20 / 36

TF6790_A_NOT_DXA230_EVOLUTION

Aereco S.A.

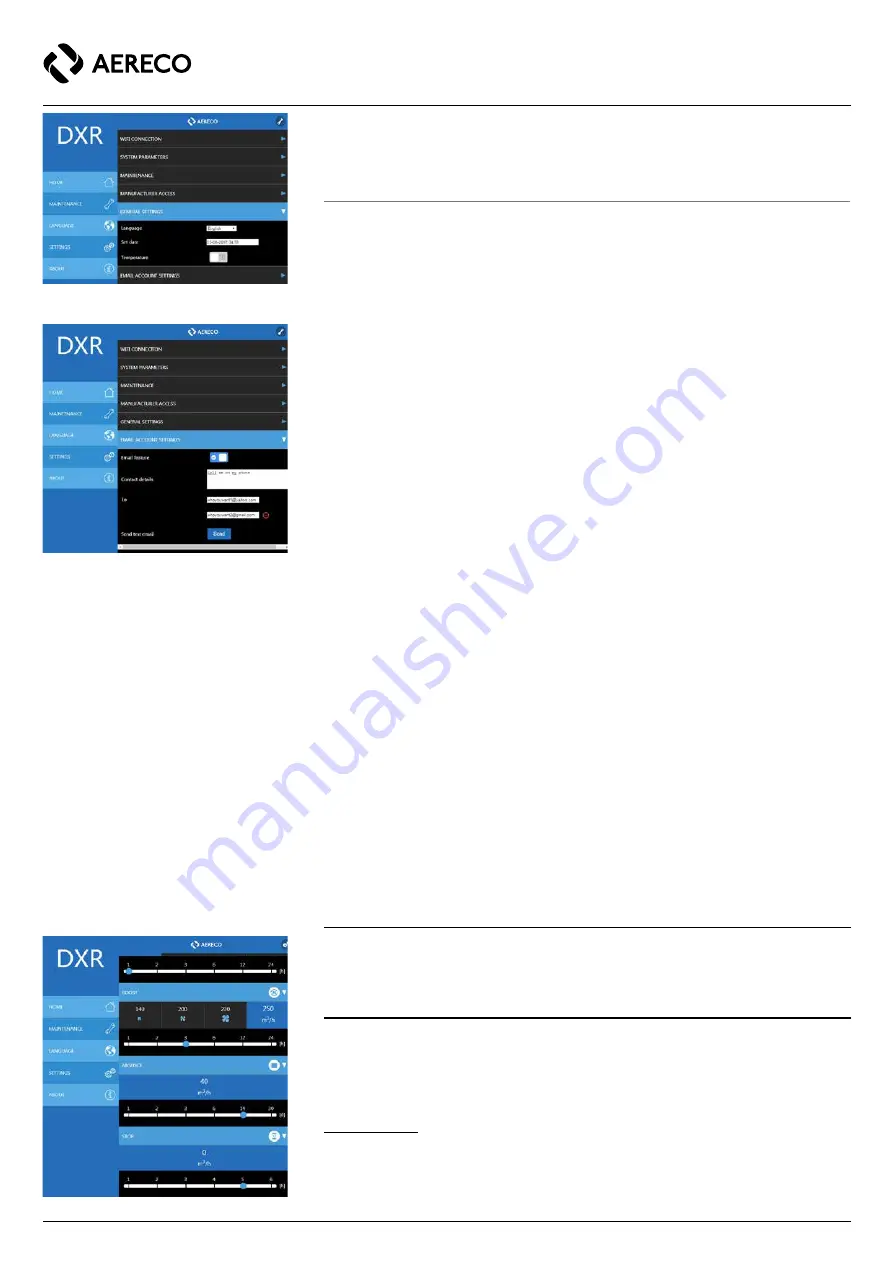

- General settings

- Email account settings

The emailing feature aims the communication of a possible system warning or a fatal error to the

interested people. We suggest one email address should specify the owner’s one and the second

email address should specify the technician in charge of the maintenance. The contact field may

contain some information providing the maintenance technician with the needed customer contact.

The essential points describing the emailing feature are:

1. The emailing of the warnings feature may be enabled/disabled.

2. When enabled, the system send email to one, two or three recipients. Two recipient email

addresses are configurable. The third recipient is the manufacturer, it is predefined and it is

mandatory when you enable this feature.

3. There is a button to test the configuration. When you click it, the system sends email letting you

to check the connectivity.

4. The information sent is:

a. Date and time,

b. Recipients email addresses

c. The text from the contact field

d. The status of the system including the event, the devices composing the system,

their serial number, hardware version, software version, functioning parameters when

the event happened. The status information is sent as a link onto the manufacturer

cloud.

5. The manufacturer collects only the status information in anonymous fashion. The text from

contact field and the email addresses are discarded.

6. To be able to email, the system needs to be connected to Internet through the local LAN (Station

Mode)

7. If you are concerned about the privacy issues you may simply disable the emailing system.

3) LANGUAGE :

Shortcut to Maintenance / general settings with no need of user name and password.

4) SETTINGS :

This menu allows to configure Automatic mode, free cooling mode, Boost mode, Absence mode

and Stop mode within a choice of airflows set points and duration set points.

Automatic mode

, the DXA unit drives the exhaust fan motor in such a way that pressure is a

constant pressure at the exhaust (-80Pa, -100Pa, -110Pa or -120Pa). At the supply, supply fan

motor runs in such a way that at all time, amount exhaust airflows and amount supply airflows are

mass-balanced.