18

EN

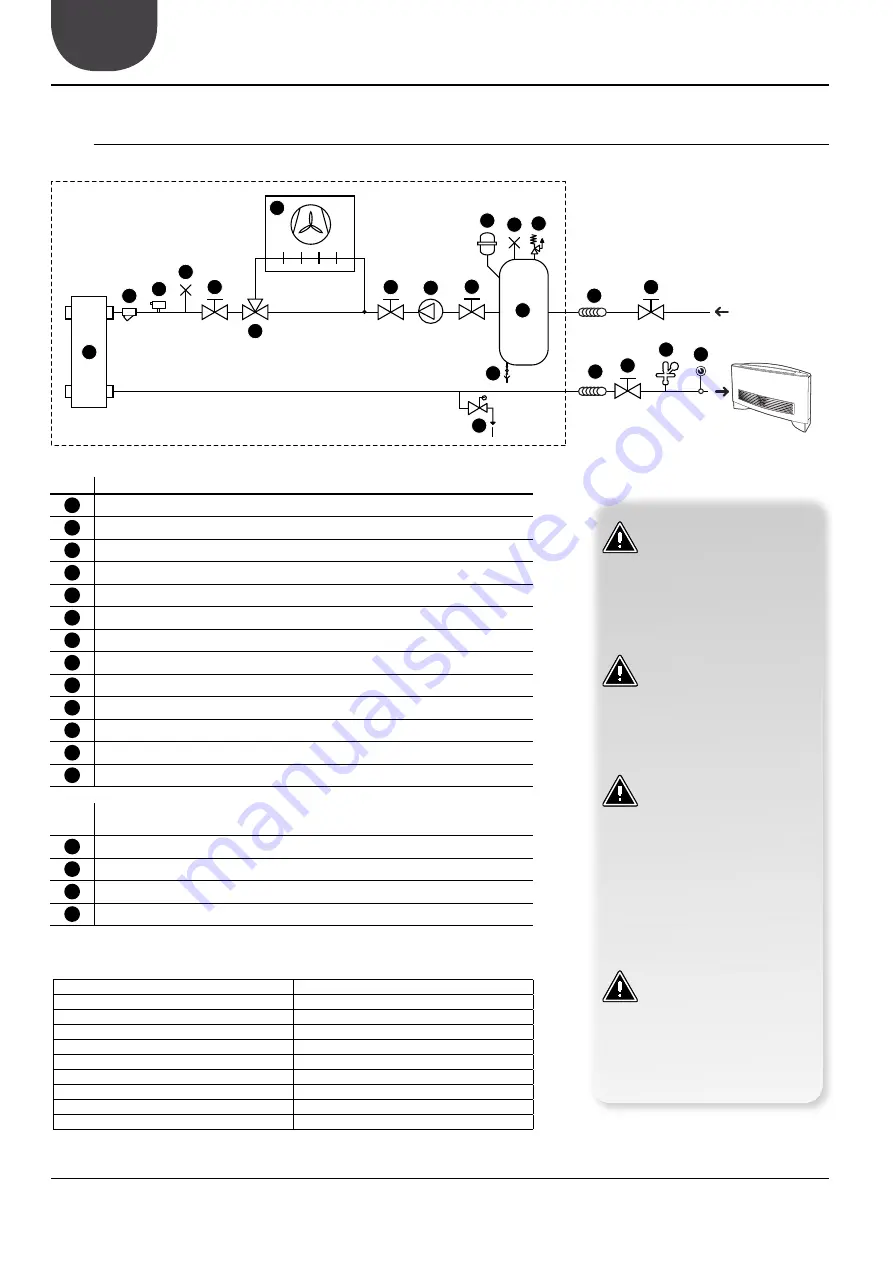

11.2.

HYDRAULIC CIRCUIT (VERSIONS 03-04)

STANDARD COMPONENT

1

Exchanger plate

2

Free-cooling coil

3

Water filter

4

Ball stop

5

Flow switch

6

Air Vent

7

3-way valve

8

Pump

9

Expansion tank

10

Safety valve

11

Storage tank

12

Storage tank ball stop drain

13

Ball stop drain

RECOMMENDED COMPONENTS NOT SUPPLIED

(CHARGED TO THE INSTALLER)

14

Anti-vibration couplings

15

Ball stop

16

Charging unit

17

Manometer

6

1

2

3

4

4

5

6

7

10

13

15

16

17

8

14

14

4

11

15

12

9

hydraulic components NRL 03-04

hydraulic components NOT SUPPLIED

PH

6-8

Electric conductivity

less than 200 mV/cm (25°C/77°F)

Chloride ions

less than 50 ppm

Sulphuric acid ions

less than 50 ppm

Total iron

less than 0.3 ppm

Alkalinity M

less than 50 ppm

Total hardness

less than 50 ppm

Sulphur ions

none

ammonia ions

none

Silicone ions

less than 30 ppm

ATTENTION

The choice and the installation of

components external to the NRL

up to the installer, who must ope-

rate according to the rules of good

technical design and in compliance

with the regulations in force in the

country of destination.

ATTENTION

The hydraulic pipes connecting to

the machine must be properly si-

zed to the actual flow of water re-

quired by the system in operation.

The water flow to the exchanger

must always be constant.

ATTENTION

Carefully wash the plant, before

connecting the unit. This allows

cleaning to remove any residue

such as weld spatter, slag, rust or

other impurities from the pipes.

These substances may otherwise

accumulate in and cause a machi-

ne malfunction. The connecting

pipes should be supported so as

not to weigh, with their weight on

the unit.

ATTENTION

The hydraulic parallel is in charge

of the installer.

NOTE

The drawings are only examples

of the hydraulic circuit.

Summary of Contents for NRL 0280 FE

Page 2: ......