AEROMOTIVE, INC.

7805 Barton Street, Lenexa, KS 66214

913-647-7300 fax 913-647-7207

Note: Be sure to route all electrical wires clear of any moving suspension or drivetrain components and any

exhaust components! Protect wires from abrasion and road obstructions or debris.

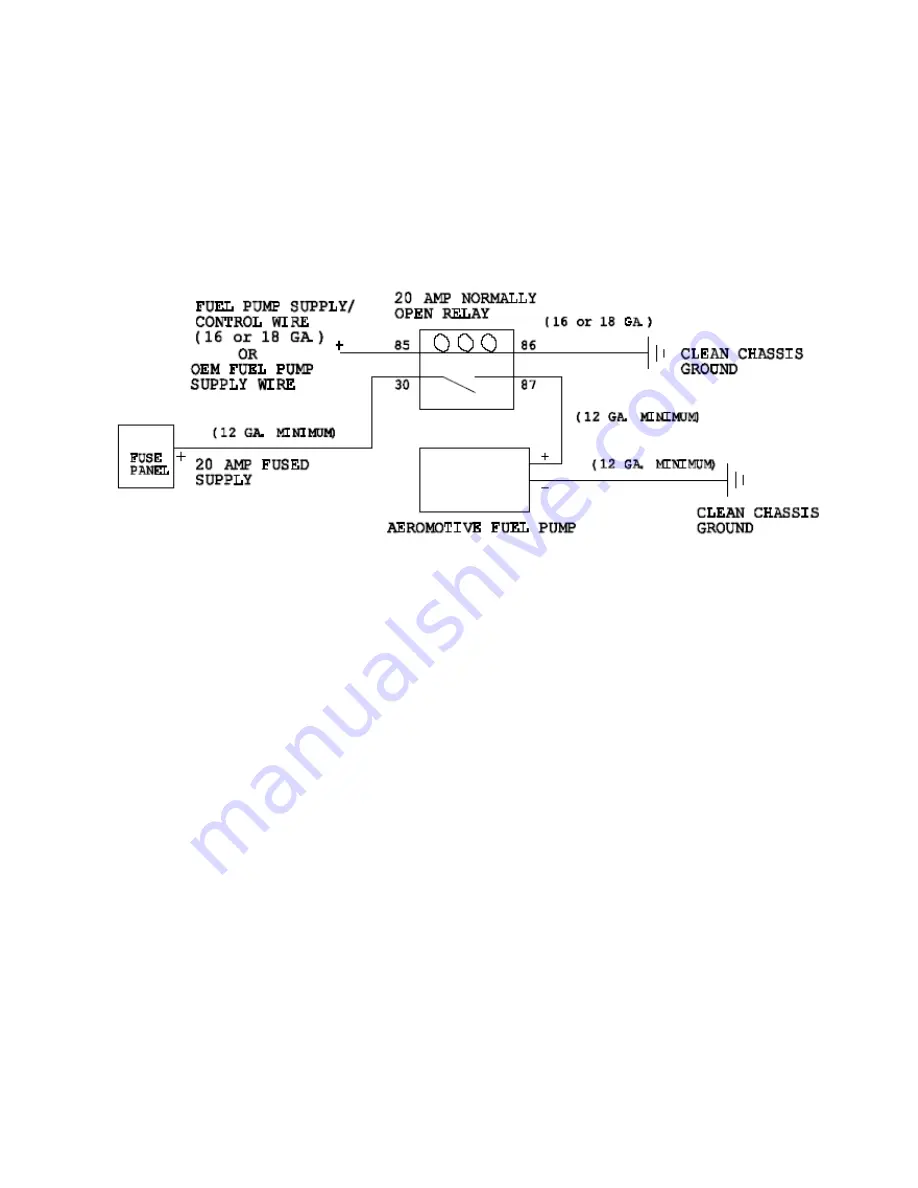

9. There are two ways to connect electrical power to the pump, depending on your fuel injection system. Make sure you

use stranded, insulated copper wire, in the sizes shown, with matching crimp-type connectors for all connections. If

your vehicle has an after-market ECM(Electronic Control Module) for running the fuel injection system, use step 10. If

your vehicle has an OEM ECM, use step 11.

10. Locate the OEM fuel pump supply wire, if using an after-market ECM, locate the electrical terminal that controls the

fuel pump. From that terminal, connect the Aeromotive fuel pump as shown in the following diagram.

11. Attach a suitable fuel pressure gauge to the fuel system schrader valve, fuel rail or fuel pressure regulator.

12. Ensure that any spilled fuel and any fuel soaked shop towels are cleaned up and removed from the vicinity of

the vehicle!

CAUTION:

While performing the following steps, if any fuel leaks are detected, immediately turn the ignition to

OFF, remove any spilled fuel and repair the leak(s) before proceeding!

14. Turn the ignition to ON without starting the engine, allow the pump to run for several seconds and check the fuel

pressure. If there is no pressure, turn the ignition to OFF, wait one minute, then turn the ignition to ON and recheck the

pressure. Repeat this ignition OFF and ON procedure until the gauge registers pressure or you detect a fuel leak. If no

pressure is registered on the gauge after running the pump for several seconds and you have found no leaks, check

all fuel and electrical connections to determine the cause.

15. Once the fuel pressure gauge registers pressure, start the engine. The fuel pressure gauge should register between

40 and 70 psi. If you have installed an adjustable fuel pressure regulator, adjust it to the desired setting.(For maximum

fuel system performance, we recommend using an Aeromotive adjustable fuel pressure regulator; call us for info.)

16. Shut the engine off. Using suitable clips and other mounting hardware, secure the newly installed fuel lines and

electrical wires by attaching them to the vehicle chassis.

17. Carefully lower the vehicle to the ground.

18.

Test drive the vehicle to insure proper operation and re-check the fuel system for leaks. If any leaks are found,

immediately discontinue use of the vehicle and repair the leak(s).