4

QUICK REFERENCE

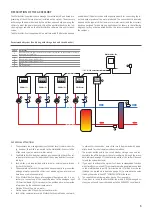

This manual shows all the user menu and installer menu masks contained in the management software of the Multichiller-Evo accessory, however,

this page shows a summary diagram of the basic operations which the user might need, indicating the reference to this manual page which describes

the desired function page (for all other information refer to the index):

Select the functioning mode (Page 15)

Set a main working setpoint (Page 15)

Set the BMS parameters (Page 30)

Switch the unit on or off (Page 15)

Set the time periods (Page 16)

Change system language (Page 21)

REMEMBER THAT:

The Multichiller-Evo accessory is factory set with the data and parameters of the chillers used for the system it is, therefore, necessary,

when ordering, to specify the number and type of chiller that the accessory will have to manage.

ATTENTION: after completing the installation of the Multichiller-Evo accessory, any changes, additions or removal of initially provided

chillers, must be notified to the company for possible adjustment of the application.

Summary of Contents for Multichiller-Evo

Page 2: ......