Electrical Specifications and Installation

ABL1000WB Hardware Manual

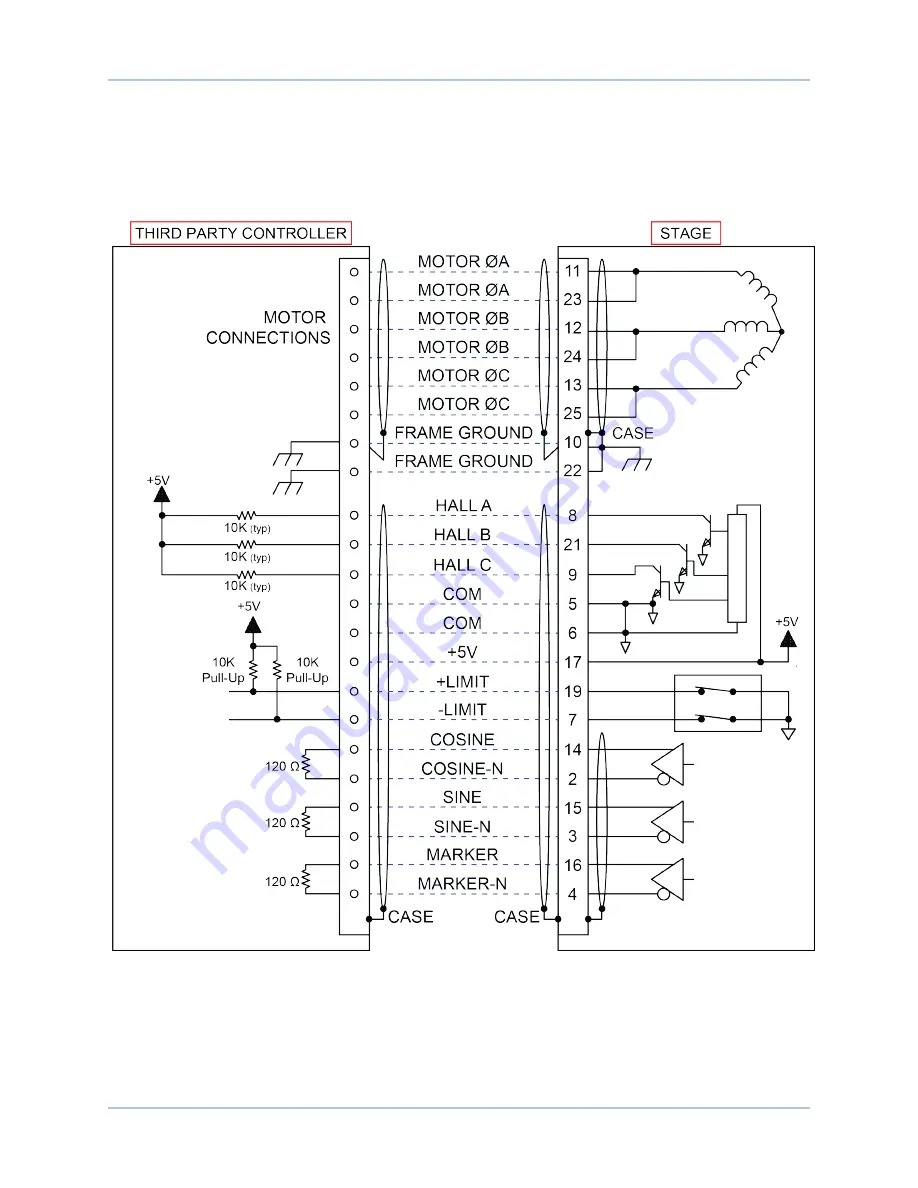

3.2. Motor and Feedback Wiring

All motor and controller manufacturers have their own designations for motor phases A/B/C and Hall signals

A/B/C (refer to

Section 3.5.

for motor phasing). Shielded cables are required for the motor and feedback

connections.

Figure 3-1:

Motor and Feedback Wiring

24

Chapter 3

www.aerotech.com