8

20.05 – 4138421_03

DISEGNO SPECIFICO DEL MODELLO-

SOLLEVAMENTO UNITÀ CON CINGHIE,

CORDE O FUNI

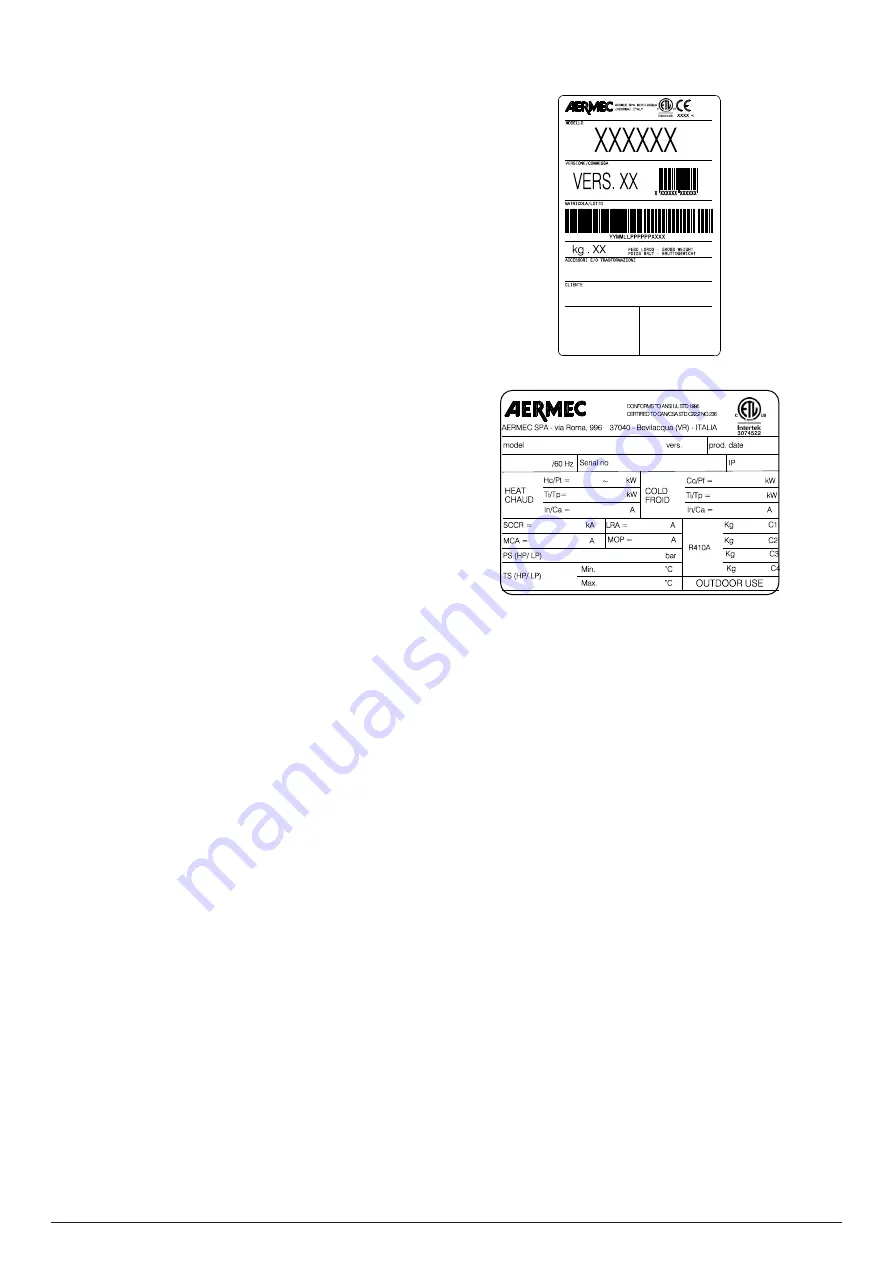

Packaging label

Technical plate

RECEPTION

TRANSPORT

AND

HANDLING

The unit must be handled by qualified personnel. Carefully follow the

lifting instructions on the labels placed on the unit.

The unit must be lifted with extreme care to prevent knocks to the frame,

panels, electrical panel, etc..

NOTE: Plastic elements can be used to protect the units against damage

during transport. The machine is also wrapped in packaging. We recom-

mend keeping this protection during all transport and lifting operations

and not remove the plastic elements until commissioning.

If the unit has anti-vibration supports, they must be installed on the unit

before final positioning.

Inspection upon receipt

Perform the following check upon receipt of the product.

- Check that the exterior has not been damaged in any way.

- Check that the lifting and transport devices are appropriate to the

type of equipment and compliant with the transport and handling

instructions attached to this manual.

- Check that the accessories required for on-site installation have been

delivered and are operational.

- If the unit is provided pre-loaded with refrigerant, make sure there have

been no leaks.

- Check that the equipment supplied corresponds to the order and

delivery note

Product identification

The Aermec products can be identified by the

packaging label

bearing

the identification data of the product and by the

technical plate

bearing

the performance and technical data of your unit.

If the product is damaged, send a registered letter with the details of

the problem to the shipping company within 48 working hours from

delivery.

LIFTING

Before lifting the unit, place protections between the belts (or ropes and

chains) and the framework to prevent damage to the structure.

CAUTION: ALWAYS USE ALL THE UNIT LIFTING POINTS PROVIDED

• Follow all safety regulations and standards

• Wear safety glasses, work gloves and safety shoes

• Pay the utmost attention to heavy and bulky equipment during lifting

and handling, and when placing it on the ground.

• All panels must be tightly fixed before moving the unit

• Before lifting, check the specific weight on the technical plate.

• Use all, and only, the lifting points indicated;

• Use ropes in compliance with Standards and of equal length;

• Use a spacer in accordance with the sling (not included) see drawing

• Handle the unit with care and without sudden movements

• Do not stand under the unit during lifting

Attention: the units cannot be stacked

RECEPTION

Technical plate

Packging label

Summary of Contents for NYB

Page 2: ......