7

Heavy Duty 1

Air Impact Wrench RP7495

※

Maintenance

WARNING:

Disconnect wrench from air supply before changing accessories, servicing or performing

maintenance. Replace or repair damaged parts.

Use genuine parts only. Non-authorised parts may be dangerous.

1. Lubricate the air wrench daily with a few drops of air tool oil dripped into the air inlet

2 DO NOT use worn, or damaged sockets.

3. Loss of power or erratic action may be due to the following:

a)

Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or type of hose

connectors. To remedy check the air supply and follow instructions.

b)

Grit or gum deposits in the wrench may also reduce performance. If your model has an air strainer (located

in the area of the air inlet), remove the strainer and clean it.

4. When not in use, disconnect from air supply, clean wrench and store in a safe, dry, childproof location.

※

Trouble Shooting

The following form lists the common operating system with problem and solutions. Please read the form

carefully and follow it.

WARNING:

If any of the following symptoms appears during your operating, stop using the tool immediately,

or serious personal injury could result. Only a qualified persons or an authorized service center can perform repairs or

replacement of tool.

Disconnect tool from air supply before attempting repair or adjustment. When replacing O-rings or Cylinder,

lubricate with air tool oil before assembly.

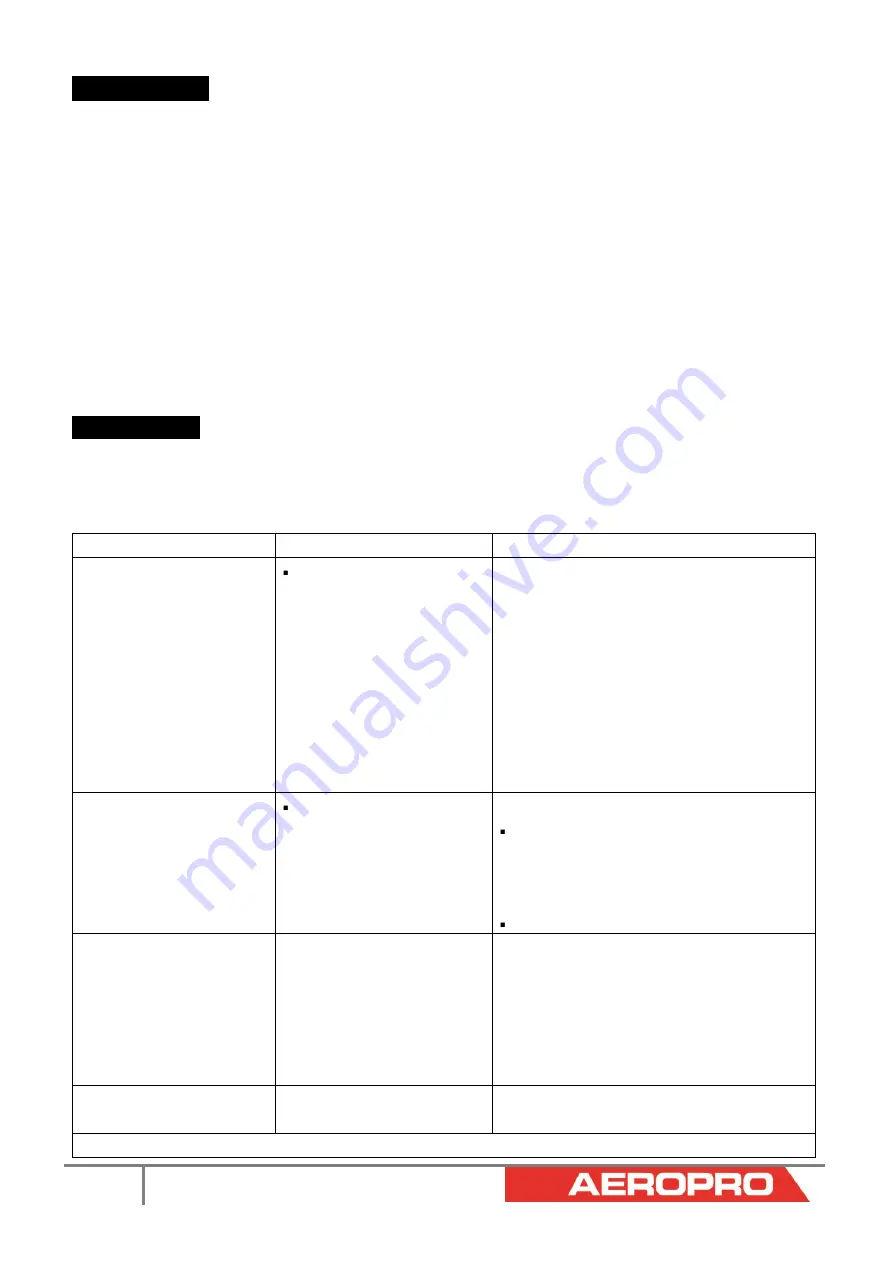

PROBLEMS

POSSIBLE CAUSES

REMEDIES

Tool runs at normal speed

but loses under load

Motor parts worn.

■

Cam clutch worn or sticking

due to lack of lubricant.

■

Lubricating clutch housing.

■

Check for excess clutch oil. Clutch cases need

only be half full. Overfilling

can cause drag on high speed clutch parts, ie. a

typical oiled/lubricated wrench requires 1⁄2

ounce of oil.

GREASE LUBRICATED:NOTE:

Heat

usually indicates insufficient grease in chamber.

Severe operating conditions may require more

frequent lubrication.

Tool runs slowly. Air flows

slightly from exhaust

Motor parts jammed with dirt

particles

■

Power regulator in closed

position

■

Air flow blocked by dirt.

■

Check air inlet filter for blockage.

Pour air tool lubricating oil into air inlet as

per instructions.

■

Operate tool in short bursts quickly reversing

rotation back and forth where applicable.

Repeat above as needed.

Tools will not run. Air flows

freely from exhaust

■

One or more motor vanes

stuck due to material build up.

■

Pour air tool lubricating tool into air inlet.

■

Operate tool in short bursts of forward and/or

reverse rotation where applicable.

■

Tap motor housing gently with plastic mallet.

■

Disconnect supply. Free motor by rotating

drive shank manually where applicable

Tool will not shut off

■

„O‟ rings throttle valve

dislodged from seat inlet valve.

■

Replace „O‟ ring.

Note: Repairs should be carried out by a qualified person.