Operating Instructions

Air Supply

1.

Ensure the air valve (or trigger) is in the “OFF” position before connecting to the air supply.

2.

You will require an air pressure of 90psi, and an air flow in accordance to the specification.

3.

WARNING:

Ensure the air supply is clean and does not exceed 90psi while operating the air

tool. Unclean air or too high an air pressure will shorten the product life due to excessive wear

and may be dangerous, causing damage or personal injury.

4.

Drain the air tank daily. Water in the air line will damage the air tool.

5.

Clean air inlet filter weekly.

6.

Line pressure should be increased to compensate for unusually long air hoses (over 8 metres).

The hose diameter should be 3/8” I.D.

7.

Keep hose away from heat, oil and sharp edges. Check hose for wear and make certain that all

connections are secure.

Lubrication

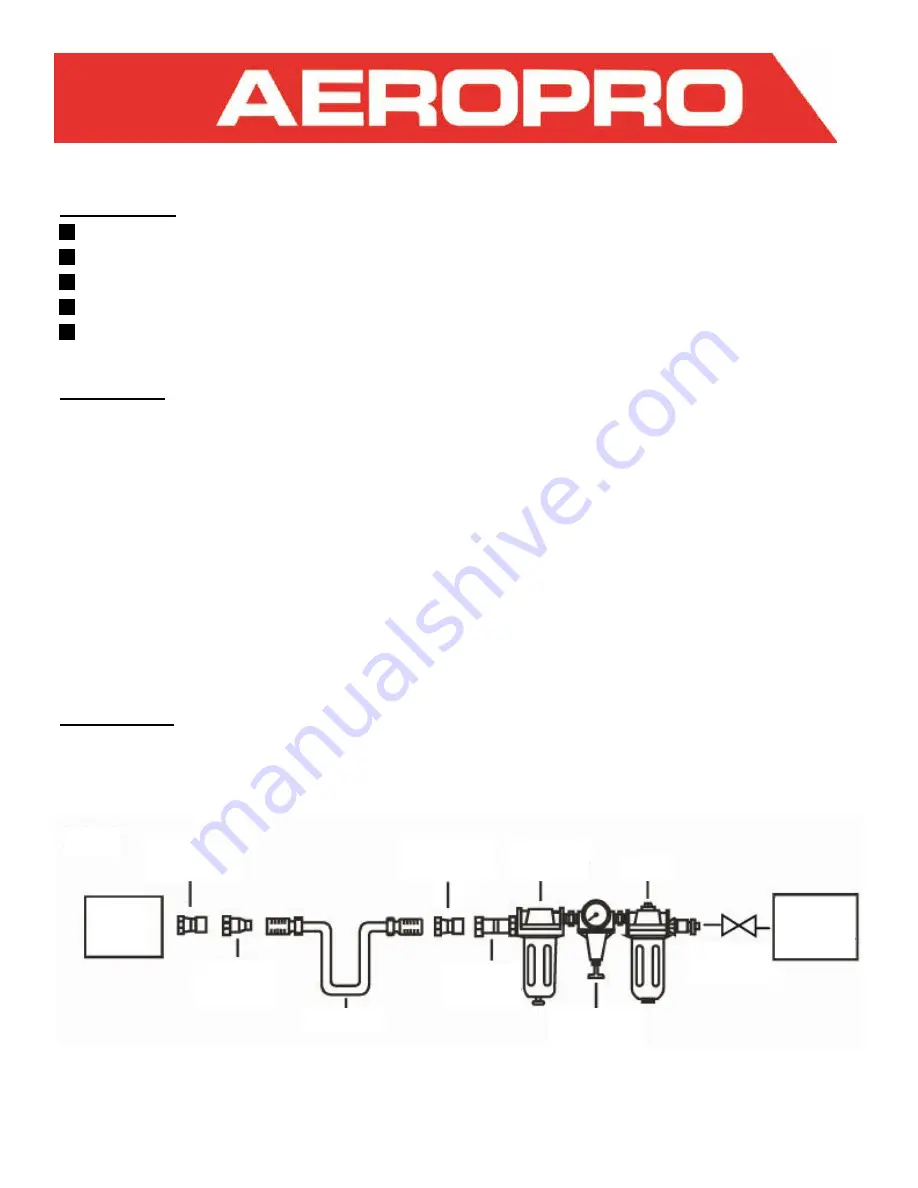

An in-line filter-regulator-lubricator with automatic drain is recommended (Fig 1.) as it increases the

tool life and keeps the tool in sustained operation.

The in-line lubricator should be regularly checked and filled with air tool lubrication oil. Excessive

amounts of oil should be avoided.

Fig 1.

Tool

Quick

Connector

Quick

Coupler

Air Hose

Lubricator

Regulator

(0 - 8.5 Bar)

Air

Compressor

Filter

Quick

Connector

Quick

Coupler

Shut-off

Valve

Description

Designed for drilling, honing and hole sawing and other heavy duty applications.

Reversible and keyless air drill.

Durable lightweight aluminium housing.

Variable speed trigger.

Hand exhaust reduces noise and directs air away from work surfaces.