Twinspeedy / Sailspeedy

Sailspeedy / Twinspeedy instructions

2

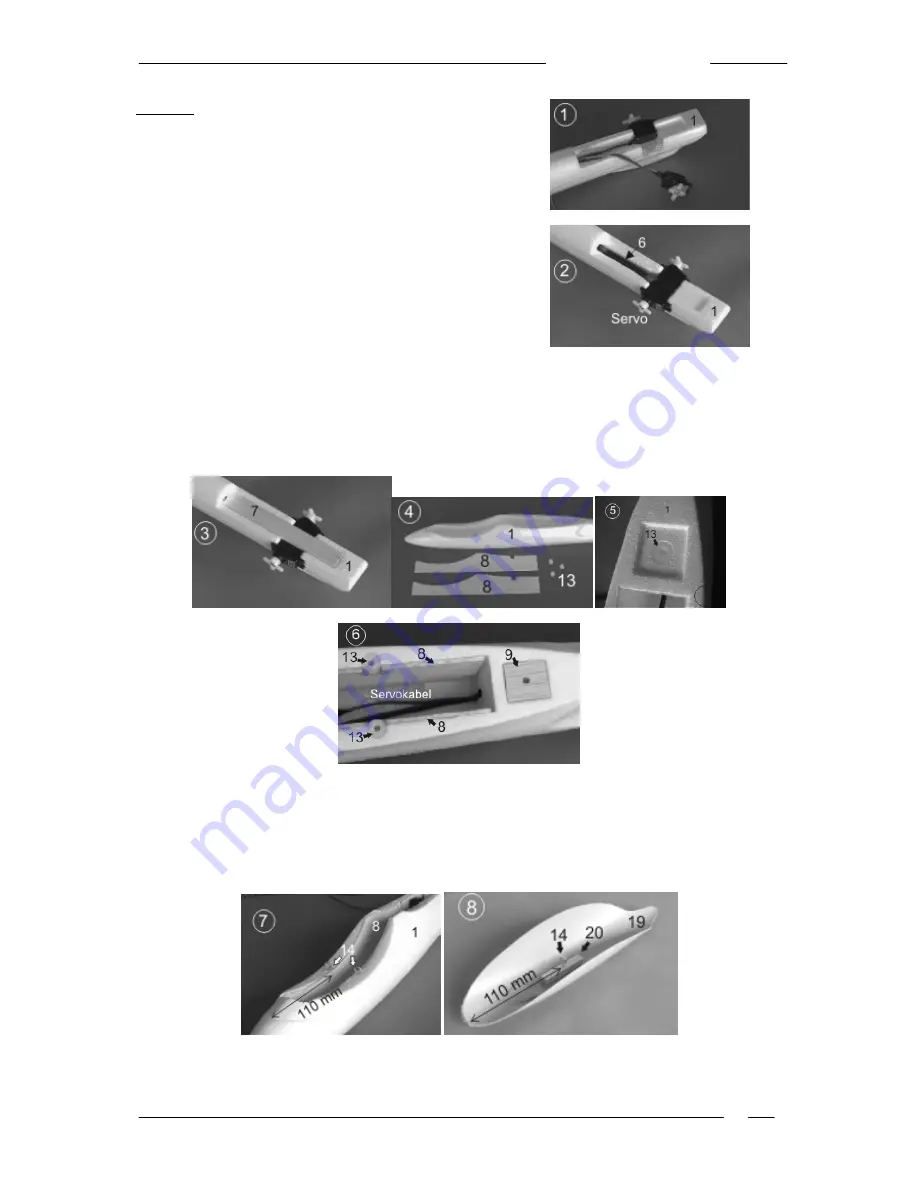

Fuselage

The V-tail servos are mounted at the tail end of the fuselage,

and have to be extended to a length of 65 cm to reach the RC

system receiver, which is housed under the canopy at the front.

Please read the instructions supplied by your RC system and

servo manufacturer regarding extension leads, as suppressors

may be required.

Test the servos to ensure that they work correctly after they are

fitted with the extension leads. Wrap clear tape round the servo

leads for a distance of about 8 cm to protect them from the

epoxy. Glue the two servos in the tail of the fuselage (1), run the

leads through the hole in the fuselage (1) and allow them to

hang down (Fig. 1).

The next stage is to epoxy the carbon fibre tube (6) in the

fuselage (1) to stiffen and strengthen it.

Slip the carbon fibre tube (6) into the fuselage (1) from the canopy end and position it just short of the

servos at the tail end; the servo leads should be below the carbon fibre tube (6) (Fig. 2). Glue the

balsa plate (7) in the recess at the tail of the fuselage (1) to stiffen it. It should fit over the two servos

and the carbon fibre tube (6) (Fig. 3).

Run the servo leads forward into the cabin area (Fig. 6). Seal the underside of the fuselage by gluing

the balsa strip (12) in the channel; it should end flush with the outside skin of the fuselage.

Glue the sheet balsa doublers (8) in the front part of the fuselage (1) on both sides of the cockpit

recess (Figs. 4 + 6).

Three threaded nylon sleeves (13) have to be glued in the fuselage (1) to accept the wing retaining

screws: one on each side of the fuselage (1), where they are attached to the balsa doublers (8), and

the third in the circular recess at the rear of the wing saddle (Fig. 5). The balsa reinforcement (9) is

then glued on top of the third sleeve (13) (Fig. 6).

The two ring-screws (14) can now be glued between the sides of the fuselage (1) and the balsa

doublers (8): press the ring-screws (14) into the fuselage, then enlarge the holes and epoxy the ring-

screws securely to parts (1 + 8) (Fig. 7). These ring-screws are used to attach a rubber band (22)