2

Air Coil Nailer

Http://www.aeroprotools.com

1.

Technical data

Type of tool

MCN55 & MCN55B

Recommended lubricant

white mineral oil 10

#

Outline dimension

283*270*131mm

Maximum allowable pressure

8,3 bar

Weight (without fasteners)

2.7 kgs

Recommended allowable pressure range

5.8 to 8 bar

Activation mode

contact actuation

1.1 Fastener

Fastener size for MCN55B: Dia.2.5-2.7mm, Nail length: 25-55mm,

Magazine capacity: 300-350pcs

Fastener size for MCN55: Dia.2.1-2.3mm, Nail length: 25-55mm,

Magazine capacity: 300-350pcs

1.2 Accessories

Hexagon Key, Goggles, Lubricant, Operating instruction

1.3 Description/Features

Features and Benefits: MCN55B Air coil nailer

have light weight, rugged magazine and drives 300-350 nails continuously by

full-loading, multi-directional exhaust, comfortable rubber grip, equipped with dust cover and body protector.

Application:

1. Making pallets, drums and export wooden boxes, 2. Crating 3.Making wooden fence, 4.General construction

applications including siding, decking and sheathing and etc.

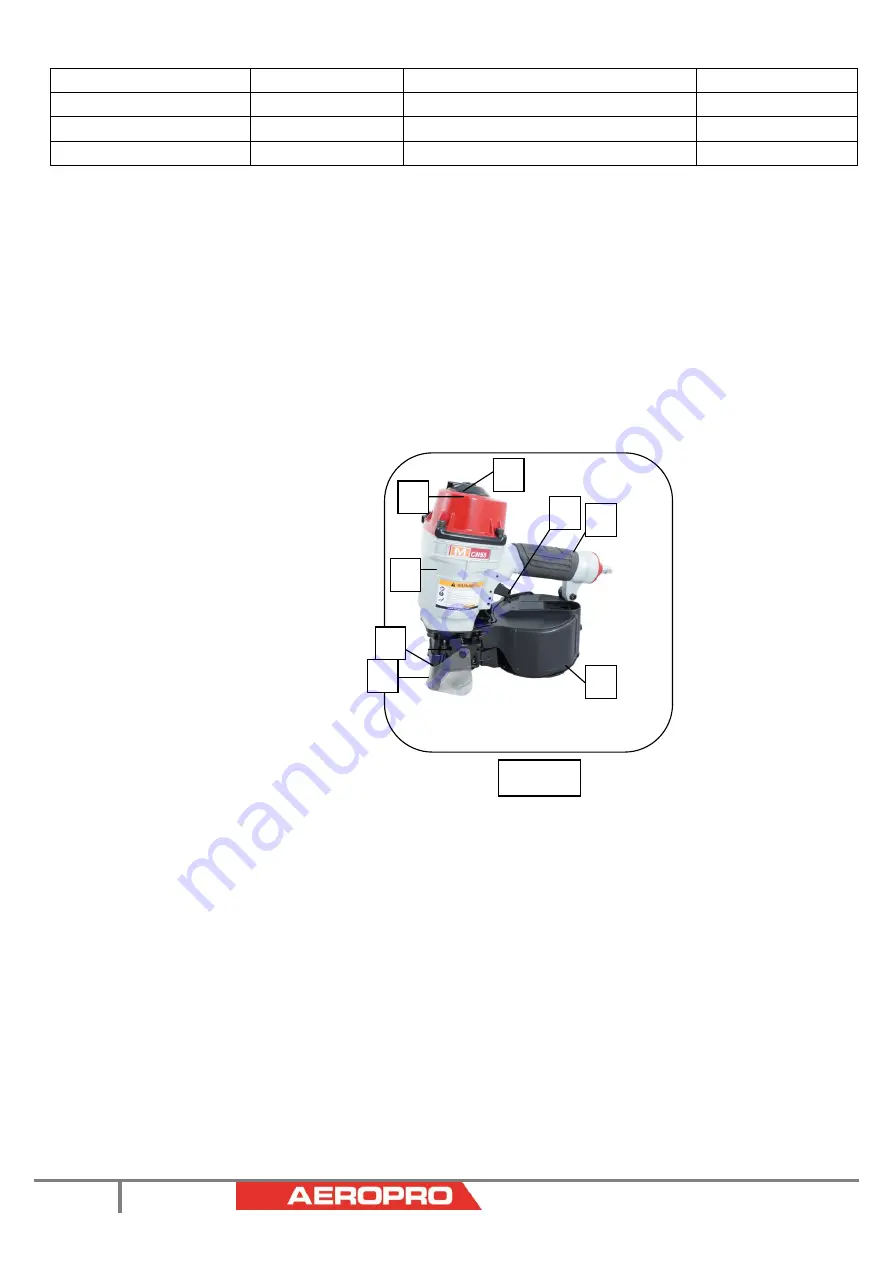

1.4 location of Parts

(see Figure 1)

1-Gun body

2-Cylinder Cap

3-Safety yoke

4.Nose Assembly

5-Magazine

6-Trigger

7-Grip

8- Exhaust Cover

2. Special references

2.1 Instructions

The following standard is applicable to fastener driving tools; EN792-13:2000+A1:2008

”Hand-held non-electric

power tools-safety requirements

– Part 13: Fastener driving tools”.

This standard requires that

-

only those fasteners which are specified in the operating instructions (see TECHNICAL DATA)shall be used

in fastener driving tools. The fastener driving tool and the fasteners specified in the operating instructions are

to be considered as one unit safety system;

-

quick action couplings shall be used for connection to the compressed air system and the non-sealable

nipple must be fitted at the tool in such a way that no compressed air remains in the tool after disconnection;

-

oxygen or combustible gases shall not be used as an energy source for compressed air operated fastener

driving tools;

-

fastener driving tools shall only be connected to an air-supply where the maximum allowable pressure of the

tool cannot be exceeded by more than 10%;in the case of higher pressure ,a pressure reducing valve which

includes a downstream safety valve shall be built into the compressed air supply;

-

only spare parts specified by the manufacturer or his authorized representative shall be used in the repair of

fastener driving tools;

1

2

8

6

7

5

4

3

Figure 1

Summary of Contents for MCN55

Page 8: ......