18/36

Aereco S.A.

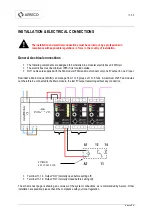

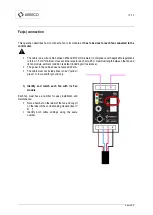

Fan(s) connection

This operation describes how to connect a fan to its modules;

it has to be done for each fan connected to the

control unit.

The cable is a 4 wire cable between Ø6 and Ø12 mm diameter in compliance with applicable regulations

in force: 1,5 mm² minimum cross sectional area for each wire, 25 m maximum length between the fan and

its fan module, ambient condition resistant (including UV resistance).

The power in the cables does not exceed 20 mA.

The cable must not include driver colour "yellow /

green", colour used for ground only.

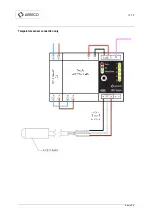

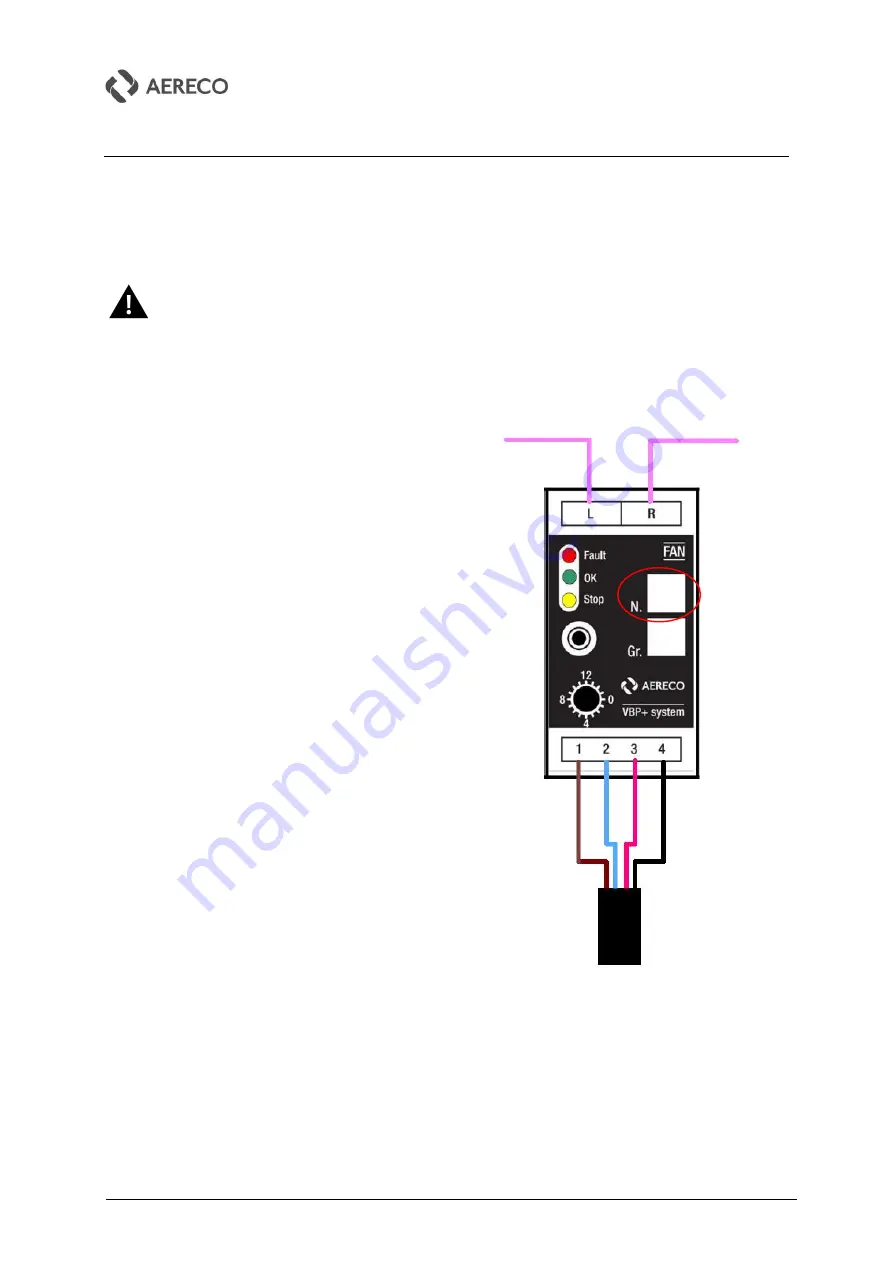

1)

Identify and match each fan with its Fan

module

Each fan must have a number for easy installation and

maintenance:

Note a number on the label of the fan and copy it

on the label of the corresponding module (insert "

N. ").

Identify both cable endings using the same

number.

Summary of Contents for VBP+

Page 11: ...11 36 Aereco S A ...

Page 13: ...13 36 Aereco S A Temperature sensor connection only ...

Page 14: ...14 36 Aereco S A Wind gauge connection only ...

Page 15: ...15 36 Aereco S A Clock connection only ...

Page 16: ...16 36 Aereco S A Temperature sensor wind gauge connection ...

Page 17: ...17 36 Aereco S A Temperature sensor clock connection ...

Page 35: ...35 36 Aereco S A ...