Mechanical Specifications and Installation

ABL1000 Hardware Manual

2.3. Securing the Stage to the Mounting Surface

The mounting surface must be flat and have adequate stiffness in order to achieve the maximum

performance from the ABL1000 stage. When it is mounted to a non-flat surface, the stage can be distorted

as the mounting screws are tightened. This distortion will decrease overall accuracy. Adjustments to the

mounting surface must be done before the stage is secured.

W A R N I N G : Make sure that all moving parts are secure before moving the ABL1000.

Unsecured moving parts may shift and cause bodily injury.

D A N G E R : Strong rare-earth magnets are present in the linear motor magnet track. Loose

metal objects (tools, watches, keys, etc.) may cause personal injury and/or damage to the

equipment.

W A R N I N G : The ABL1000 must be mounted securely. Improper mounting can result in injury

and damage to the equipment.

N O T E :

To maintain accuracy, the mounting surface must be flat to within 1 µm per 50 mm.

N O T E :

The stage base is precision machined and verified for flatness prior to stage assembly at the

factory. If machining is required to achieve the desired flatness, it should be performed on the mounting

surface rather than the stage base. Shimming should be avoided if possible. If shimming is required, it

should be minimized to improve the rigidity of the system.

Procedure to mount the ABL1000:

W A R N I N G : Do not attempt to move the carriage of the ABL1000 until the air supply, detailed

in

, has been installed. Moving the stage table without air supplied can cause

permanent damage to the stage.

1. Supply air to the stage with the air inlet. Refer to

for more information on air supply.

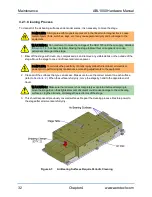

2. Manually move the stage to one end of travel. Half of the mounting holes for the stage will show. See

3. Mount the stage to the base with M5 screws. The number of mounting holes depends on stage travel.

4. After half of the mounting screws are installed, move the stage to the opposite end of travel to access

the remaining screws. Repeat the installation process for these holes.

18

Chapter 2

www.aerotech.com