8

10/25/2016 - DOCUMENT NUMBER: 10-2500

© 2016 AEM Performance Electronics

AQ-1 DATA LOGGER

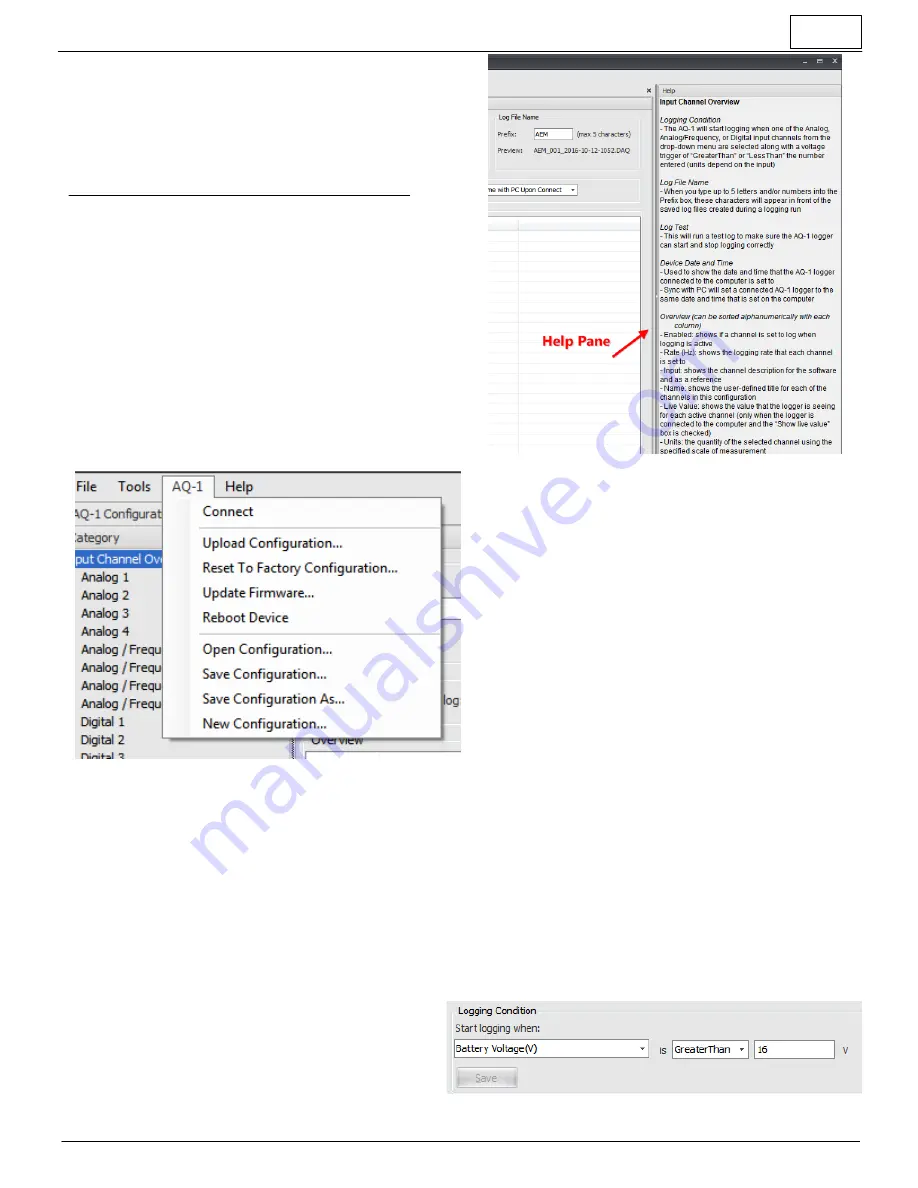

Help Pane

In addition to this manual, detailed information about the

currently viewed page is available in the Help Pane located on

the right side of the screen. The Help Pane may be

collapsed when not needed using the slide control.

Important Notes to Remember When using Software

·

Logger can be configured when powered by USB only but

Permanent 12V at main connector is required for all live

readings and functions to work properly

·

Monitor the Status Bar to determine when the logger is

actively logging; many functions will be disabled while

logging is active to conserve resources

AQ-1 Pull-down Menu

Connect -

Connects (or reconnects) to logger.

Upload Configuration -

Sends logger configuration from PC

to the logger.

Reset To Factory Configuration -

Resets connected logger's

configuration to factory default settings.

Update Firmware -

Do not perform unless instructed by AEM

Technical Support.

Reboot Device -

Performs a reboot of the currently

connected logger. Not typically necessary.

Open Configuration -

Open configuration from PC and edit

offline.

Save Configuration -

Save currently opened configuration to

PC with same filename.

Save Configuration As -

Save currently opened configuration

to PC with different filename.

New Configuration -

Create a new configuration offline and

begin editing.

Configuration: Input Channel Overview / Logging Conditions

This page provides some important interfaces for configuring the operation of your logger. The following things should be

considered when selecting and configuring logging conditions:

·

Logging conditions should be selected such that there is a clear transition to and from logging mode. For example

'Engine RPM > 350'

would provide a clear transition from engine running (logging on) and engine off (logging off.)

Selecting something like

Engine RPM > 2000'

will cause the logger to try and start and stop logging every time the

engine transitions through 2000 RPM which could happen many times within a short duration of time.

·

Logging will start/stop one to two seconds after the logging conditions have been satisfied. This is required to properly

open/close the SD card log file.

Logging Condition

·

Determines when logging starts and stops

·

Select channel, conditional, and threshold

·

Channel must be enabled to be used as a logging

condition