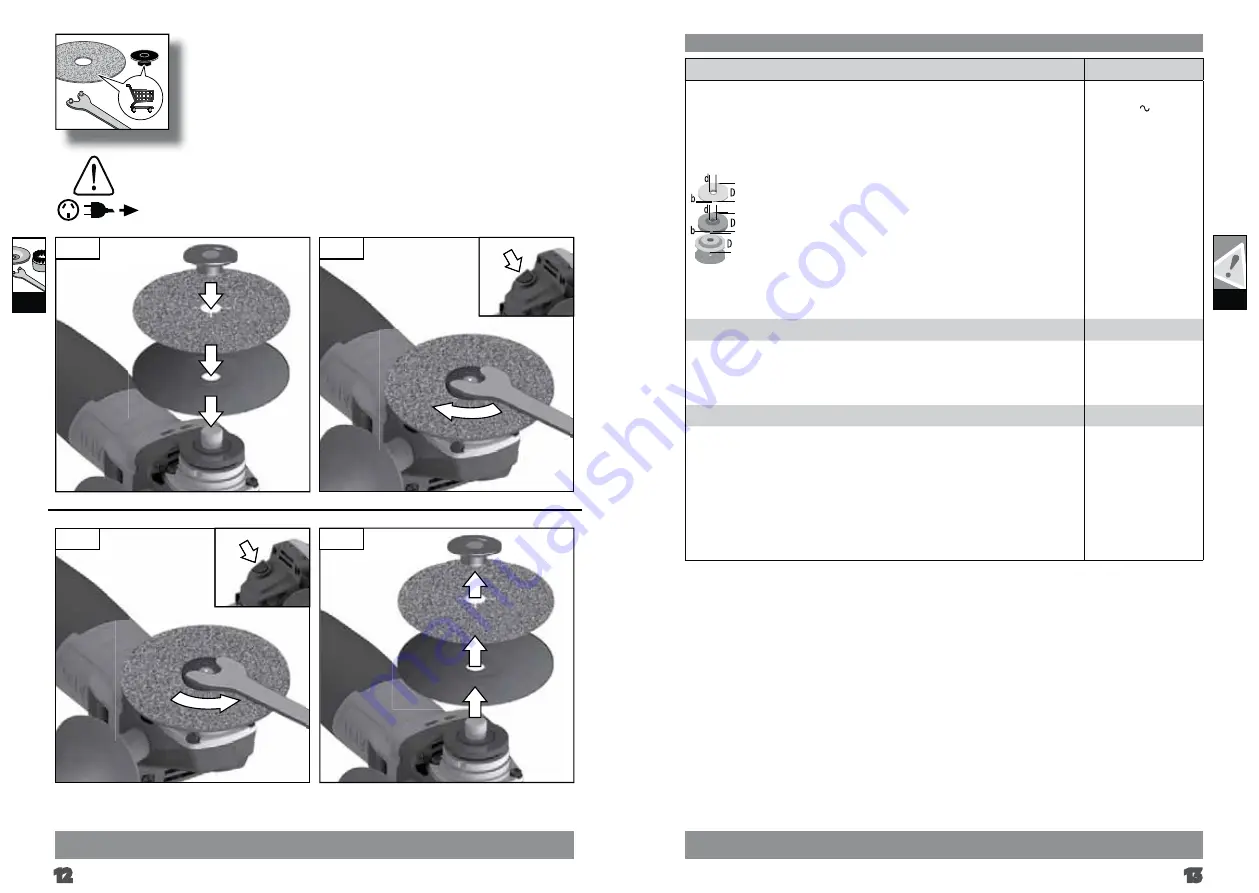

12

12

WARNING!

The vibration emission level given in this information sheet has been measured in accordance with a standardised

test given in EN 60745 and may be used to compare one tool with another. It may be used for a preliminary

assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for

different applications, with different accessories or poorly maintained, the vibration emission may differ. This may

significantly increase the exposure level over the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched

off or when it is running but not actually doing the job. This may significantly reduce the exposure level over the

total working period.

Identify additional safety measures to protect the operator from the effects of vibration such as: maintain the tool

and the accessories, keep the hands warm, organisation of work patterns.

TECHNICAL DATA

Angle Grinder

WS 72-125

Rated input

720 W

Input voltage

220-240 V 50/60 Hz

Rated speed

11000 min

-1

D= Grinding disk diameter max.

125 mm

d= Grinding disk hole diameter

22.2 mm

b= Cutting disk max. thickness

5 mm

b= Grinding disk min. thickness

6 mm

D= Grinding surface diameter max.

125 mm

Thread of work spindle

M 14

Weight according EPTA-Procedure 01/2003

2.2 kg

Abrasive products: Designation

Type

Straight cutting-off wheels not reinforced

41

Straight and depressed-centre cutting-off wheels, reinforced

41, 42

Straight and depressed-centre grinding wheels reinforced, coolie-hat wheels, flexible

wheels

1, 27, 28 & 29

Noise/Vibration Information

Measured values determined according to EN 60745. Typically, the A-weighted noise

levels of the tool are:

Sound pressure level (Uncertainty K=3dB(A))

88.5 dB(A)

Sound power level (Uncertainty K=3dB(A))w

99.5 dB(A)

Wear ear protectors!

Vibration total values (triaxial vector sum) determined according to EN 60745

Surface grinding: Vibration emission value a

h,SG

8.1

m/s

2

Uncertainty K=

1.5 m/s

2

VIII

1.

2.

1.

2.

For Technical Review, sent on 25 July 2018