7

5. OPERATION

5.1.

SET POINT IN COOLING MODE. PARAMETER 1STF

(factory

set)=7°C/44.9°F,

∆

t=9°C.

5.2.

SET POINT IN HEATING MODE. PARAMETER 3STC

(factory

set)

=

45C/113°F,

∆

t

=

9°C.

If

the

unit

power

supply

is

restored

after

a

temporary

interruption,

the

set

mode

will

be

kept

in

the

memory.

5.3.

COMPRESSOR START-UP DELAY

Two

functions

have

been

prepared

to

prevent

compressor

start

‐

ups

that

are

too

close.

‐

Minimum

time

from

last

switch

‐

off

180

seconds.

‐

Minimum

time

from

last

switch

‐

on

300

seconds.

5.4. CIRCULATION PUMP

The

circuit

board

delivers

an

output

for

pump

management,

which

starts

on

commissioning

and

remains

on

for

at

least

150

seconds

and

controls

the

state

of

the

probes.

After

the

first

40

seconds

of

pump

operation

the

water

flow

switch

closes

and

the

unit

starts,

when

the

water

flow

rate

is

in

normal

working

conditions,

the

water

flow

rate

alarm

functions

are

acti

‐

vated

(differential

pressure

switch

or

flow

meter).

When

the

ma

‐

chine

enters

stand

‐

by

mode,

the

pump

remains

on

for

30

sec

and

controls

the

flow

meter

or

the

pressure

switch

5.5.

FAN SPEED CONTROL

DCPX ACCESSORY

COOLING OPERATION AT LOW AMBIENT CONDITIONS

AND HEATING OPERATION AT HIGH AMBIENT CONDI-

TIONS.

To

allow

correct

functioning

of

the

unit

at

different

external

tem

‐

peratures,

the

MODUCONTROL

by

reading

the

pressure

via

the

pressure

probe,

controls

the

rotation

speed

of

the

fans,

thus

allow

‐

ing

to

increase

and/or

decrease

heat

exchange,

keeping

the

con

‐

densation

or

evaporation

pressures

more

or

less

constant.

The

fan

functions

independently

with

respect

to

the

compressor.

Remem

‐

ber

that

the

DCPX

is

mandatory

for

the

production

of

DHW.

And

cooling

below

20°C/68°F.

5.6. ANTI-FREEZE ALARM

The

anti

‐

freeze

alarm

is

never

active

if

the

machine

is

off

or

in

stand

‐

by

mode.

In

order

to

prevent

breakage

of

the

plate

heat

exchanger

due

to

freezing

of

the

water

it

contains,

the

MODUCONTROL

stops

the

compressor

if

the

temperature

detected

by

the

probe

postioned

at

the

outlet

of

the

heat

exchanger

and

in

inlet

to

the

chiller

is

below

+4°C/39°F.

THIS

ANTI

‐

FREEZE

SET

TEMPERATURE

CAN

ONLY

BE

VARIED

BY

AN

AUTHORISED

AFTER

‐

SALES

CENTRE

AND

ONLY

AFTER

HAVING

CHECKED

THAT

THERE

IS

ANTI

‐

FREEZE

SOLUTION

IN

THE

WATER

SYSTEM.

The

intervention

of

this

alarm

determines

compressor

stop

and

not

pump

block,

which

remains

active

along

with

the

switch

‐

on

of

the

resistance

if

installed.

To

restore

normal

functions

the

tem

‐

9.

The

voltage

is

within

the

tolerance

of

10%

of

the

unit

nominal

value

10.

Earthing

is

correctly

made.

All

electric

and

hydraulic

connections

are

correctly

tightened.

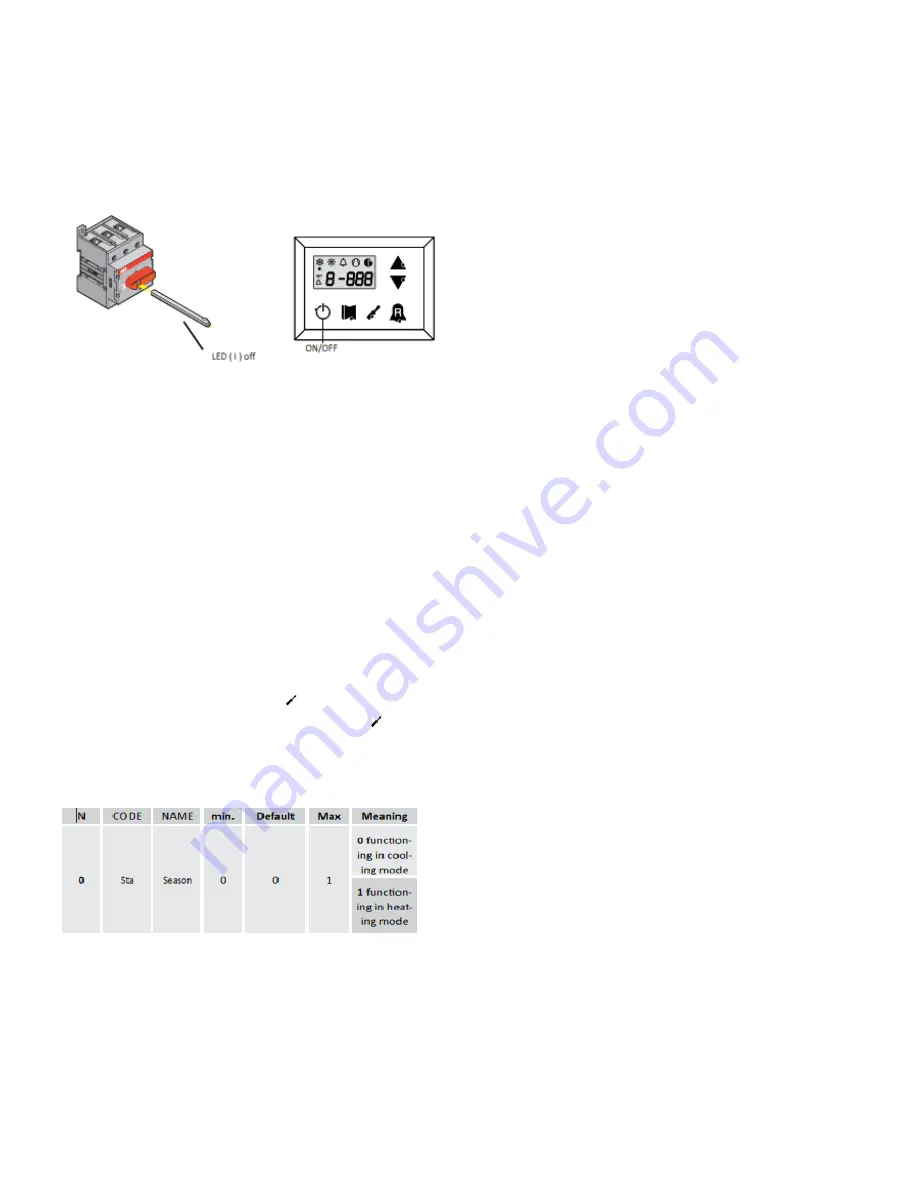

4.2. MACHINE COMMISSIONING

‐

Close

the

electric

control

board

hatch.

‐

Position

the

appliance

master

switch

at

ON.

‐

Make

sure

that

the

auxiliary

switch

contact

(IA)

(see

wiring

diagram)

is

open

(if

used,

and

the

display

LED

(I)A

must

be

off.

‐

Press

the

ON

key

for

3

sec

to

switch

the

machine

on.

4.3. SEASON CHANGEOVER, OPERATION PARAMETERS

‐

For

every

season

change,

check

that

the

functioning

limits

lie

within

the

proper

limits.

‐

Check

that

the

compressor

input

current

is

lower

than

the

maximum

indicated

in

the

technical

data

table.

‐

Make

sure

that

the

voltage

value

lies

within

the

pre

‐

fixed

limits

and

that

unbalance

between

the

three

phases

(three

‐

phase

power

supply)

is

not

above

3%.

SEASON CHANGEOVER FROM PANEL ON MACHINE

Access

the

USER

SET

list

by

touching

the

insert

password

key

000

(already

displayed);

just

confirm

by

re

‐

pressing

the

key

The

parameter

affected

is

the

Sta,

changing

the

value

0

and

1

will

change

the

operation

from

cooling

to

heating

accordingly.

For

further

informa

‐

tion

refer

to

the

USER

MANUAL

SEASON CHANGEOVER FROM PR3

Just

act

directly

on

the

switch.

The

machine

switches

off

automatically

‐

and

switches

back

‐

on

with

the

selected

functioning

mode.

Advance

based

on

the

timeframe

for

the

completion

of

works

for

the

system.

Prior

to

the

work

to

be

carried

out

by

the

AERMEC

service

personnel,

all

other

works

(electrical

and

hydraulic

hook

‐

ups,

priming

and

bleeding

of

air

from

the

system)

must

have

been

completed.