38

If there is even the slightest movement on the fan, never open the fan door!

Fans are components that cannot be taken out of the unit due to their nature (Except for units with sliding fan structure

produced on special request). For this reason, no intervention should be made by the user, except for general controls

about the service.

•

Open the fan module door.

•

Check the fans for dust accumulation, corrosion, or damage.

•

Turn the fan wheel by hand and check for any mechanical friction,

knocking, or clicking noise.

•

Check the tightness of the fasteners in general.

•

If it is Plug Fan, check the vibration wedges for any damage or

loosening.

•

If it is a plug fan, check if there is any laceration in the flexible

connections.

•

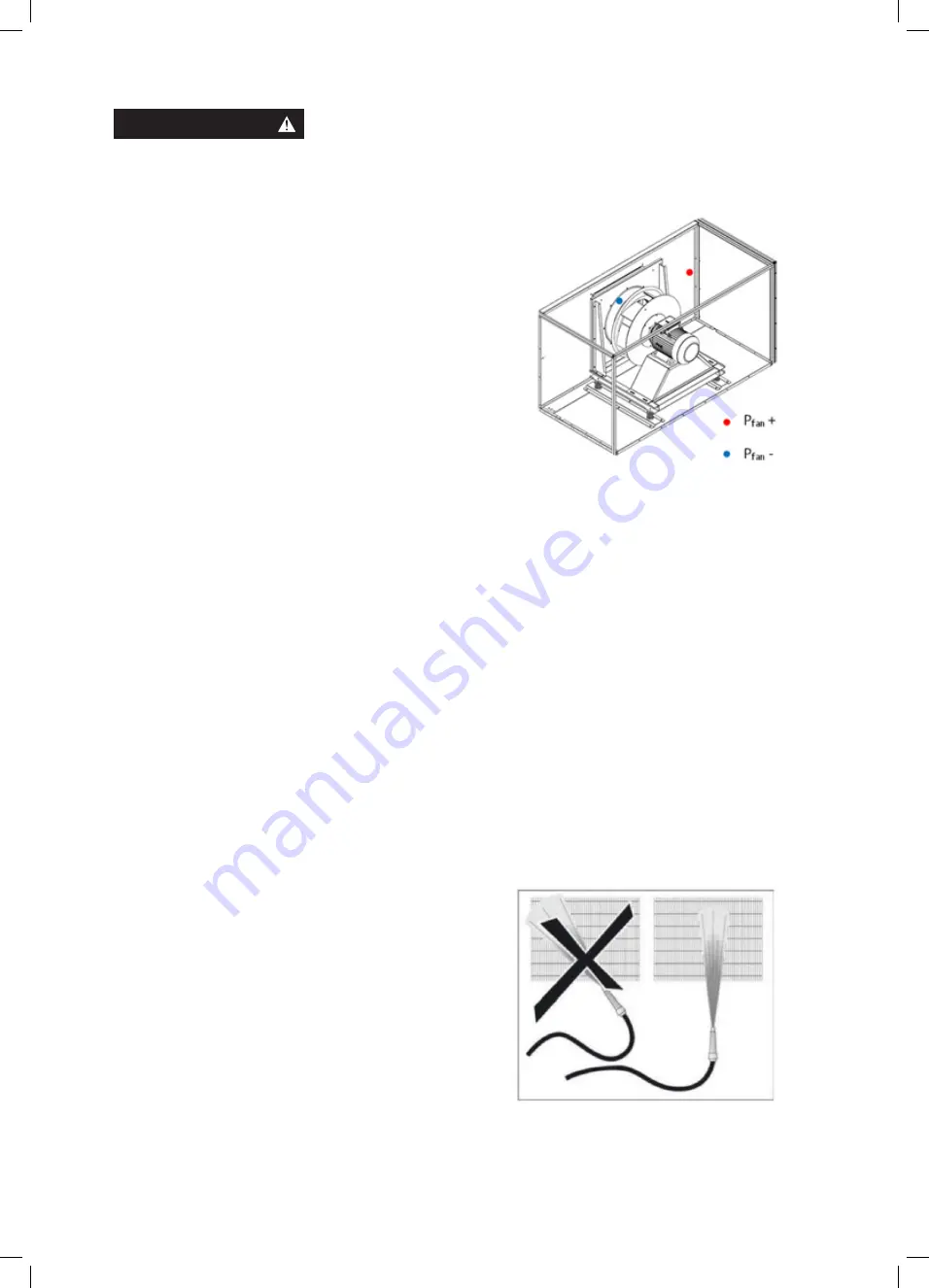

Check the hose connections at the pressure measurement

points.

5.3.4 Coil Maintenance and Cleaning

•

Because the working pressure of the heat exchanger is higher than atmospheric pressure, care should be taken

against any operation that may affect the sealing or cause structural damage (Damages that are generally found

at high temperatures and pressures and may cause internal fluid leakage or emission that could harm people /

the product).

•

All maintenance should be done when the heat exchanger is not operating. Internal fluid must be completely

drained, connections that will impair the tightness must not be loosened until the internal pressure reaches at-

mospheric pressure. The temperature of the product components should not be higher than 35 ° C or ambient

temperature.

•

Before starting the system, make sure that gaskets are placed on all heat exchanger connections.

•

The system should be vented regularly to prevent air from remaining in the cycle.

•

When the heat exchanger is disassembled for any reason, new gaskets must be used. This process will prevent

leaks from seals that become brittle over time due to dehydration.

•

The heat exchanger should never be left filled with fluid while it is not operating to avoid freezing problems.

•

Anti-freezing thermostats should be used.

•

It should be ensured that all parts of the system are clean and in the most suitable condition for working conditions.

Cleaning

•

Heat exchangers should be free of dirt and dust. Dirt/dust

accumulating on the surface will cause a loss of capacity by

forming a layer that will affect the heat transfer.

•

The surface of the heat exchanger should be checked for

dirt and dust and if necessary, cleaned with a soft brush,

compressed air, pressurized hot water, or a similar method.

•

Maintenance should be taken that the high air/water pressure

value used during cleaning does not cause damage / bending

on the coverslips.

•

The washing process should be done parallel to the coverslip

surface. Chemicals that can react with the materials used in

the product should be avoided. When necessary, suitable

chemicals that will not react with the material can be used.

DANGER