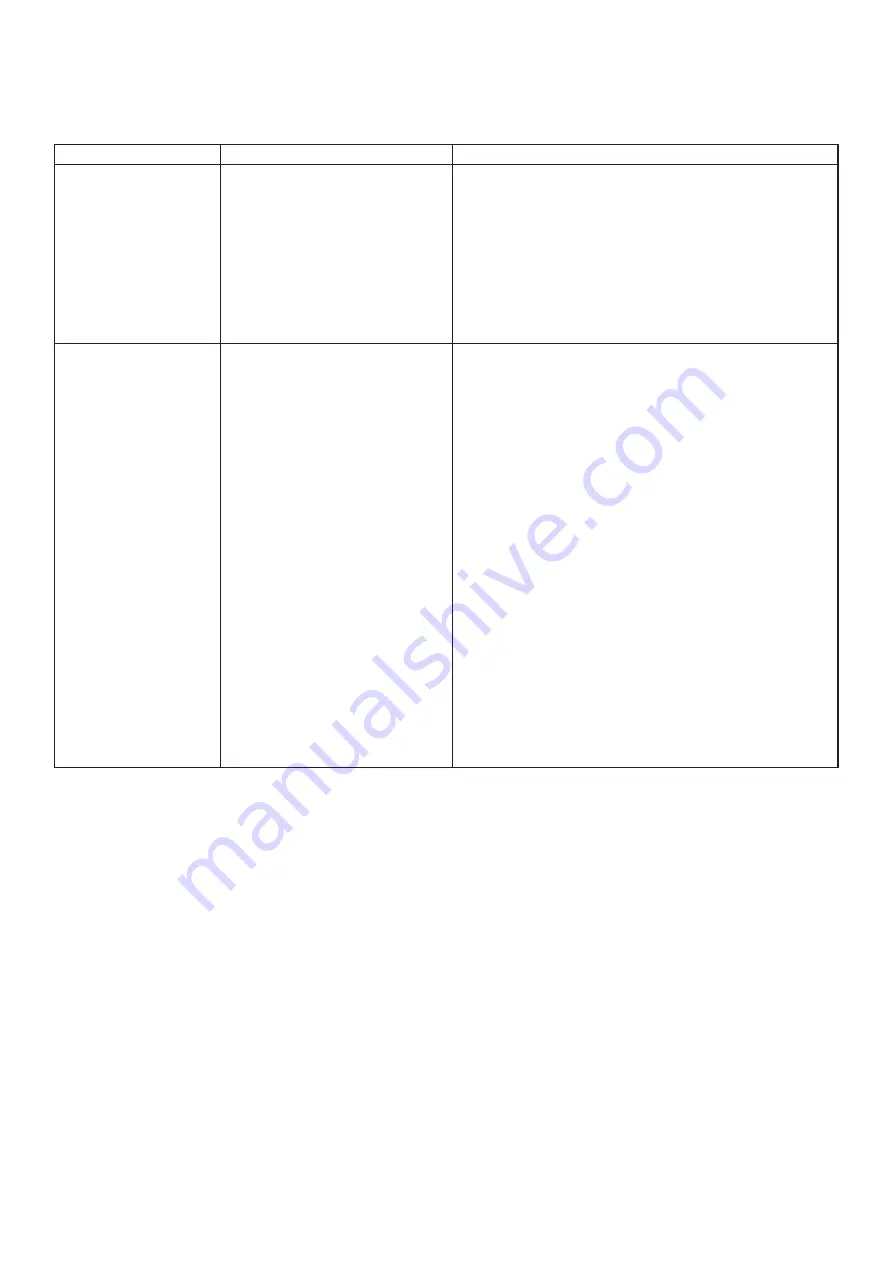

31

• The description of the problem that is the most probable symptom of malfunction;

• The possible cause or causes of damage;

• Suggested solutions;

Finding breakages can be carried out by expert and qualified technical maintenance personnel, who know the machine and the risks connected to it.

PROBLEM FOUND

CAUSE

SOLUTIONS

Lack of capacity (with reduction

of power at normal speed of

rotation)

Eccessive air capacity

Tubes obstructed and/o aspiration points obstructed.

Direction of rotation inverted

Impeller obstructed

Insufficient speed of rotation

Speed of rotation

Clean tubes and hood, check position of the shutters.

Check connection of winding on motor terminal box.

Clean the impeller using the apposite door hatch when the appliance is shut down.

Check voltage and connect the clamps of the motor.

Check transmission, check that the belts do not slide.

Clean tubes and hood, check position of the shutters.

Check direction of rotation; check conditions of turbulence at aspiration; check speed of

motor rotation, voltage, defects in winding.

Insufficient pressure

Reduction of performance after

a satisfactory period of operation

Start up difficult

Excessive noise

Vibrations

Loss of air in the duct system or badly constructed

or installed components , or bypass shutters not

perfectly shut.

Speed of rotation too low

Direction of rotation inverted

Impeller partially blocked and/or damaged

Leakage in volute casings and/or leakage in the

aspiration tubes

Excessive power absorption

Reduced voltage

Elevated number of rotations to obtain the required

performance

Break down of the bearings

Incorrect impeller balancing or impeller scraping on

the volute

Unbalance of the rotating parts

Support structure not suitable

Check the system and substitute the faulty components.

Clean tubes and hood, check position of the shutters

Check electric connection

Check position of assembly and condition of the impeller

Substitute the gaskets and verify the condition of channeling

Check direction of rotation; check the conditions of turbulence at aspiration; check

rotation speed of the motor, voltage, winding defects

Check the data on the motor plate

Use of soundproof systems and/or silencers; choose an appliance with a bigger size

equal to the performance or an appliance with minor peripheral speed

Check bearing wear (in particular for the airtight ones )

Check balancing of the impeller

Check impeller balancing again

Add weights to the structure to make it more stable

Summary of Contents for QPX

Page 2: ...2 ...

Page 35: ...35 NOTES ...