SM321009D

Page 5 of 9

©Aero-Motive Nov-03

MAIN SPRING REPLACEMENT

WARNING:

To prevent personal injury, death or property damage,

hold center of spring down as the hub is pulled out. If the

center is allowed to rise up, the spring may escape from

its container. Hazards or unsafe practices COULD result

in

severe

personal injury or death. DO NOT remove the

spring from its container.

WARNING:

To prevent personal injury, death or property damage, handle all springs with care. Use

suitable protective gloves for spring handling. Hazards or unsafe practices COULD result

in

severe

personal injury or death.

NOTE:

It is recommended to replace all springs since unbroken springs of same age will likely need

replacement very soon as well. Failure to do this will result in much more frequent maintenance.

It is advisable to wear gloves or other suitable hand protection since sharp edges may be encountered

when handling springs. Follow same instructions as for collector ring replacement above. Remove four

hex head cap screws on the goose neck fitting, then remove from entrance ring. Remove six bolts on

entrance ring and pull off main shaft along with driving ring and spacer. Remove spool so spring and cup

assemblies are exposed.

Each spring assembly can now be removed in their cup shaped containers. Lift each spring off main shaft

being careful to disengage the hub first by rotating it in the tension reducing direction until a click is heard

and hub is unhooked. Grab under each edge with your hands to help hold the spring in the pocket while

lifting off and until it is safely right side up on bench. If spring is pulling out of pocket stop process and

attempt to disengage.

The parallel spring 1300 and 1500 series units come with interlocking parallel spring pockets and with

doublewide hubs. If the hub starts coming off with the top spring do not be alarmed. Just make sure it

doesn’t pull the spring out of pocket.

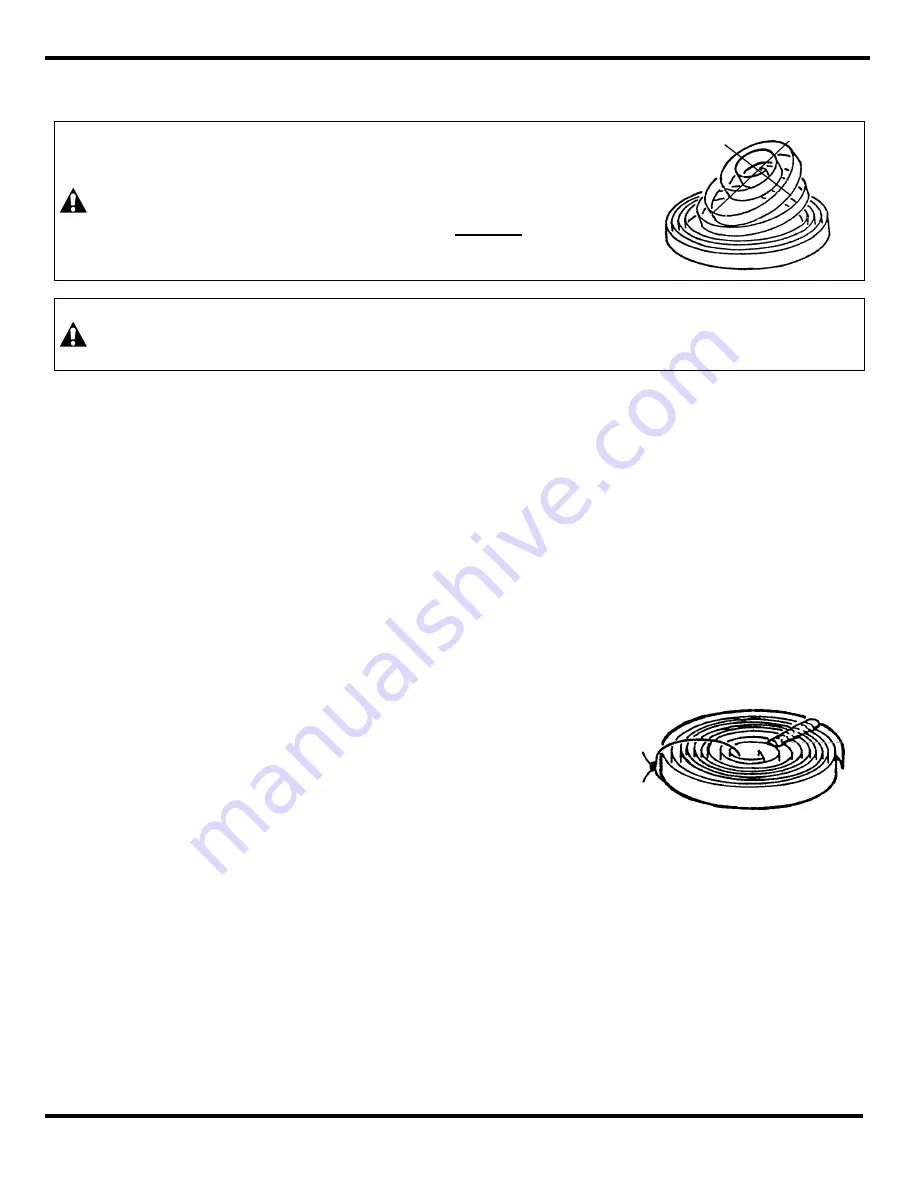

When disposing of old or broken spring assemblies, coils should

be welded or wired together to prevent possible injury to scrap

handling personnel. Replace broken spring assembly, and

reassemble the springs in reverse order. When replacing spring

assemblies make sure that the square projection, on the end of

the spring hub below, is properly engaged in the opening of

adjacent spring cup.Refer to parts drawing for part sequence and

location.

LUBRICATION

Springs and bearings have been sufficiently lubricated at the factory to last for the normal life of

the motor. If grease has been removed during maintenance it should be replaced with good quality high-

low, temperature grease (Texaco AFB 2 or equal). Bearings should be packed, and springs should have

enough grease in the cup to thoroughly coat the entire spring as it works in during use.