26

21.05 - 6068956_00

NXP 0500 - 1650 2-PIPE SYSTEM / 4-PIPE SYSTEM

EN

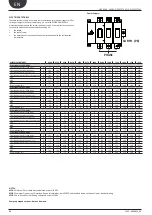

L1

L2

L3

PHASE

EARTH (PE)

Power Supply:

ELECTRIC DATA TABLE

The cable sections shown in the table are recommended for maximum lengths of 50 m.

For longer lengths or different cable laying, it is up to the DESIGN ENGINEER to

dimension the appropriate line switch, the power supply line as well as the connection

to the earth wire and connection cables depending on:

•

the length;

•

the type of cable;

•

the absorption of the unit and the physical location and also the environment

temperature.

NOTES

:

MCA

: Minimum Circuit Ampacity calculated as per UL1995

MOP

: Maximum Overcurrent Protective device calculated as per UL1995 and rounded down to the next lower standard rating

SCCR

: Short-Circuit Current Rating calculated as per UL1995

Pumps equipped versions: data on demand

ELECTRICAL DATA NXP

0500

0550

0600

0650

0700

0750

0800

0900

1000

1250

1400

1500

1650

Power supply 230V/3~/60Hz

Total input current in cooling mode

A

93

91

102

112

127

140

186

196

209

238

264

303

341

Total input current in heating mode

A

104

106

117

131

148

163

211

226

243

276

307

353

400

Total input current in recovery mode

A

105

106

118

132

148

162

210

224

242

274

304

349

395

Total input current c recovery mode

A

105

107

118

132

149

162

211

225

243

275

306

352

398

LRA

A

404

381

421

361

433

456

532

709

734

853

892

917

979

MCA

A

125

131

136

142

182

218

237

278

314

340

362

417

466

MOP

A

181

182

192

175

233

269

293

352

388

425

448

527

575

Recommended fuse

A

175

175

175

175

225

250

250

350

350

400

400

500

500

Power supply 460V/3~/60Hz

Total input current in cooling mode

A

42

41

46

51

57

63

84

89

95

108

120

137

154

Total input current in heating mode

A

47

48

53

59

67

74

96

102

110

125

139

160

181

Total input current in recovery mode

A

47

48

53

60

67

73

95

102

109

124

138

158

179

Total input current c recovery mode

A

48

48

53

60

67

74

95

102

110

124

138

159

180

LRA

A

208

187

216

180

210

220

266

318

328

384

402

454

482

MCA

A

62

67

72

79

89

98

115

124

132

158

181

209

234

MOP

A

88

89

98

97

112

121

141

154

163

200

223

264

289

Recommended fuse

A

80

80

90

90

110

110

125

150

150

200

200

250

250

Power supply 575V/3~/60Hz

Total input current in cooling mode

A

32

32

36

39

44

49

65

68

73

83

92

105

119

Total input current in heating mode

A

36

37

41

46

51

57

74

79

85

96

107

123

139

Total input current in recovery mode

A

36

37

41

46

52

56

73

78

84

95

106

122

138

Total input current c recovery mode

A

37

37

41

46

52

57

73

79

85

96

107

123

139

LRA

A

154

137

160

122

155

163

199

251

260

324

338

350

371

MCA

A

56

53

58

57

73

87

103

105

107

130

150

183

212

MOP

A

79

73

81

70

92

107

127

130

131

164

185

232

261

Recommended fuse

A

75

70

80

70

90

100

125

125

125

150

175

225

250

Power supply 208V/3~/60Hz

Total input current in cooling mode

A

102

101

113

124

140

155

205

217

232

263

292

335

378

Total input current in heating mode

A

115

117

130

145

163

180

234

250

269

305

339

390

442

Total input current in recovery mode

A

116

117

130

145

164

179

232

248

267

303

336

386

437

Total input current c recovery mode

A

116

118

130

146

164

180

233

249

268

304

338

389

440

LRA

A

411

390

430

374

447

472

553

731

758

879

922

950

1019

MCA

A

132

137

143

148

188

224

243

284

320

346

369

423

472

MOP

A

188

188

198

181

240

275

299

358

394

431

454

533

582

Recommended fuse

A

175

175

175

175

225

250

250

350

350

400

450

500

500