19

21.05 - 6068956_00

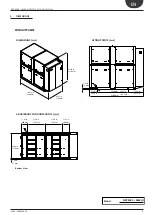

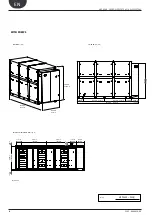

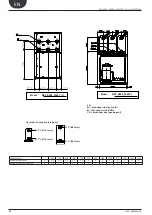

NXP 0500 - 1650 2-PIPE SYSTEM / 4-PIPE SYSTEM

EN

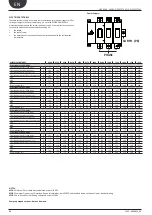

KEY

FUNCTION

ALARMS KEY

Displays the list of alarms and the alarms log;

MENU ACTIVATION KEY

• Pressing this key activates navigation among the menus;

MENU EXIT KEY

• Pressing this key leads to the display of the previous window;

NAVIGATION KEY (+)

• Pressing this key during navigation through the menus/

parameters, allows to pass to the next menu/parameter;

• Pressing this key during parameter modification, increases

the value of the parameter modified;

NAVIGATION KEY (ENTER)

• Pressing this key during navigation through the menus,

allows to enter the selected menu;

• Pressing this key during navigation through the parameters,

allows to select the parameter displayed and enter the mod-

ification mode;

• Pressing this key during parameter modification, confirms

the modification to the value of the parameter selected;

NAVIGATION KEY (-)

• Pressing this key during navigation through the menus/

parameters, allows to pass to the previous menu/parameter;

• Pressing this key during parameter modification, decreases

the value of the parameter modified;

User interface (pGD1)

The NRP unit control panel allows quick se� ng

of the machine functi oning parameters and their

display.

The display is made up from a graphical matrix

with 132 x 64 pixel in order to signal the type of

functi oning, displaying set parameters and any

alarms that have intervened.

All default se� ngs and any modifi cati ons are

memorised in the board.

With the installati on of the PGD1 remote panel,

all of the functi ons and se� ngs available on the

machine can be replicated at a distance.

A� er a power cut, the unit can re-start automati -

cally keeping the original se� ngs.

The user interface is represented by a graphic dis-

play with six keys for navigati on.

The displays are organised via a menu hierarchy,

which can be acti vated by pressing the navigati on

keys. The default for displaying these menus is

represented by the main menu.

Navigati on between the various parameters takes

place using the arrow keys positi oned on the right

side of the panel. These keys are also used to

modify the parameters selected.

INTERFACE CONTROL KEYS

Control keys

Control keys

WARNING

Tampering of parameters contained in the assistance and the manufacturer menu

can cause unit malfunctioning. It is therefore recommended that these parameters

are modifi ed only by authorised staff.

ATTENTION

The

2-pipe

is set up for the producti on of

cooled water, hot water and Domesti c Hot

Water (D.H.W.).

- No Anti -legionella Cycle is included

The

4-pipe

is set up for the producti on of

cooled water and hot water.

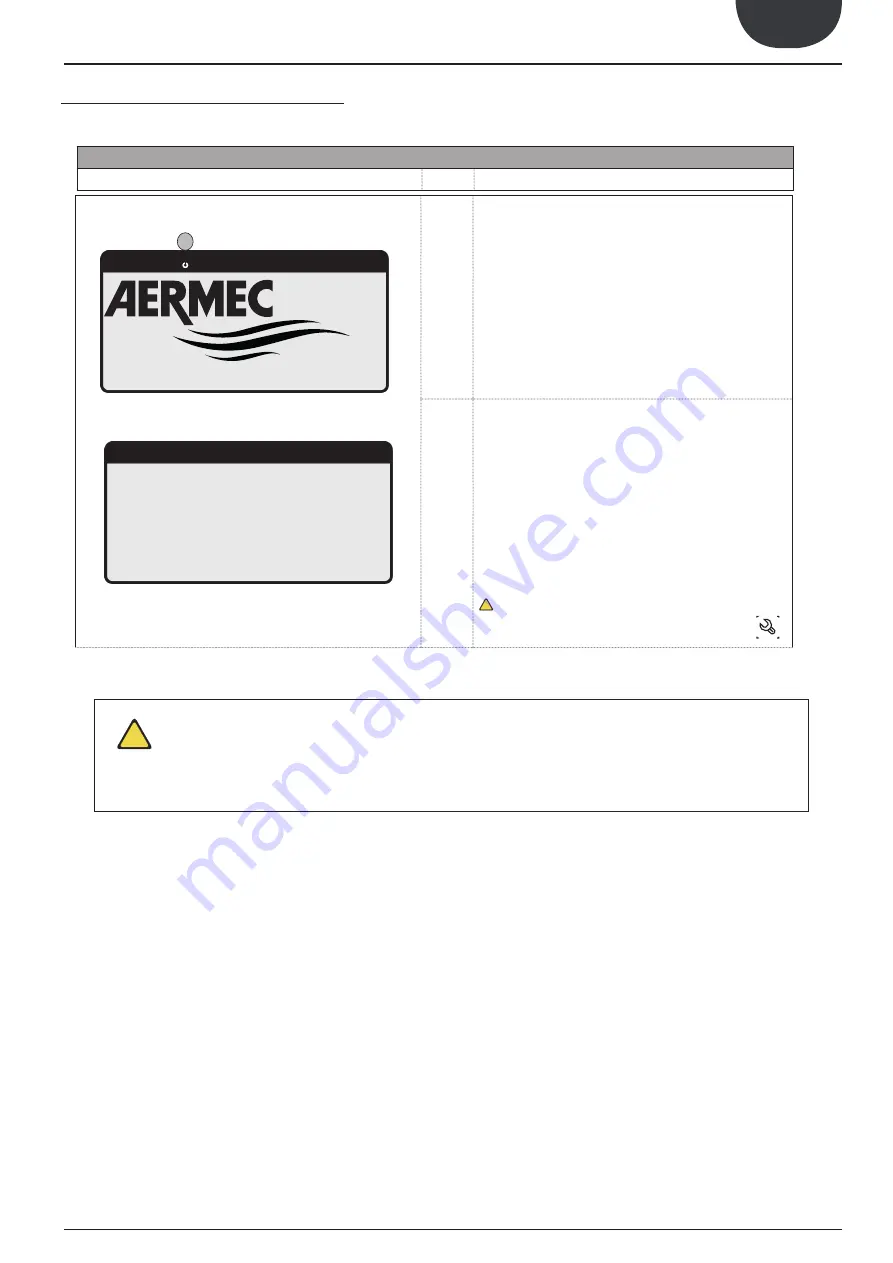

Displays - Switching Unit on

The following table shows the windows visible for the user when the unit is powered.

WARNING

tampering of parameters contained in the assistance and the manufacturer menu can cause unit malfunc-

ti oning. It is therefore recommended that these parameters are modifi ed only by authorised staff .

L a n g u a g e

L a n g u a g e

E N G L I S H

E N T E R f o r c h a n g e

E S C t o c o n f i r m

T i m e s h o w m a s k

20

W a i t p l e a s e

6s

A

Displays - Switching Unit on

Unit display

Index

Display/Parameter

A

Introductory window, visible 30 seconds after unit is

switched on.

The seconds remaining before passing on to the

language choice menu are indicated at the bottom

right.

B

Indicates the possibility of choosing the desired lan-

guage.

The seconds remaining before passing on to the

main screen are indicated at the bottom right.

After 20 seconds have elapsed, it will no longer be

possible to modify the language until the next time

the board is restarted.

The language can be modified by qualified per-

sonnel alone, using the ASSISTANCE MENU.

12.

DISPLAYS - SWICHTING UNIT ON