19

G

B

Before using the compressor, read the instructions for use carefully and

comply with the following safety precautions. Consult this handbook if

you have any doubts regarding functioning.

Preserve all the documentation so that anyone who uses the

compressor can consult this beforehand.

SAFETY RULES

1

This symbol indicates warnings to be read before using the product so as

to prevent injury to the user.

Compressed air is a potentially dangerous form of energy; always take

great care when using the compressor and its accessories.

Warning: the compressor may restart when power is restored following

a blackout.

An ACOUSTIC PRESSURE value of 4 m. corresponds to the ACOUSTIC

POWER value stated on the yellow label located on the compressor,

minus 20 dB.

THINGS TO DO

●

The compressor must be used in a suitable environment (well

ventilated with an ambient temperature of b5°C and +40°C)

and never in places affected by dust, acids, vapors, explosive or

flammable gases

.

●

Always maintain a safety distance of at least 4 meters between the

compressor and the work area.

●

Any coloring of the belt guards of the compressor during painting operations

indicates that the distance is too short.

●

Insert the plug of the electric cable in a socket of suitable shape, voltage

and frequency complying with current regulations.

●

Use extension cables with a maximum length of 5 meters and of suitable

cross-section.

●

The use of extension cables of different length and also of adapters and

multiple sockets should be avoided.

●

Always use the switch

I/O

to switch off the compressor.

●

Always use the handle to move the compressor.

●

When operating, the compressor must be placed on a stable, horizontal

surface.

THINGS

NOT

TO DO

●

Never direct the jet of air towards persons, animals or your body. (Always

wear safety goggles to protect your eyes against flying objects that may be

lifted by the jet of air).

●

Never direct the jet of liquids sprayed by tools connected to the compressor

towards the compressor.

●

Never use the appliance with bare feet or wet hands or feet.

●

Never pull the power cable to disconnect the plug from the socket or to

move the compressor.

●

Never leave the appliance exposed to adverse weather conditions.

●

Never transport the compressor with the receiver under pressure.

●

Do not weld or machine the receiver. In the case of faults or rusting, replace

the entire receiver.

●

Never allow inexpert persons to use the compressor. Keep children and

animals at a distance from the work area.

●

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning the use of the appliance by a person responsible for their

safety.

●

Children should be supervised to ensure that they do not play with the

appliance.

●

Do not position flammable or nylon/fabric objects closed to and/or on the

compressor.

●

Never clean the compressor with flammable liquids or solvents. Check that

you have unplugged the compressor and clean with a damp cloth only.

●

The compressor must be used only for air compression. Do not use the

compressor for any other type of gas.

●

The compressed air produced by the compressor cannot not be used

for pharmaceutical, food or medical purposes except after particular

treatments and cannot be used to fill the air bottles of scuba divers.

THINGS YOU SHOULD KNOW

●

To avoid overheating of the electric motor, this compressor is

designed for intermittent operation as indicated on the technical

dataplate

(for example, S3-25 means 2.5 minutes ON, 7.5 minutes OFF). In

the case of overheating, the thermal cutout of the motor trips, automatically

cutting off the power when the temperature is too high. The motor restarts

automatically when normal temperature conditions are restored.

●

All the compressors are fitted with a safety valve that is tripped in the case

of malfunctioning of the pressure switch in order to assure machine safety.

●

When fitting a tool, the flow of air in output must be switched off.

●

The red notch on the pressure gauge refers to the maximum operating

pressure of the tank. It does not refer to the adjusted pressure.

●

When using compressed air, you must know and comply with the safety

precautions to be adopted for each type of application (inflation, pneumatic

tools, painting, washing with water-based detergents only, etc.).

●

Do not cover the air inlets on the compressor.

●

Do not open or tamper with any part of the compressor. Contact an

authorized Service Center.

ASSEMBLY

2

You must fully assemble the appliance before using it for the first time.

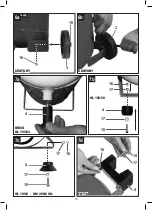

Fitting the wheels (Fig. 3, 4, 5 & 6)

Fit the supplied wheels as shown in Fig. 3, 4, 5 & 6:

● Fig. 3a & 3b: Assembly of wheel kit - version A

Assembly by sequence: a, b, c, d, e

● Fig. 4a & 4b: Assembly of wheel kit - version B

● Fig. 5a & 5b: Assembly of wheel kit - version C

● Fig. 6a & 6b: Assembly of wheel kit - version D

Fitting the rubber foot (ref. 4)

Fit the supplied rubber stopper as shown in Fig. 7.

START-UP AND USE

3

●

Check for correspondence between the compressor plate data with the

actual specifications of the electrical system. A variation of ± 10% with

respect of the rated value is allowed.

●

Insert the plug of the power cable in a suitable socket checking that the

I/O

switch located on the compressor is in the OFF «O» position.

●

At this point, the compressor is ready for use.

●

Operating on the

I/O

switch, the compressor starts, pumping air into the

receiver through the delivery pipe.

●

When the upper calibration value (set by the manufacturer) has been

reached, the compressor stops.

When air is used, the compressor restarts automatically when the lower

calibration value is reached (2 bar between upper and lower).

●

The pressure in the receiver can be checked on the gauge provided.

●

The compressor continues to operate according to this automatic cycle

until the

I/O

switch is turned.

●

Always wait at least 10 seconds from when the compressor has been

switched off before restarting this.

●

All compressors are fitted with a pressure reducer (ref. 7). Operating on the

knob with the tap open (turning it in a clockwise direction to increase the

pressure and in a counterclockwise direction to reduce it), air pressure can

be regulated so as to optimize use of pneumatic tools

.

●

The value set can be checked on the gauge (ref. 6).

●

The set pressure can be taken from the quicklock coupling (ref. 5).

●

Please check that the air consumption and the maximum working

pressure of the pneumatic tool to be used are compatible with the

pressure set on the pressure regulator and with the amount of air

supplied by the compressor.

●

Always pull out the plug and drain the receiver once you have completed

your work.

Preserve this handbook for future reference

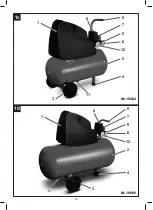

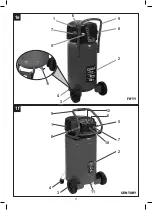

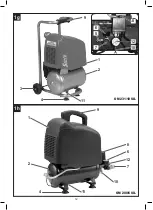

COMPONENTS (fig. 1 - 2 - 3 - 4 - 5 - 6)

1.

Shroud

10.

Safety valve

2.

Pressure vessel (tank)

11.

Receiver condensation drainage tap

3.

Wheel

12.

Pressure gauge (for reading the tank

pressure)

4.

Rubber foot

13.

Axle

5.

Quick-lock coupling (regulated

compressed air)

14.

Clip

6.

Pressure gauge (for reading the preset

pressure by means of regulator)

15.

Screw

7.

Pressure regulator

16.

Nut

8.

I/O

switch

17.

Washer

9.

Transportation handle

Summary of Contents for BRICO

Page 9: ...9 1a 1b 2 1 1 11 4 11 10 5 7 BRICO OL 195 6 6 4 6 3 9 7 5 2 9...

Page 10: ...10 1c 1d 2 1 1 11 3 OL 195 24 OL 195 50 4 8 8 3 9 5 7 6 12 2 9 5 7 6 12 4 11...

Page 11: ...11 1e 9 8 2 5 FIFTY 6 4 3 11 1 7 1f CENTURY 5 6 12 2 7 10 8 4 3 11 9 1...

Page 12: ...12 1h 1 4 11 10 7 OM 200 6 SIL 12 2 9 8 6 1g OM 231 10 SIL 11 2 1 9 3 4 12 8 7 6 5 10...

Page 16: ...16 7e 15 17 4 16 CENTURY...

Page 38: ...38 G R 2 bar I O 10 7 6 5 4 2 11 5...

Page 52: ...52 R U O 2 10 7 6 5 4 11 5...

Page 60: ...60 B G 2 I O 10 7 6 5 4 11 5...

Page 69: ...63 230V Ac 50 Hz 120V Ac 60 Hz 230V Ac 50 Hz 120V Ac 60 Hz 69...

Page 70: ...63 230V Ac 50 Hz 120V Ac 60 Hz 230V Ac 50 Hz 120V Ac 60 Hz 70...

Page 71: ...63 230V Ac 50 Hz 120V Ac 60 Hz 230V Ac 50 Hz 120V Ac 60 Hz 71...