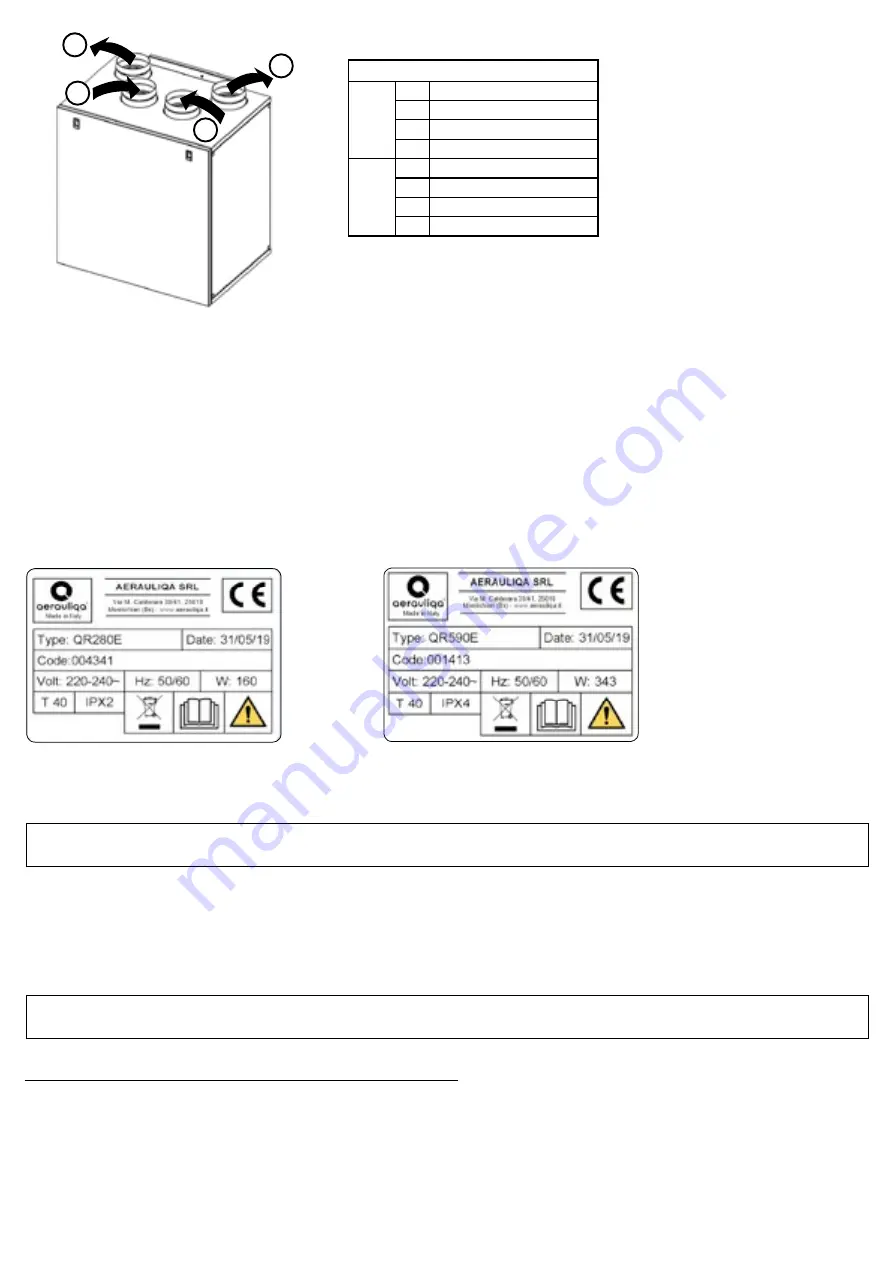

3.5 Rating label

3.4 space required

Make sure that enough space is left around the unit to allow easy maintenance (access to filters, terminal box and removal of the

side and front inspection panels).

To set the RIGHT orientation of the machine:

• Modify the orientation on the CTRL-DSP (§ 7.2 - Installer menu: 3 Machine Orientation).

• For the QR590E units move the F7 filter from the left to the right side.

• Replace the ducting connection label on the top of the casing and the water drainage label on the bottom of the casing with

those supplied with this installation manual.

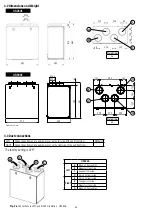

fig.3.c

Rating label

fig. 3.b

Connections in LEFT and RIGHT orientation - QR590E.

4 tRansPoRt and stoRaGE

The appliance is delivered in one carton box.

The appliance should be stored and transported in such a way that it is protected against physical damage that can harm spigots,

casing, display etc...

It should be covered so that dust, rain and snow cannot enter and damage the unit and its components.

WaRninG

Make sure that specific warnings and cautions in Chapter 2 “Precautions” are carefully read, understood and applied!

5 installation

This section describes how to install the unit correctly.

the unit must be installed according to these instructions.

5.1 unpacking

Verify that the unit (and eventual accessories) delivered is according to order before starting the installation. Any discrepancies

from the ordered equipment must be reported to the supplier.

5.2 Where/how to install

• All QR units are meant for indoor installation in a heated space.

• Mount the unit on flat surface (wall).

WaRninG

Make sure that specific warnings and cautions in Chapter 2 “Precautions” are carefully read, understood and applied!

A

B

C

D

QR590E

LEFT

A

Intake air from outside

B

Exhaust air to outside

C

Supply air to inside

D

Extract air from inside

RIGHT

A

Extract air from inside

B

Supply air to inside

C

Exhaust air to outside

D

Intake air from outside

04